New rubber suspension assembly

A suspension assembly and rubber technology, applied in the field of auto parts manufacturing, can solve problems such as poor service life and maintainability, failure to meet lightweight requirements, and bulky overall design, so as to protect drivers, improve fuel economy, and overall The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

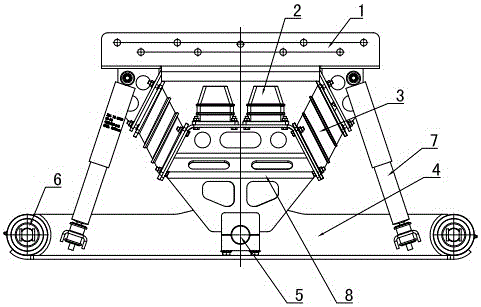

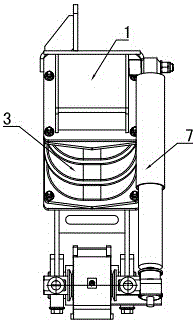

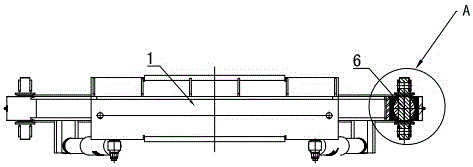

[0034] Figure 1-8 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1-8 The present invention is described further:

[0035] Refer to attached Figure 1-4 : The new rubber suspension assembly includes a rubber suspension fixed welding plate 1 and a rubber suspension main welded equalizer beam 4 arranged parallel to each other, and the rubber suspension fixed welded plate 1 and the rubber suspension main welded equalizer beam 4 are all steel plates Formed by welding, the rubber suspension fixed welding plate 1 is provided with a plurality of bolt connection holes.

[0036] The rubber suspension main spring 3 is installed between the rubber suspension fixed welding plate 1 and the rubber suspension main welding equalization beam 4, and the upper left and right sides of the rubber suspension main spring 3 are respectively provided with support frames, and the support frames are connected to the rubber suspension fixed welding T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com