Annular bidirectional stepping push rod chip removal device

A chip removal device, a step-by-step technology, applied to chip rolling, can solve the problem of low cleaning efficiency of iron chips, and achieve the effects of reducing labor intensity, low energy consumption, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

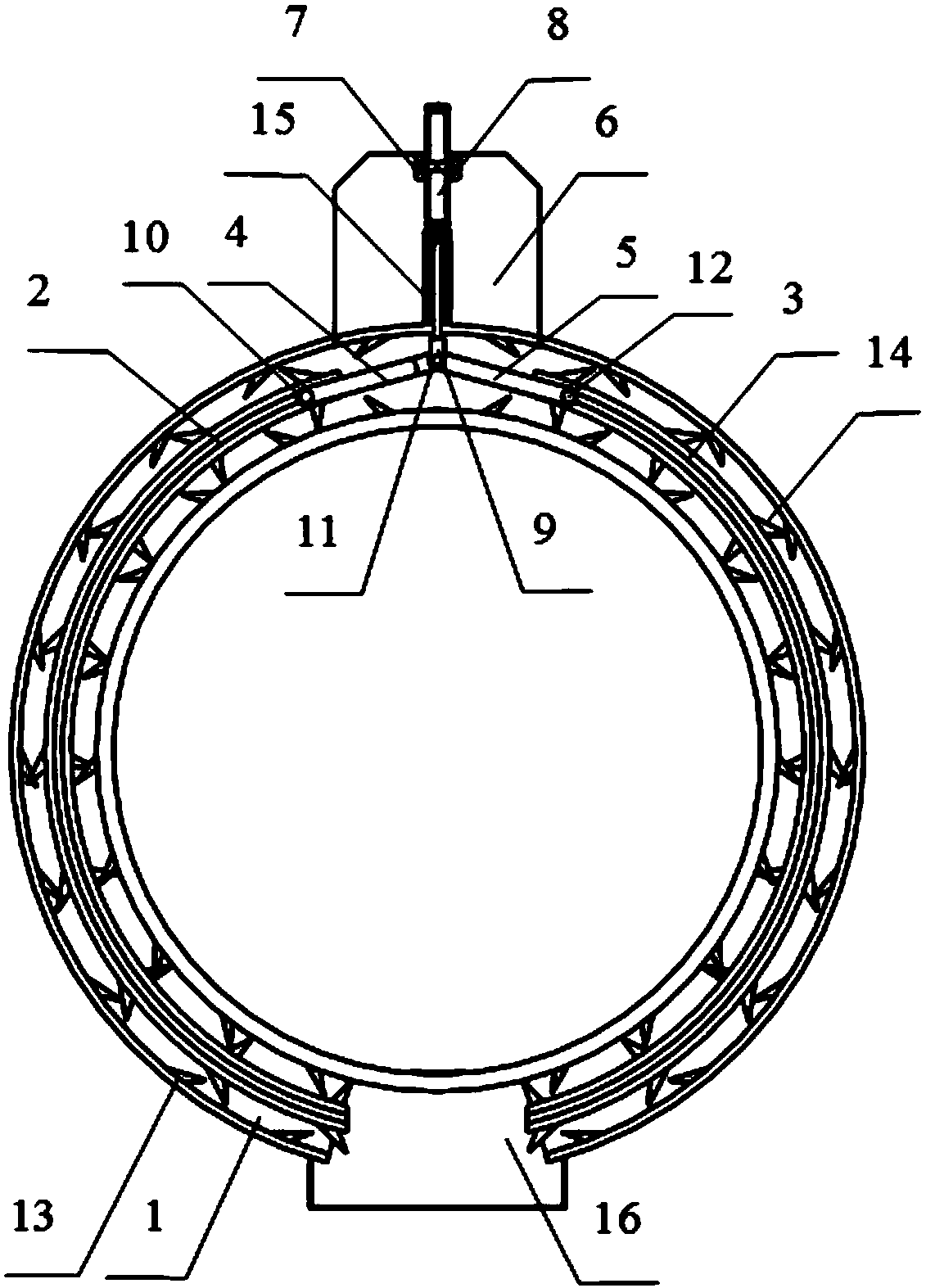

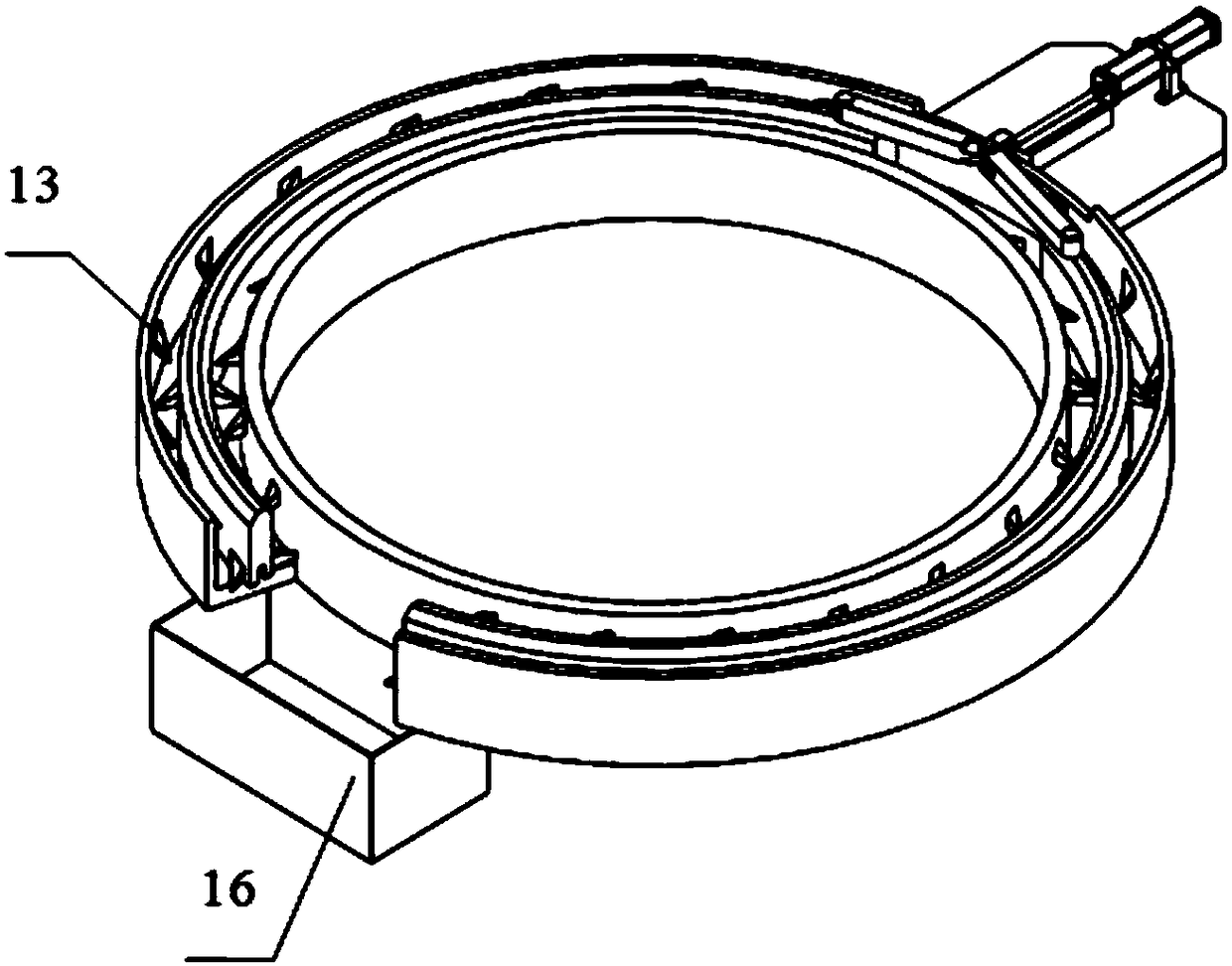

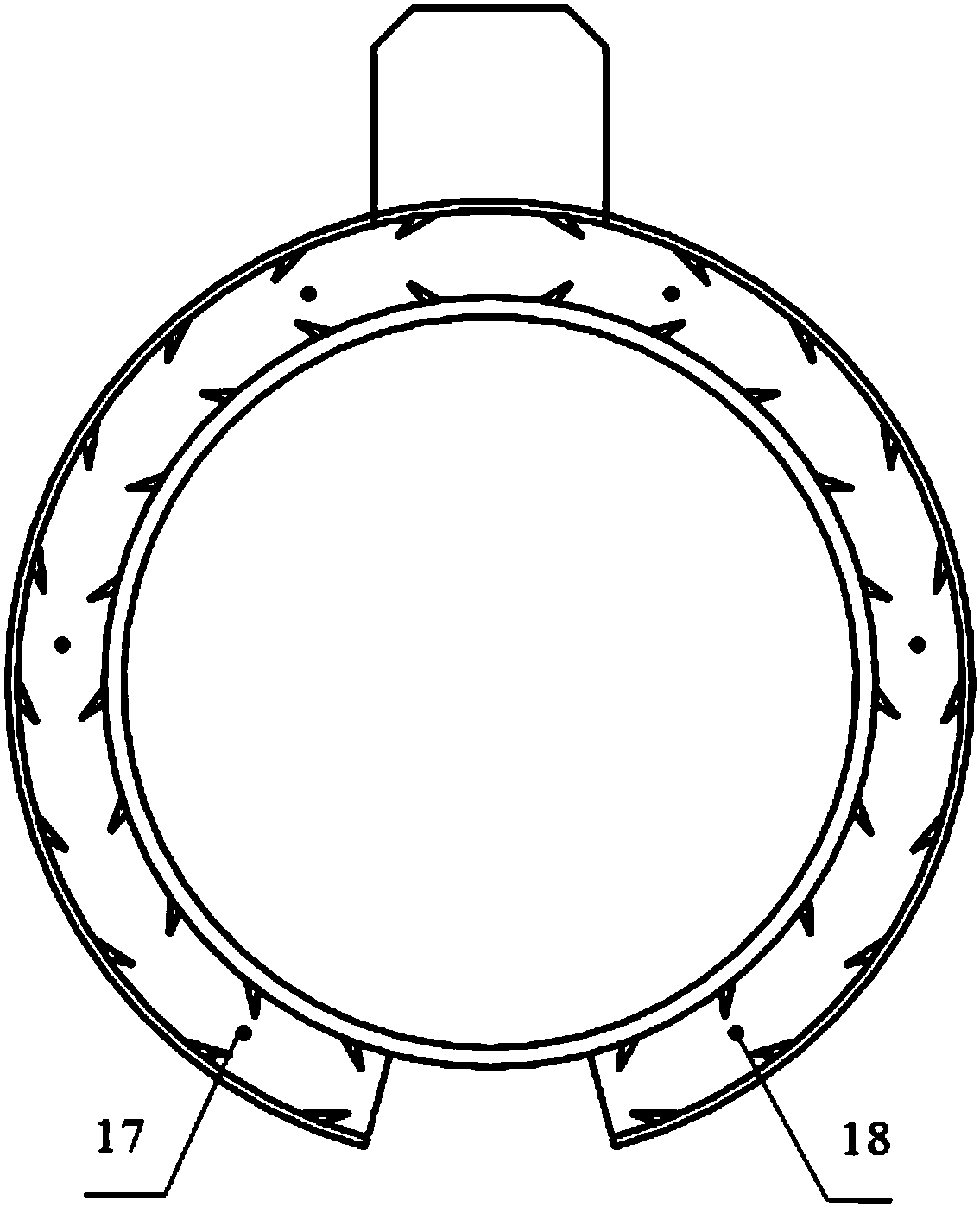

[0019] The patent will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] An annular two-way stepping push rod chip removal device mainly includes an annular groove body 1, an annular push rod 1 2, an annular push rod 2 3, a connecting rod 4, a connecting rod 2 5, a support plate 6, and a support 7. Oil cylinder 8, joint 9, pin one 10, pin two 11, pin three 12, chip retaining structure 13, chip pushing structure 14, guide groove 15, chip receiving bucket 16, guide roller one 17, guide roller two 18.

[0021] Wherein ring-shaped push rod one 2, ring-shaped push rod two 3, connecting rod one 4, connecting rod two 5 are located inside the annular groove body 1, and ring-shaped push rod one 2, ring-shaped push rod two 3, connecting rod one 4, The two ends of the connecting rod 5 have a through hole respectively, which is used to connect with relevant functional parts; one end of the annular tank body 1 is an open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com