Nano-antibacterial plastic pipe having high-molecular carbon fiber composite skeleton

A fiber skeleton and polymer technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve problems such as hidden dangers, people's health, and bacteria breeding, and achieve high costs, prevent secondary pollution, and improve projects. The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

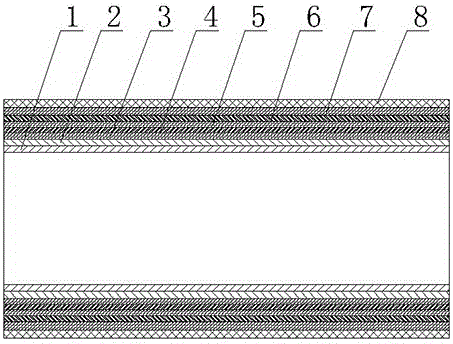

[0009] like figure 1 As shown, a plastic tube with a nano-antibacterial and high-molecular carbon fiber composite skeleton includes a nano-silver antibacterial plastic layer 1, a high-density polyethylene layer 2, a high-strength adhesive layer 3, and a metal skeleton sequentially arranged from the inside to the outside. Layer 4, high-strength adhesive layer 5, fiber skeleton layer 6, high-strength adhesive layer 7 and high-density polyethylene layer 8, the metal skeleton layer 4 is a network formed by spirally winding high-strength copper-plated steel wire left and right Skeleton structure, the fiber skeleton layer 6 is a network skeleton structure formed by helically winding polymer carbon fiber filaments left and right, and the thickness of the nano-silver antibacterial plastic layer 1 is 1.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com