Accumulated chipping removing device of stir friction spot welding apparatus

A technology of spot welding equipment and friction stirring, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of difficult removal of chip accumulation in the stirring head, and achieve the effect of improving chip removal efficiency and facilitating discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

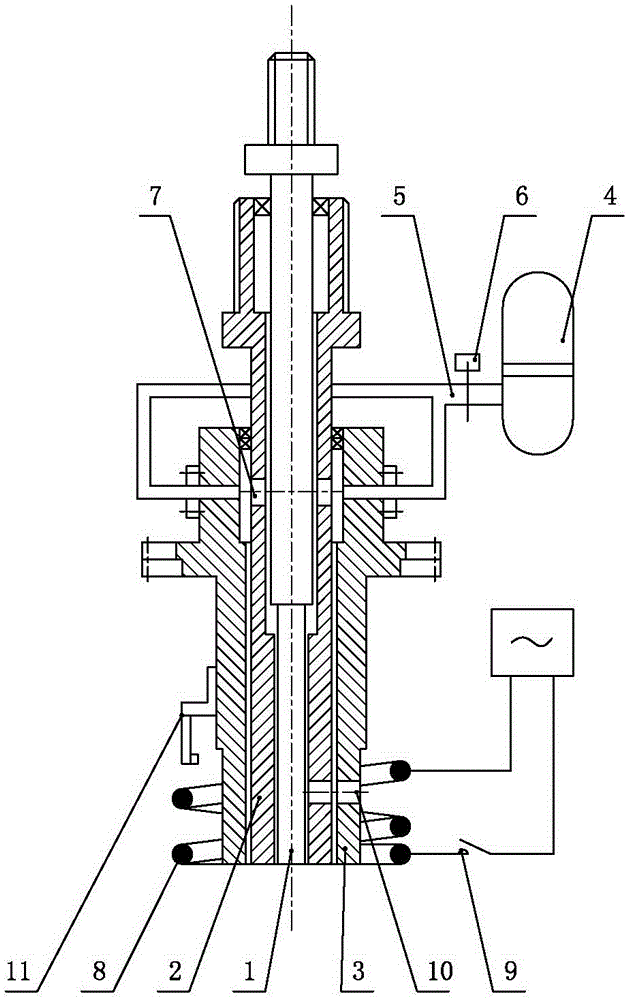

[0016] like figure 1 As shown, it is a structural schematic diagram of the present invention, and the stirring head includes an internal stirring needle 1 , an intermediate sleeve 2 with a clearance fit with the stirring needle 1 , and an outermost jacket 3 with a clearance fit with the sleeve 2 . The high-pressure gas source 4 is connected with a high-pressure pipe 5, and an electromagnetic gas valve 6 is set on the high-pressure pipe 5, and the supply and cut-off of the high-pressure gas source 4 are realized by controlling the electromagnetic valve 6 through the host computer. The end of the high-pressure pipe 5 is divided into two branches, and the two branches are respectively connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com