Battery with electrolyte mixing device

A technology of electrolyte and liquid electrolyte, applied in the direction of transferring electrolyte devices, batteries, secondary batteries, etc., can solve the problems of limiting vehicle acceleration, achieve high service life, improve service life, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

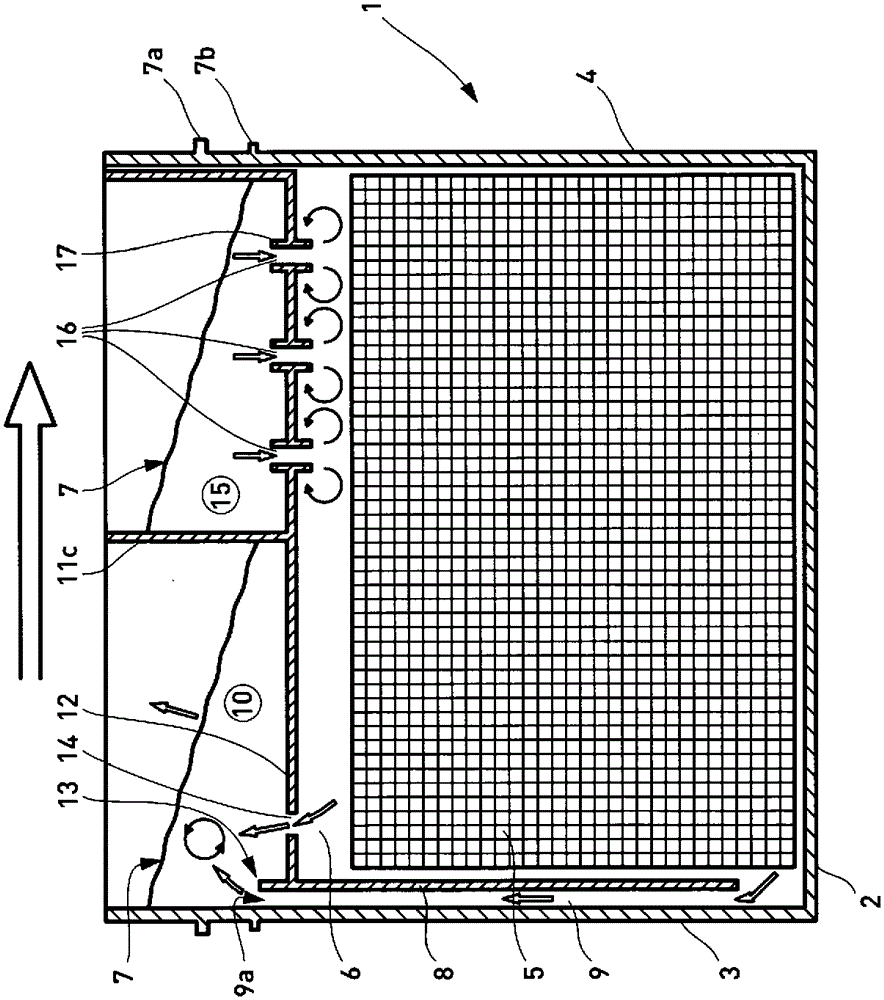

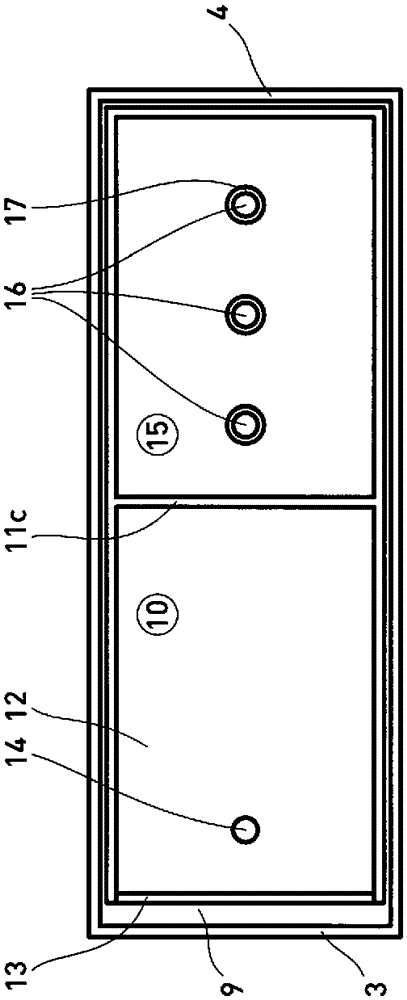

[0034] figure 1 A cross-sectional view of a battery box cell is shown. The battery box cell 1 has a rectangular cross-section with a bottom 2 and four side walls, only side walls 3 and 4 being visible in this view. The plate-shaped electrode is identified with reference numeral 5 and the battery acid with a fill level 7 between a maximum fill level 7a and a minimum fill level 7b is marked with a reference sign 6 . As can be seen from the figure, the level plotted is at the mark of the maximum level 7a.

[0035] A flow channel plate 8 is arranged vertically between the side wall 3 and the electrode 5 , thereby forming a flow channel 9 . The end of the flow channel 9 is thus an outflow groove 9 a.

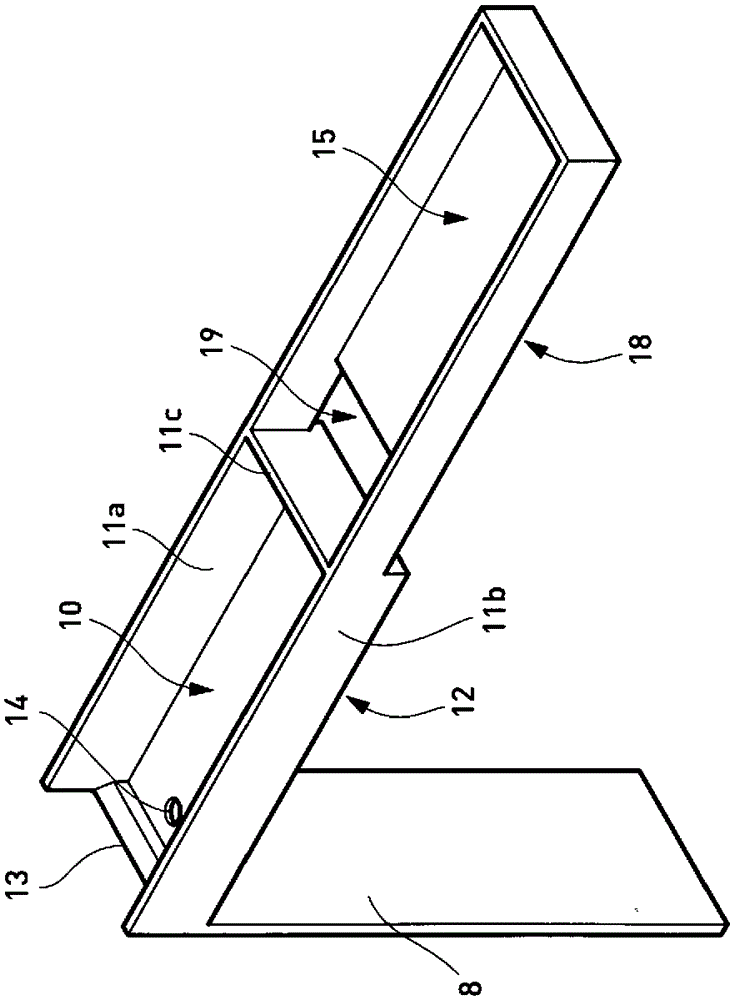

[0036] On the edge of the outflow trough 9a, a mixing basin 10 is arranged, which has side walls 11a, 11b, 11c and a bottom 12, wherein the side walls 11a and 11b can only be viewed in a perspective view. Figure 8 seen in. The upper end of the flow channel plate 8 forms an over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com