Mechanical direct-connection and hydrostatic stepless parallel-connection tri-speed type dual-power input device

A technology of power input and input device, applied in the direction of transmission device, transmission device parts, fluid transmission device, etc., can solve the problems of low transmission efficiency, hydraulic transmission efficiency reduction, large fuel consumption, etc., and achieve the expansion of high-efficiency transmission range, generation or Easier release and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

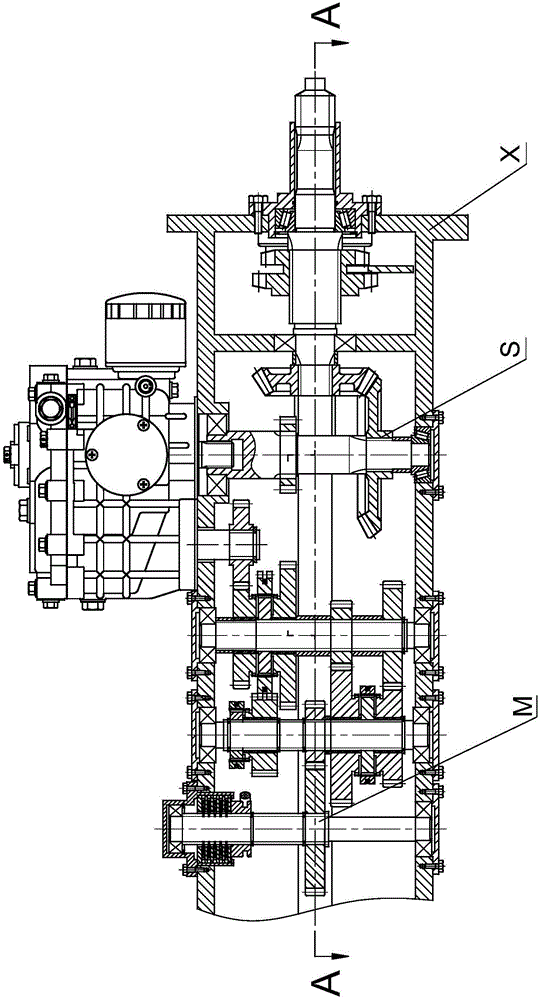

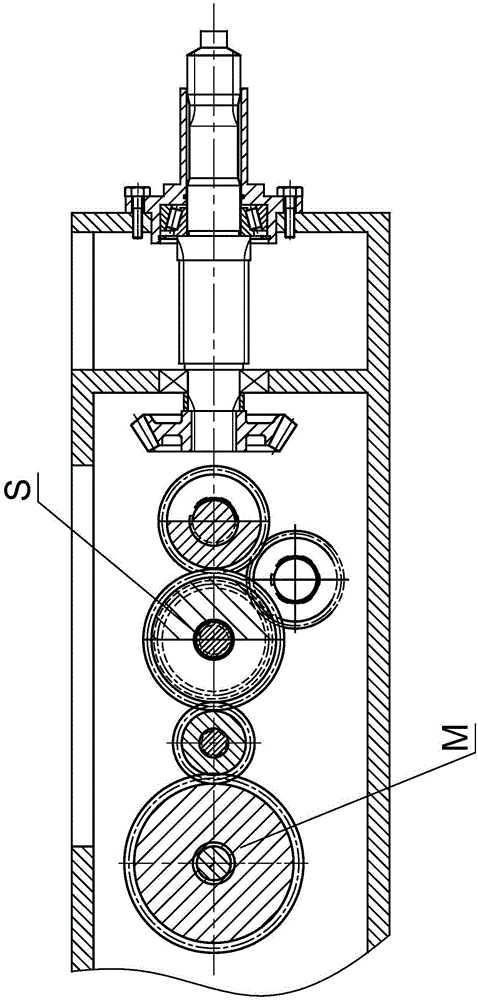

[0044] see Figure 1 ~ Figure 2 The mechanical direct connection and hydrostatic stepless parallel three-speed double power input device, which includes a double power input mechanism S installed on the box X and a three-speed transmission and braking mechanism M.

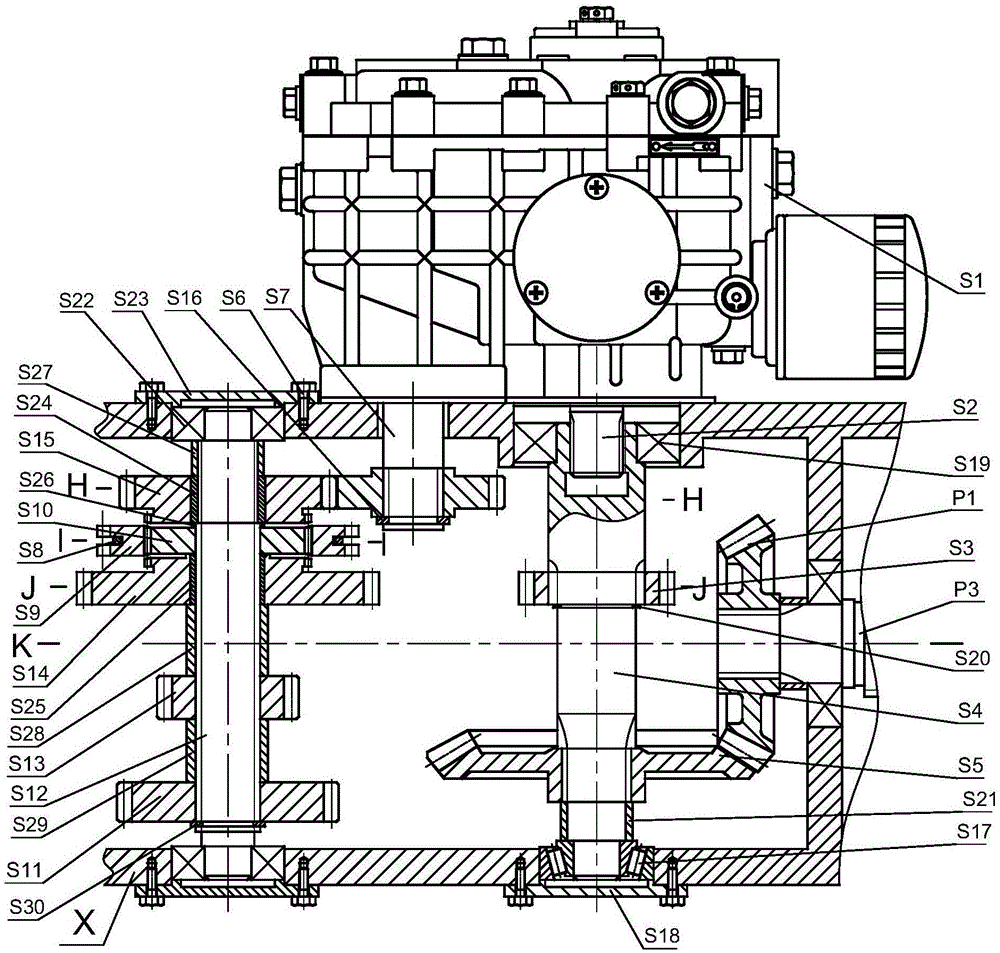

[0045] see Figure 3 ~ Figure 7 As shown, the dual power input mechanism S includes hydrostatic continuously variable transmission S1, hydrostatic continuously variable transmission power input shaft S2, mechanical gear driving gear S3, power input second shaft S4, driven bevel gear S5, hydrostatic continuously variable transmission Power output gear S6, hydrostatic continuously variable transmission power output shaft S7, shift fork S8, double power combination sleeve S9, double po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com