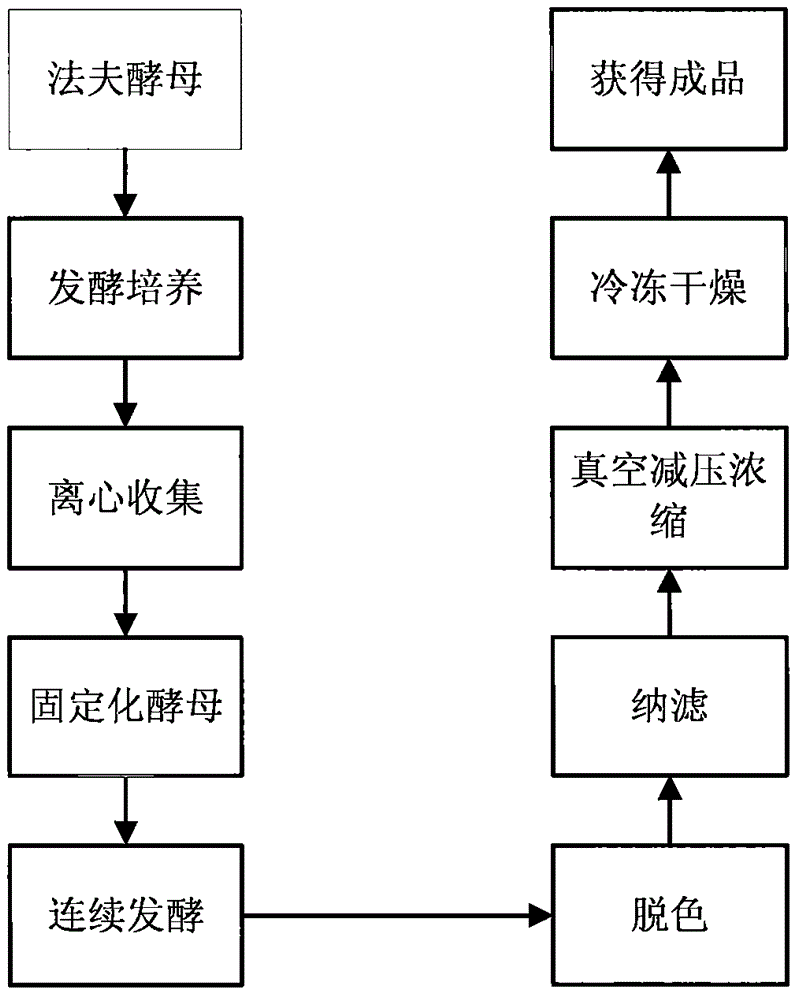

Production process of fructo-oligosaccharide-neokestose

A new cos sugar and cos sugar technology, applied in the field of bioengineering, can solve the problems of no patent reports on new cos sugar, and achieve the effect of high activity of embedded live bacteria, avoiding direct mixing, and convenient separation of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of bacteria:

[0037] Pick a ring of bacteria from the slant and place it in a 250mL shaker flask containing 25mL medium, culture it on a shaking table at 18°C and 180r / min for 48h to obtain the primary seed liquid; then inoculate the primary seed culture liquid into 100mL of the above culture In a 500mL Erlenmeyer flask based on the base, 18°C, 180r / min shaker culture for 48h to get the secondary seed solution; inoculate the secondary seed solution with 10% of the inoculum to the fermenter, pH6.0, culture temperature 18°C, ventilation volume: 0.6vvm, the stirring speed was 160r / min, the fermentation time was 24h, and the fermentation broth was centrifuged at 4°C and 5000rpm for 10min to obtain Phaffia yeast cells.

[0038] The composition of the seed medium is: 10g sucrose, 3g peptone, 2g yeast extract, 2g wort juice, 1000mL water, pH6.0;

[0039]The composition of the fermentation medium is: 30 g of sucrose, 3 g of peptone, 2 g of yeast extract, 2 g...

Embodiment 2

[0050] (1) Preparation of bacteria:

[0051] Pick a ring of bacteria from the slant and place it in a 250mL shaker flask containing 25mL medium, and culture it on a shaker at 22°C and 180r / min for 32h to obtain a first-grade seed solution; then inoculate the first-grade seed culture solution into 100mL of the above In the base 500mL conical flask, 22 ℃, 180r / min shaker culture 32h obtains the secondary seed liquid; Inoculate the secondary seed liquid with 12% of the inoculum to the fermenter, pH6.2, culture temperature 22 ℃, ventilation volume: 0.8vvm, the stirring speed is 200r / min, the fermentation time is 32h, and the fermentation liquid is centrifuged at 4°C and 5000rpm for 10min to obtain Phaffia yeast cells.

[0052] The composition of the seed medium is: 30g sucrose, 5g peptone, 4g yeast extract, 4g wort juice, 1000mL water, pH6.2;

[0053] The composition of the fermentation medium is: 60g of sucrose, 5g of peptone, 4g of yeast extract, 4g of wort juice, 1000mL of wat...

Embodiment 3

[0064] (1) Preparation of bacteria:

[0065] Pick a ring of bacteria from the slant and place it in a 250mL shaker flask containing 25mL medium, and culture it on a shaking table at 28°C and 180r / min for 24h to obtain a first-grade seed liquid; then inoculate the first-grade seed culture liquid into 100mL of the above In the base 500mL conical flask, 28 ℃, 180r / min shaker culture 24h obtains the secondary seed liquid; Inoculate the secondary seed liquid with 15% of the inoculum to the fermenter, pH6.5, culture temperature 28 ℃, ventilation volume: 1.0vvm, the stirring speed is 220r / min, the fermentation time is 24h, and the fermentation liquid is centrifuged at 4°C and 5000rpm for 10min to obtain Phaffia yeast cells.

[0066] The composition of the seed medium is: 50g sucrose, 8g peptone, 8g yeast extract, 6g wort juice, 1000mL water, pH6.5;

[0067] The composition of the fermentation medium is: 100 g of sucrose, 8 g of peptone, 8 g of yeast extract, 6 g of wort juice, 1000 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com