Hob mounting structure of shield tunneling machine

A technology for installing structures and shield machines, which is applied in mining equipment, earthwork drilling, tunnels, etc. It can solve problems such as the hob is easy to fall off, and achieve the effect of solving easy fall off, increasing stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

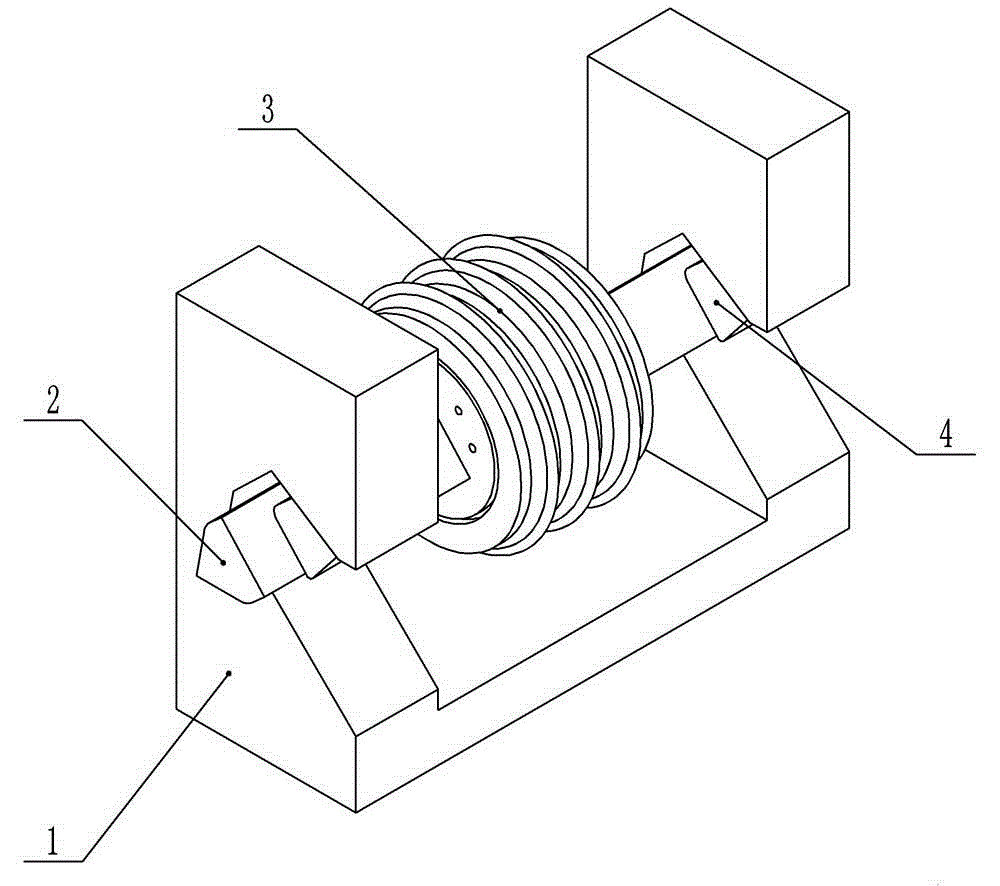

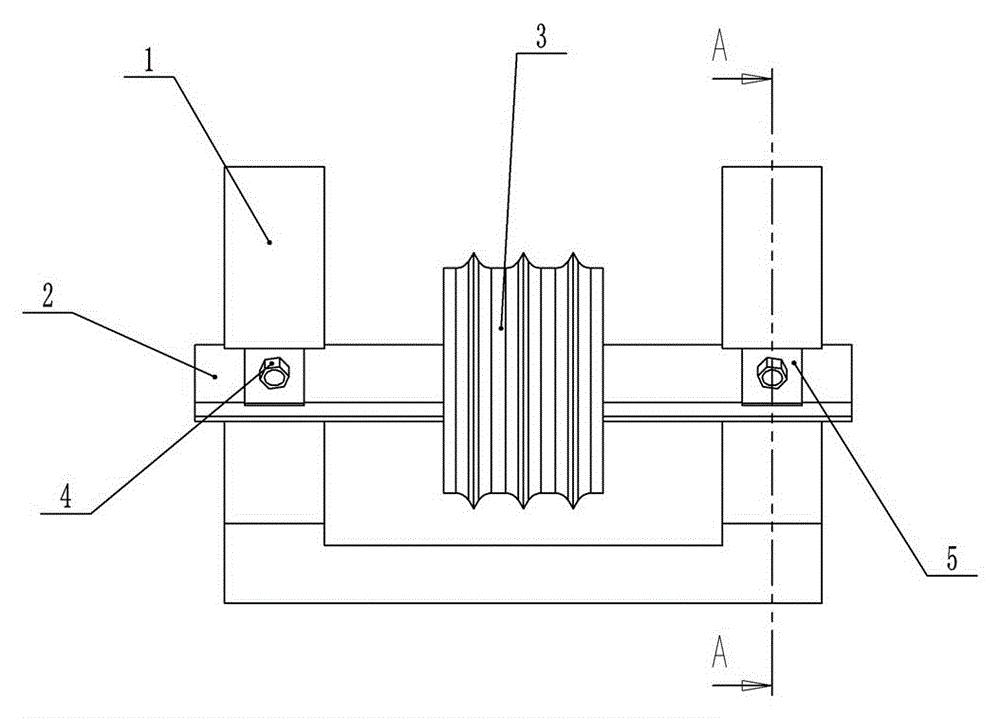

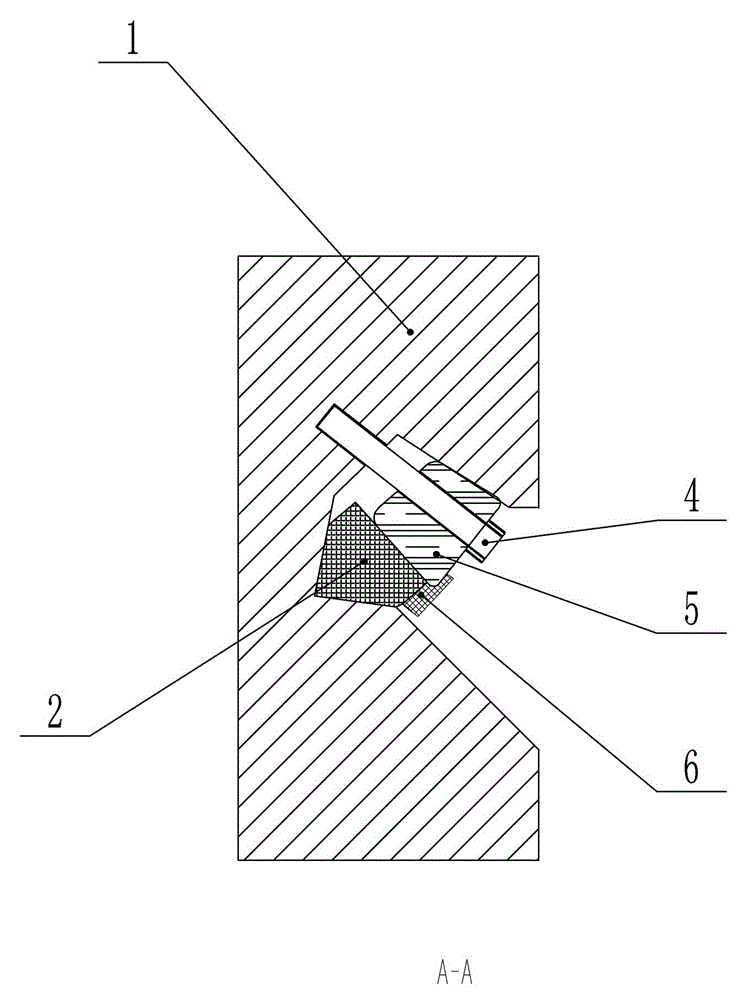

[0023] This embodiment provides a shield machine hob installation structure, such as figure 1 , figure 2 As shown, it includes a knife seat 1, a hob shaft 2, a hob 3, a wedge block 5 and a high-strength bolt 4. A groove is opened on the knife seat 1, and the hob shaft 2 and the wedge block 5 are accommodated in the groove. like image 3 As shown, the cross section of the hob shaft 2 is wedge-shaped, which can ensure that the hob shaft 2 cannot rotate in the groove of the tool holder 2, as shown in Figure 4 As shown, the wedge block 5 is provided with a through hole, and the diameter of the through hole is slightly larger than the outer diameter of the screw rod of the high-strength bolt 4 and smaller than the diameter of the bolt head of the high-strength bolt 4 . Additionally, if image 3 As shown, a stopper 6 is welded on the wedge block 5, and the stopper 6 has a good limiting effect on the hob shaft 2, reduces the vibration of the hob shaft 2, and prevents the hob sha...

Embodiment 2

[0028] This embodiment provides a shield machine hob installation structure, such as Figure 5 As shown, it includes a knife seat 1 , a hob 3 , a first wedge 8 , a second wedge 9 and a hob shaft 2 for fixing the hob 3 . The knife seat 1 is provided with threaded holes matching the high-strength special-shaped bolts 7, and the knife seat 1 is also provided with grooves for accommodating the hob shaft 2, the first wedge block 8 and the second wedge block 9, and the hob The cross section of shaft 2 is wedge-shaped. The hob shaft 2 is located between the first wedge block 8 and the second wedge block 9 and abuts against each other. like Image 6 As shown, the special-shaped bolt 7 includes a bolt head 700, a pressure plate 701 and a screw rod 702 connected in sequence, the bolt head 700, the pressure plate 701 and the screw rod 702 are integrally formed, and the second wedge block 9 is welded with a stopper 6 . The special-shaped bolt 7 is stuck between the first wedge block 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com