Filter and manufacturing method thereof

A technology of filters and metal layers, which is applied in waveguide devices, resonators, circuits, etc., can solve the problems of large size of planar PCB circuits and cannot meet the requirements of wireless communication, and achieve the effect of compact structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the resonant cavity is a U-shaped slot line formed in the metal layer, and the input and output feed lines of the coplanar waveguide are formed in the same metal layer. The structure is compact, easy to integrate in the integrated circuit process, and can Perform strong coupling power supply to achieve wide bandwidth and low insertion loss performance.

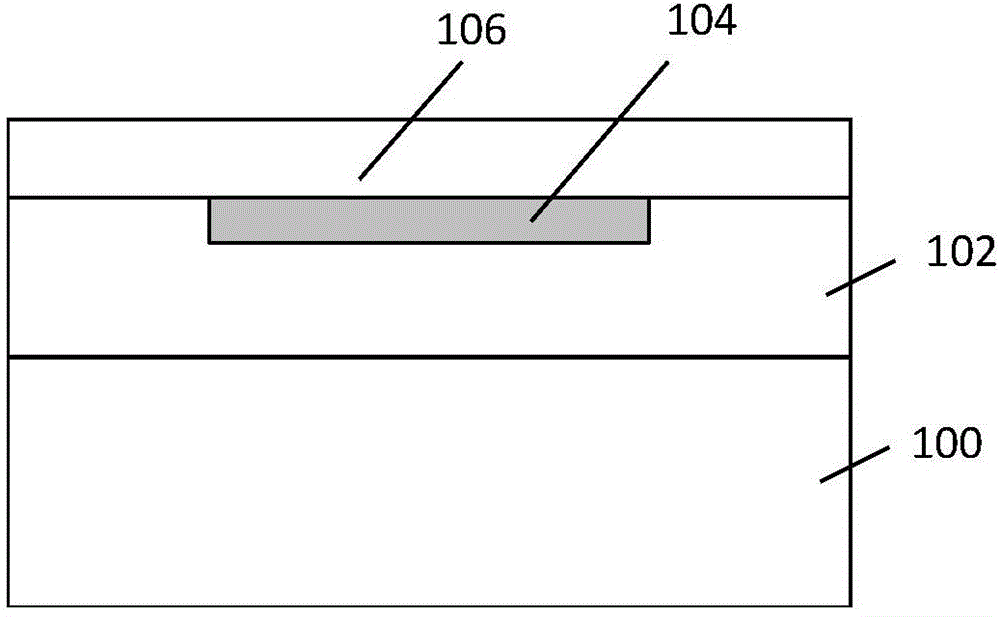

[0039] In this example, refer to figure 1 As shown, the filter includes:

[0040] substrate 100;

[0041] a dielectric layer 102 on the substrate;

[0042] the first metal layer 104 in the dielectric layer; and

[0043] A slot line resonator and input and output feed lines are formed in the first metal layer 104 .

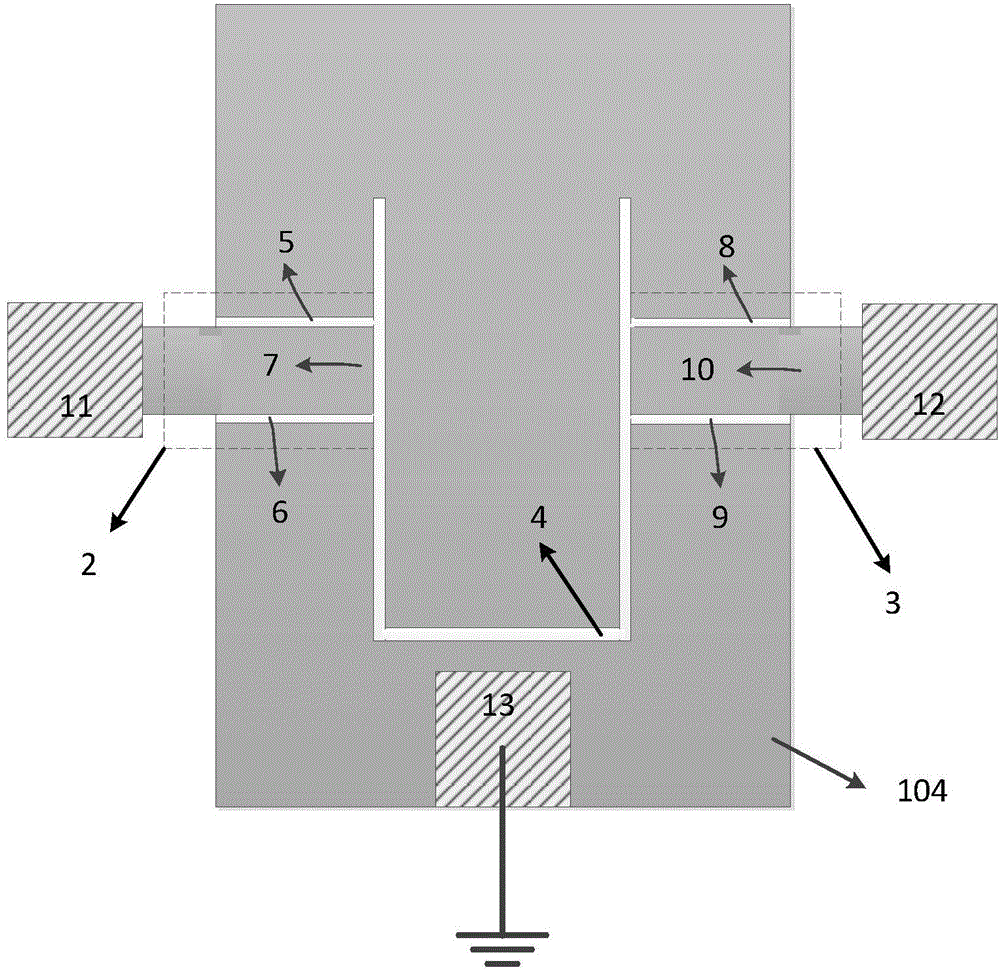

[0044] Such as figure 2 As shown, it is a top view of the first metal layer, and the resonant cavity 4 , the input feeder 2 and the output feeder 3 are formed in the first metal layer 104 .

[0045] In this embodiment, the resonant cavity is a slot line resonator 4 formed in the fi...

Embodiment 2

[0064] In this embodiment, the resonant cavity is a U-shaped slot line formed in a metal layer, and the input and output feed lines of the microstrip line are formed in another metal layer.

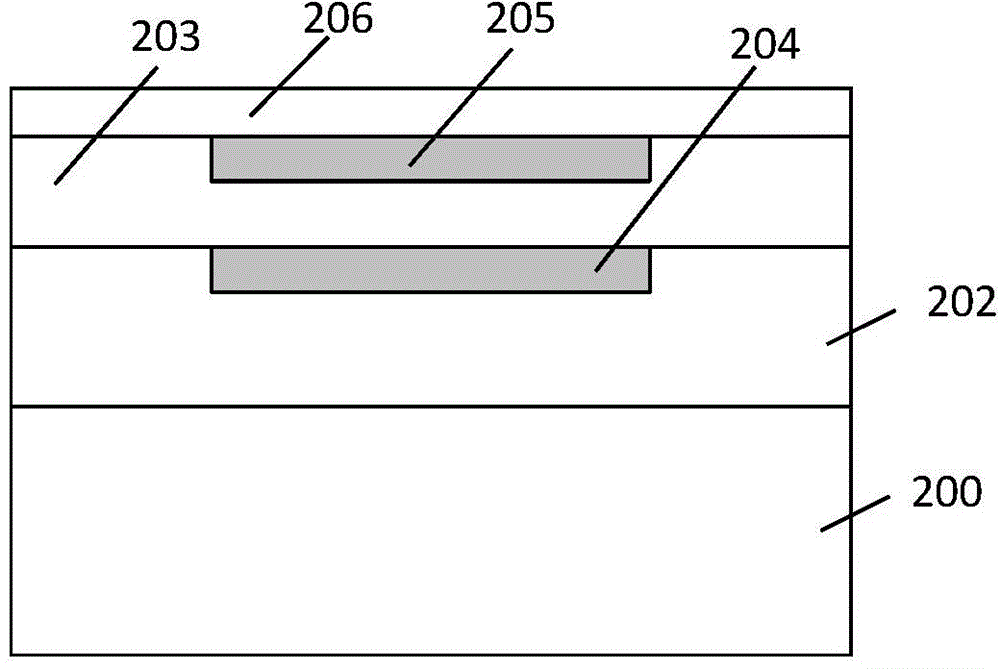

[0065] In this example, refer to image 3 As shown, the filter includes:

[0066] substrate 200;

[0067] The first dielectric layer 202 on the substrate, and the first metal layer 204 in the first dielectric layer 202;

[0068] A second dielectric layer 203 on the first dielectric layer 202, a second metal layer 205 in the second dielectric layer on the first metal layer;

[0069] Wherein, the slot line resonant cavity is formed in the first metal layer 204, and the second metal layer 205 is the input feed line and the output feed line of the microstrip transmission line.

[0070] Such as Figure 4 As shown, it is a top view of the first metal layer, which is the same as the resonant cavity structure in Embodiment 1. A slot line resonator 4 is formed in the first metal layer 104, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com