Horizontal spiral ribbon mixer and technology for processing of trionyx sinensis feed by the same

A mixer and horizontal screw technology, applied in the field of machinery, can solve the problems of insufficient mixing uniformity of raw materials, deviation of nutrient components between soft-shelled turtles and uneven soft-shelled turtles, etc., so as to improve mixing efficiency, facilitate ultra-fine grinding, Improve the effect of blending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

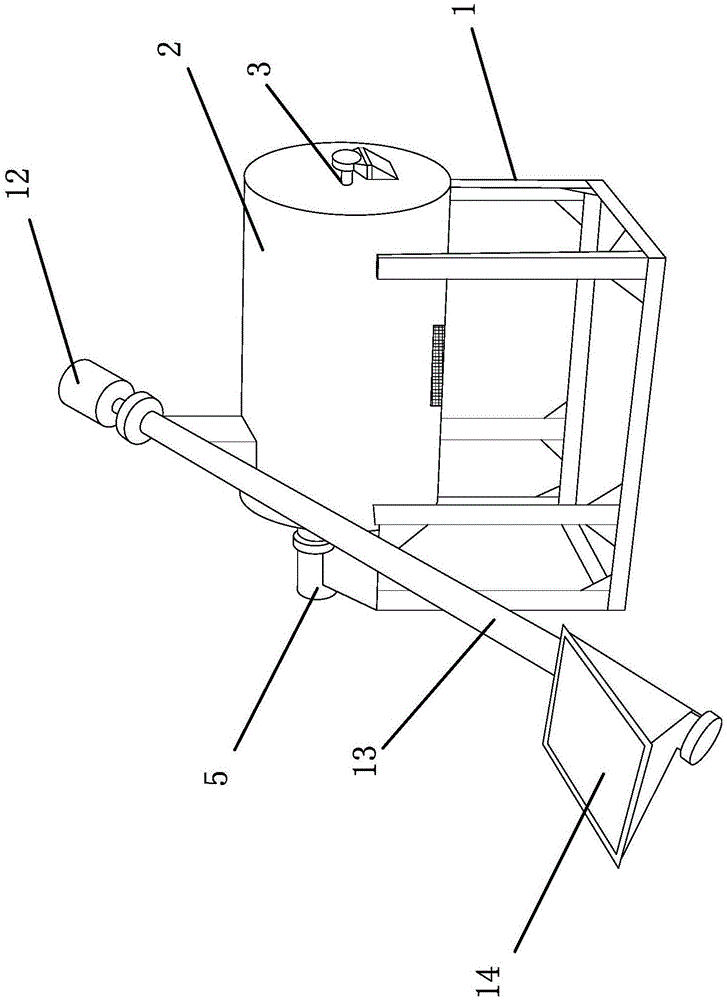

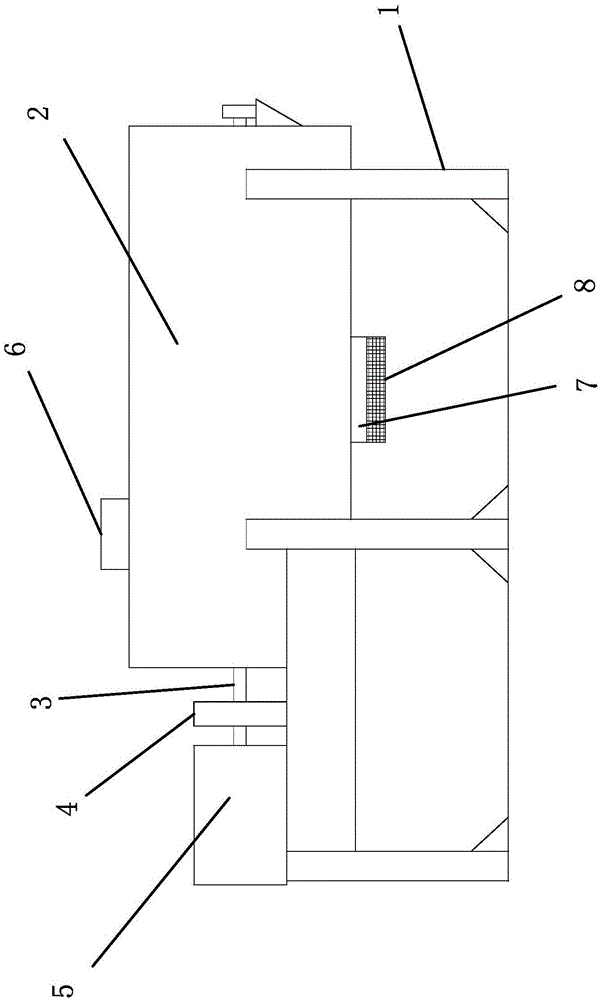

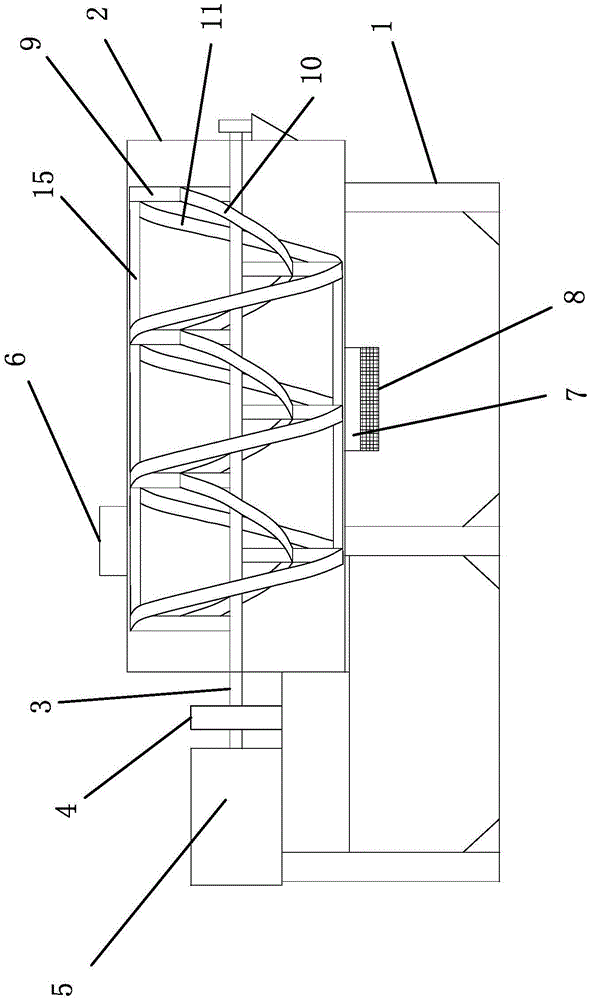

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0033] Such as figure 1 , figure 2 , image 3 As shown, the horizontal ribbon mixer includes a base 1 and a cylindrical mixing barrel 2 fixed on the base 1, and is characterized in that a main shaft 3 runs through the axis of the mixing barrel 2 One end of the main shaft 3 is dynamically connected with the motor 5 fixed on the base 1 through the reducer 4, and the other end of the main shaft 3 is connected to the base 1 through the rotation of the bearing. 2. The lower end is provided with a discharge port 7, and the discharge port 7 is provided with a discharge valve 8. The upper end of the mixing cylinder 2 also has some vent holes for quickly balancing the air pressure of the mixing cylinder 2.

[0034] The main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com