Device for removing oddments on mouth of packaging bottle

A technology for packaging bottles and residual materials, which is applied in the field of packaging bottle processing, can solve the problem of not being able to remove residual materials from the bottle mouth along the radial direction, and achieves the effects of thorough removal, good effect and fast removal speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

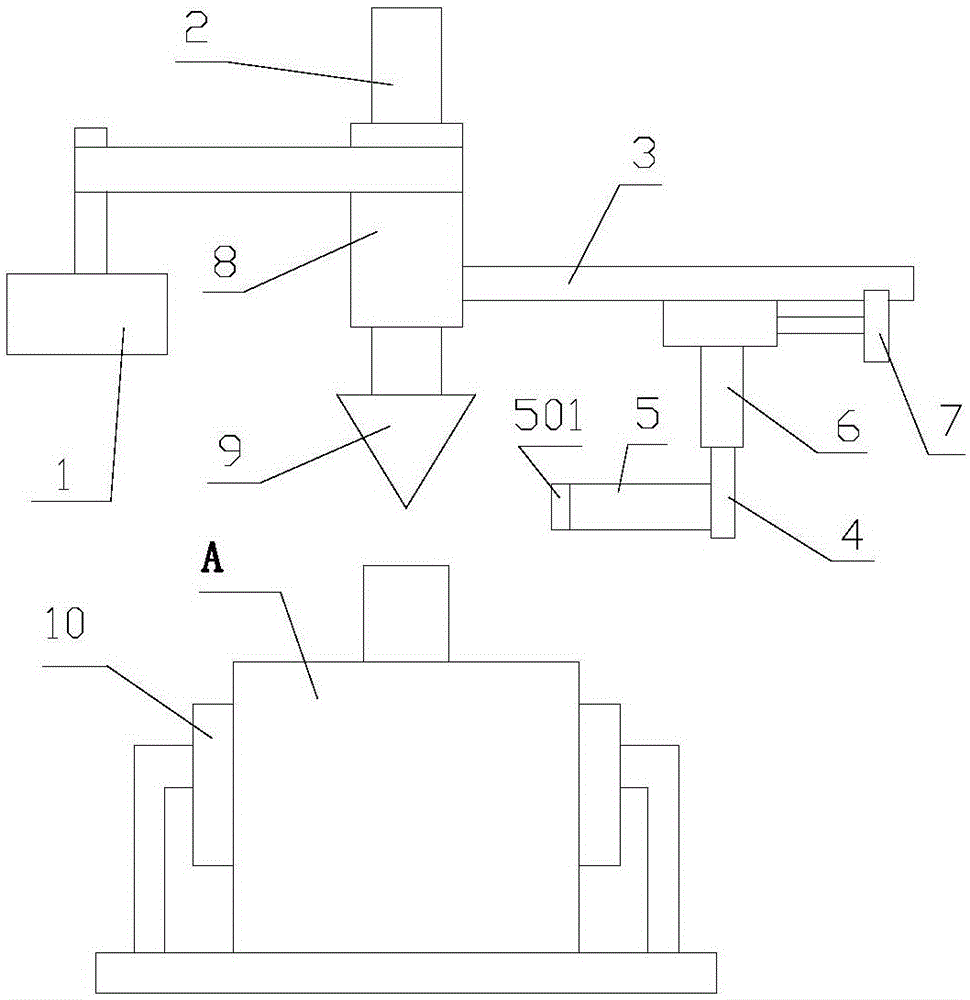

[0028] Embodiment 1, combining figure 1 :

[0029] In this embodiment, the material removal mechanism also includes a sleeve 8, which is sleeved on the support rod 2 and is rotatably connected with the support rod 2;

[0030] The end of the cross bar 3 away from the connecting rod 4 is connected to the support rod 2 through the sleeve 8, and the drive unit 1 is in transmission connection with the sleeve 8, and the drive unit 1 drives the cross bar 3 through the sleeve 8 to support the axial direction of the rod 2. Rotate around the center.

[0031] One end of the support rod 2 near the packaging bottle A is provided with a positioning column 9, the positioning column 9 is conical, and its diameter gradually decreases from the support rod 2 to the direction of the packaging bottle A. coincide. The positioning column 9 can be used to locate packaging bottles A of different diameters from the mouth of the packaging bottle A, so as to ensure the accuracy of material removal, av...

Embodiment 2

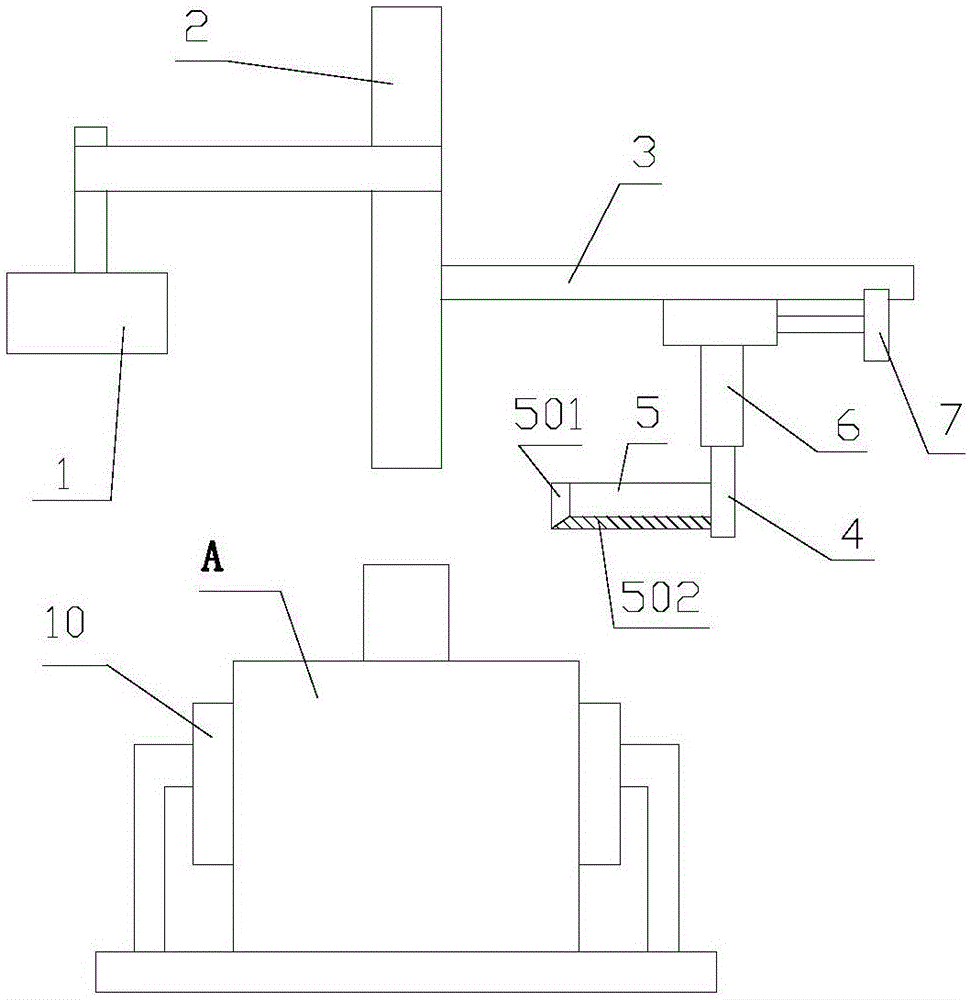

[0032] Example 2, combined with figure 2 :

[0033] In this embodiment, the drive unit 1 drives the support rod 2 to rotate and then drives the cross bar 3 to rotate around the axis of the support rod 2 . The blade 5 includes a second blade 502 , which is perpendicular to the The direction of the axis is extended, and the second blade 502 is located at the side of the blade 5 close to the packaging bottle A. In this embodiment, the blade 5 is horizontally arranged, and the second blade 502 is located at the bottom of the blade 5 . Through the design of the second blade 502, the remaining material and burrs on the end surface of the bottle mouth of the packaging bottle A can be removed in the radial direction, and the use effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com