High temperature-resistant methanation catalyst preparation method

A methanation catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of poor thermal stability and carbon deposition resistance of catalysts, Hexaaluminate carrier has low specific surface area and high catalyst reduction temperature to achieve the effect of high density, high mechanical strength and lower reduction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

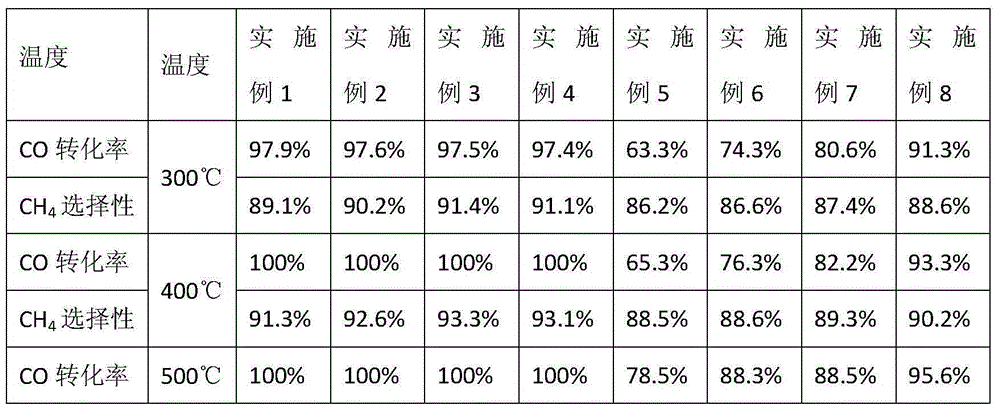

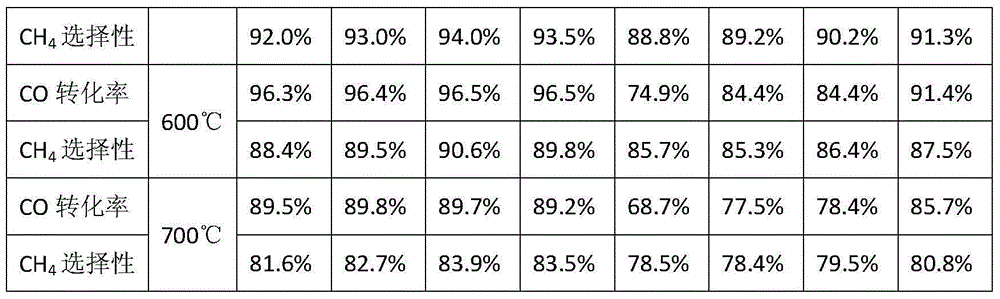

Examples

Embodiment 1

[0017] A preparation method of a high-temperature-resistant methanation catalyst, comprising the following steps:

[0018] Step A, catalyst semi-finished product:

[0019] 171.32g of Ni(NO 3 ) 2 ·6H 2 O, 17.58g of Ca(NO 3 ) 2 4H 2 O, 12.76g of La(NO 3 ) 3 ·6H 2 O and 89.74g of Mg(NO 3 ) 2 ·6H 2 O was dissolved in 500ml of deionized water to make mixed metal salt solution I, and then 129.83g of Na 2 CO 3 Dissolve in 500ml of deionized water to make alkaline solution II, maintain the constant temperature of alkaline solution II at 80°C, gradually add the mixed salt solution I into the alkaline solution II, and keep stirring for complete precipitation reaction, with pH = 8 as the titration end point After the precipitation, add 7ml of silica sol, stir well and age at 90°C for 2 hours, wash the precipitated precursor with deionized water three times; after suction filtration, dry the filter cake at 90°C for 8h, and roast at 400°C 4h, obtain catalyst semi-finished pro...

Embodiment 2

[0028] A preparation method of a high-temperature-resistant methanation catalyst, comprising the following steps:

[0029] Step A, catalyst semi-finished product:

[0030] 155.74g of Ni(NO 3 ) 2 ·6H 2 O, 29.30g of Ca(NO 3 ) 2 4H 2 O, 11.16g of La(NO 3 ) 3 ·6H 2 O and 76.92g of Mg(NO 3 ) 2 ·6H 2 O was dissolved in 500ml of deionized water to make mixed metal salt solution I, and then 124.54g of Na 2 CO 3 Dissolve in 500ml of deionized water to make alkaline solution II, keep the alkaline solution II at a constant temperature of 70°C, gradually add the mixed salt solution I into the alkaline solution II, and keep stirring for complete precipitation reaction, with pH = 8 as the titration end point After the precipitation, add 10ml of silica sol, stir well and age at 80°C for 2 hours, wash the precipitated precursor with deionized water three times; dry the filter cake at 100°C for 12h after suction filtration, and roast at 450°C 6h, obtain catalyst semi-finished pro...

Embodiment 3

[0039] A preparation method of a high-temperature-resistant methanation catalyst, comprising the following steps:

[0040] Step A, catalyst semi-finished product:

[0041] 147.96g of Ni(NO 3 ) 2 ·6H 2 O, 38.09g of Ca(NO 3 ) 2 4H 2 O, 9.57g of La(NO 3 ) 3 ·6H 2 O and 70.50g of Mg(NO 3 ) 2 ·6H 2 O was dissolved in 500ml of deionized water to make mixed metal salt solution I, and then 124.58g of Na 2 CO 3 Dissolve in 500ml of deionized water to make alkaline solution II, maintain the constant temperature of alkaline solution II at 80°C, gradually add the mixed salt solution I into the alkaline solution II, and keep stirring for complete precipitation reaction, with pH = 8 as the titration end point After the precipitation, add 14ml of silica sol, stir well and age at 90°C for 2 hours, wash the precipitated precursor with deionized water three times; dry the filter cake at 90°C for 12h after suction filtration, and roast at 500°C 4h, obtain catalyst semi-finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com