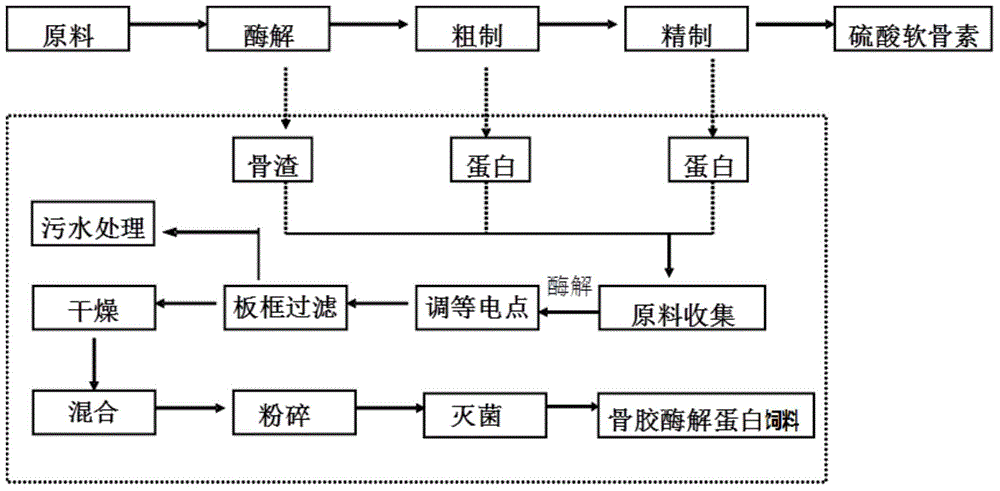

Bone glue enzyme hydrolyzed protein feed processed by residues obtained by extracting chondroitin sulfate and processing method for bone glue enzyme hydrolyzed protein feed

A chondroitin sulfate, processing method technology, applied in animal feed, animal feed, application and other directions, can solve the problems of lack of waste product development process design, low practical value, difficult purification, etc., to achieve stable and unified final quality, improve The effect of digestion and absorption, reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Raw material collection: the filtrate 2 after alcohol precipitation in the above-mentioned chondroitin sulfate extraction example is rectified by a rectification tower to obtain alcohol and protein residues, and the protein residues, the above-mentioned effluent 1 and the eluent 1 and the above-mentioned filter residue 1 are divided into 7: Add the ratio of 1 to the reaction kettle; enzymolysis: adjust the pH value to 5.5, the temperature is 54 ° C, add papain with a mass of 3% of the material, and enzymolysis for 2 hours; adjust the isoelectric point: dissolve the above enzymolysis solution with hydrochloric acid or sulfuric Adjust the pH of the mixed solution to 4; let it stand for stratification; filter: separate the filter residue by plate and frame filtration; dry: vacuum dry the filter residue after filtration, and control the moisture content of the dry material to 5%; mix: mix in a mixer for 0.5h; pulverize : The material is pulverized by a ball mill, and the par...

Embodiment 2

[0037]Raw material collection: the filtrate 2 after alcohol precipitation in the above-mentioned chondroitin sulfate extraction example is rectified by a rectification tower to obtain recovered alcohol and protein residues, and the protein residues, the above-mentioned effluent 1 and the eluent 1 and the above-mentioned filter residue 1 are pressed by 1: Add the ratio of 1 to the reaction kettle; enzymatic hydrolysis: adjust the pH value to 6.0, the temperature is 55 ° C, add papain with 1% of the mass of the material, and enzymolyze for 1.5 hours; adjust the isoelectric point: use hydrochloric acid or sulfuric acid to Adjust the pH of the mixed solution to 4; let it stand for stratification; filter: separate the filter residue by plate and frame filtration; dry: vacuum dry the filter residue after filtration, and control the moisture content of the dry material to 5%; mix: mix in a mixer for 0.5h; Crushing: the material is pulverized by a ball mill, and the particle size is co...

Embodiment 3

[0039] Raw material collection: the filtrate 2 after alcohol precipitation in the above-mentioned chondroitin sulfate extraction example is rectified by a rectification tower to obtain alcohol and protein residues, and the protein residues, the above-mentioned effluent 1 and the eluent 1 and the above-mentioned filter residue 1 are divided into 5: Add the ratio of 1 to the reaction kettle; enzymatic hydrolysis: adjust the pH value to 6.5, the temperature is 56 ° C, add bromelain with a mass of 2% of the material, and enzymolyze for 1 hour; The pH of the mixed liquid is adjusted to 5; stand for stratification; filter: separate the filter residue by plate and frame filtration; dry: vacuum dry the filter residue after filtration, and control the moisture content of the dry material to 5%; mix: mix in a mixer for 0.5h; pulverize : The material is pulverized by a ball mill, and the particle size is controlled to be 80 mesh; Sterilization: Sterilized by irradiation, the irradiation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com