A Combined Shaft Structure Based on Wedge Key Connection

A rotating shaft structure and combined technology, applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of excessive heat conduction capacity and high structural temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

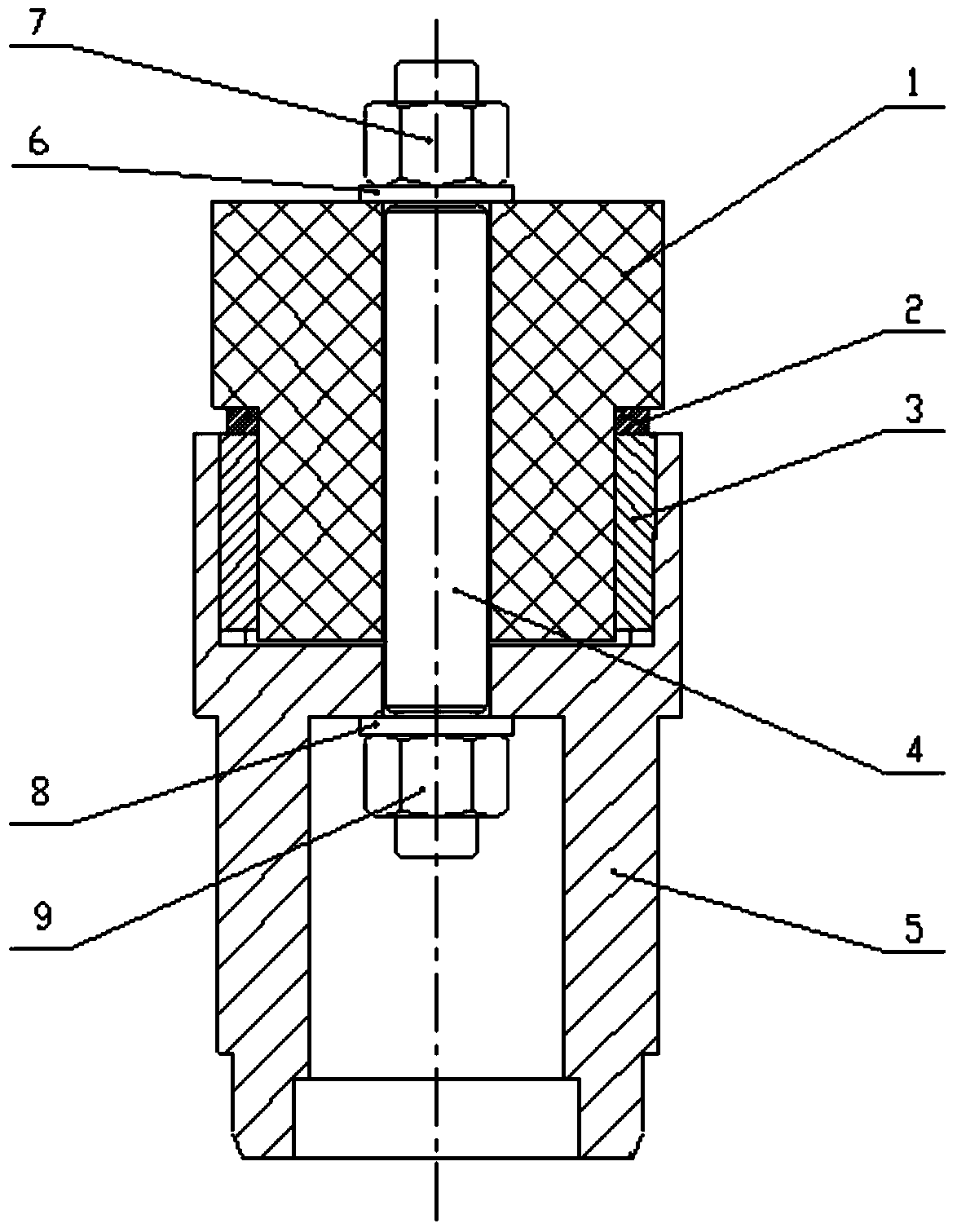

[0022] The present invention is a combined shaft structure based on wedge key connection, such as figure 1 As shown, it includes a carbon-carbon shaft 1, a pressure ring 2, two wedge keys 3, a connecting screw 4, a metal shaft 5, a first washer 6, a first lock nut 7, a second washer 8, and a second lock Tighten the nut 9.

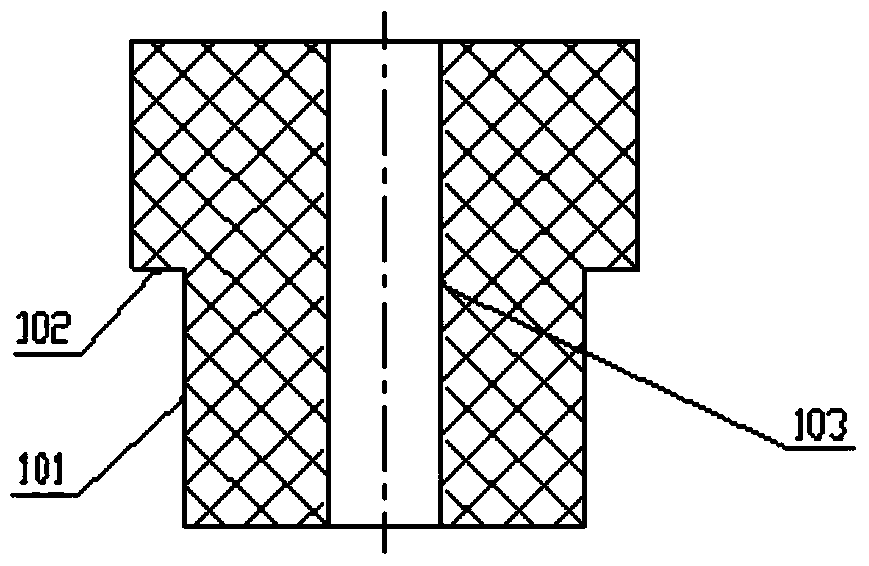

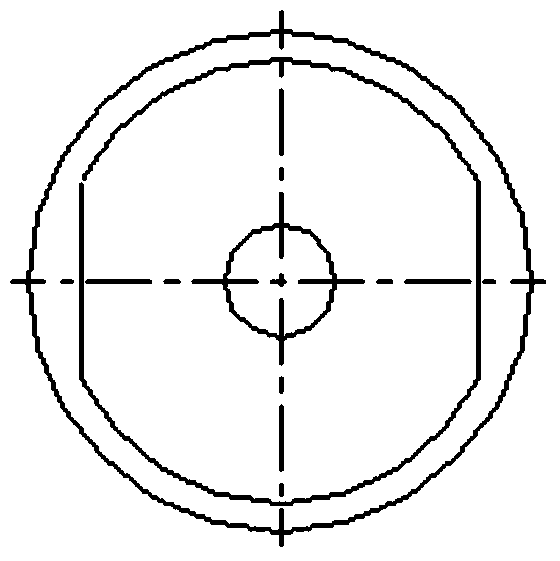

[0023] Such as figure 2 with image 3 As shown, the carbon-carbon rotating shaft 1 is made of carbon-carbon composite material and has a cylindrical platform structure. The diameter of the upper part of the cylindrical platform is larger than the diameter of the lower part. Cooperate; the outer wall of the lower part of the cylindrical pedestal is provided with two concave planes at a distance of 180 degrees along the circumferential direction, that is, the mating surface 101, and the mating surface 101 cooperates with the wedge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com