High-strength toughness low-medium carbon micro-alloyed air-cooled hardened spring steel and its forming and heat treatment process

A high-strength-toughness, spring steel technology, applied in the field of high-strength-toughness low-medium-carbon micro-alloy air-cooled hardened spring steel and its forming and heat treatment process, can solve the problem that the cross-section of spring parts is not too large and uniform, to simplify the process, reduce Manufacturing cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below.

[0037] The high-strength toughness low-medium carbon micro-alloy air-cooled hardening spring steel of the present invention, its basic idea is: this spring steel comprises the chemical composition of following weight percent:

[0038] C: 0.15% to 0.50%,

[0039] Si: 0.30%~2.00%,

[0040] Mn: 0.60% to 2.50%,

[0041] S: ≤0.020%,

[0042] P: ≤0.025%,

[0043] B: 0.0005% to 0.0035%,

[0044] The balance is iron.

[0045] Further, the spring steel also contains at least one of the following chemical components in percentage by weight:

[0046] Mo: 0.10% to 0.50%,

[0047] Cr: 0.20%~1.00%; or / and

[0048] Contains at least one of the following chemical constituents (microalloying elements) in weight percent:

[0049] V: 0.03%~0.12%,

[0050] Nb: 0.02%~0.1%,

[0051] Ti: 0.005% to 0.5%.

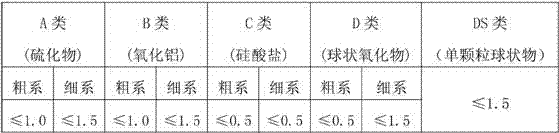

[0052] The H content in the rolled spring steel is ≤0.8ppm, the O content is ≤15ppm, and the N content is 50ppm-130ppm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com