Fungicide for compound oilfield reinjection water, and preparation method therefor

A technology for oil field re-injection of water and fungicides, applied in the fields of botanical equipment and methods, biocides, sterilization/microdynamic water/sewage treatment, etc. problem, to achieve the effect of stable hydrolysis, saving pharmaceutical costs, and good killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

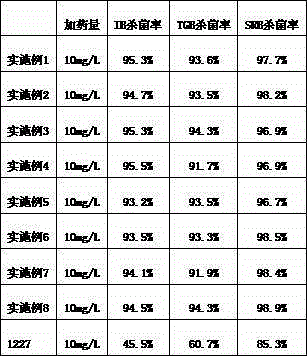

Examples

Embodiment 1

[0014] Weigh 20 g of tetrakis hydroxymethyl phosphorus chloride, 15 g of dibromonitrilopropionamide, 20 g of 50% glutaraldehyde aqueous solution, and 45 g of pure water.

[0015] Add pure water, tetrakishydroxymethylphosphorus chloride, dibromonitrilopropionamide, and 50% glutaraldehyde aqueous solution into the container in sequence, and stir at room temperature for 4 to 5 hours to obtain 100 g of the product.

Embodiment 2

[0017] Weigh 30 g of tetrakis hydroxymethyl phosphorus chloride, 10 g of dibromonitrilopropionamide, 30 g of 50% glutaraldehyde aqueous solution, and 30 g of pure water.

[0018] Add pure water, tetrakishydroxymethylphosphorus chloride, dibromonitrilopropionamide, and 50% glutaraldehyde aqueous solution into the container sequentially in proportion, and stir at room temperature for 4 to 5 hours to obtain 100 g of the product.

Embodiment 3

[0020] Weigh 30 g of tetrakis hydroxymethyl phosphorus chloride, 20 g of dibromonitrilopropionamide, 10 g of 50% glutaraldehyde aqueous solution, and 40 g of pure water.

[0021] Add pure water, tetrakishydroxymethylphosphorus chloride, dibromonitrilopropionamide and butanediamine into the container sequentially in proportion, and stir at room temperature for 4-5 hours to obtain 100 g of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com