Floating-type multifunctional BTA deep-hole cutter system based on self-guiding

A tool system, floating technology, applied in drilling accessories, manufacturing tools, drilling/drilling equipment, etc., can solve the bending deformation of the drill pipe system, it is difficult to ensure the hole size, straightness, roundness consistency and accuracy Requirements and other issues to achieve the effect of improving processing quality, enhancing self-guiding function, and coordinating self-guiding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

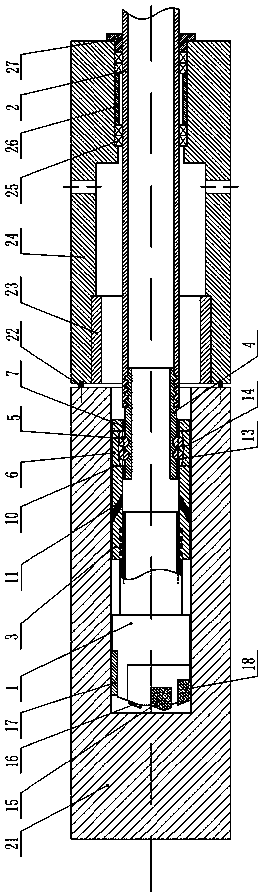

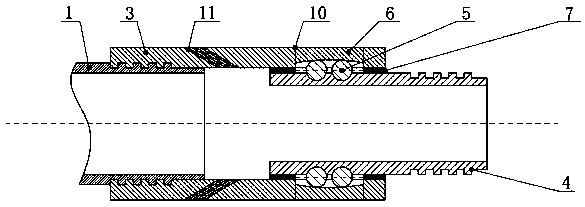

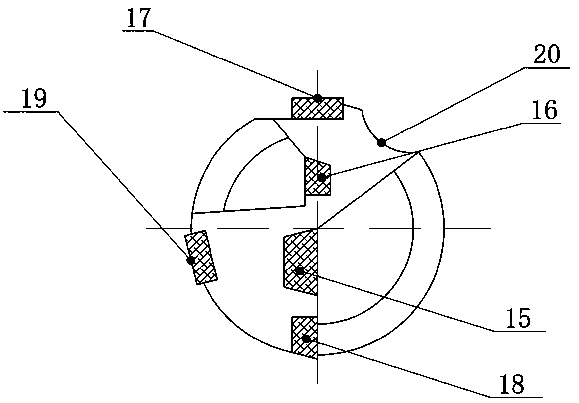

[0028] The present embodiment provides a self-guided floating multifunctional BTA deep hole tool system, including a BTA cutter head 1 and a drill rod 2, which are connected by a floating connection device between the BTA cutter head and the drill rod; the floating connection device includes The cutter head connector 3, the cutter rod connector 4, the ball 5, the upper end cover 6, the rubber ring 7, the damping block 8 and the auxiliary guide strip 9; the front end of the cutter head connector 3 is detachably connected with the BTA cutter head 1, close to The position of the rear end is provided with a plurality of upper end cover installation holes 10 along the circumferential direction, the cutter head connector 3 is provided with multiple sets of jet holes 11 along the circumferential direction, and a plurality of cutting fluid grooves I12 are provided on the outer cylindrical surface along the circumferential direction The jet hole 11 is located before the upper end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com