Zhengtian pill mixing process end point determination method

A technology of mixing process and measurement method, which is applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of unstable quality, time-consuming and labor-intensive, and no unified judgment standard, and achieve stable product quality and improve product quality. Production efficiency, the effect of improving the level of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. stratified sampling

[0027] The setting of sampling points during the mixing process of Zhengtian pills includes: extending into the left and right sides of the feed inlet, setting 7 sampling points on the material surface, material middle layer and material bottom respectively, a total of 14 sampling points, see figure 1 . Sampling time point settings include: mixing 0min (mixing not started), mixing 10min, mixing 20min and mixing 30min (mixing stopped).

[0028] 2. Sample near-infrared spectrum collection

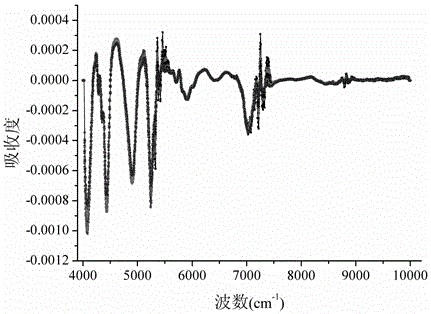

[0029] Take the sample powder during the mixing process in the sample tank, keep the powder surface flush with the sample tank surface, use a diffuse reflection integrating sphere to collect near-infrared spectra, use air as a reference, scan times 32, resolution 8cm -1 , the scanning spectrum range is 4000~10000cm -1 ; Each sample was collected 3 times, and the average spectrum was saved, and the data saving format was 1 / logR, see figure 2 .

[0030] 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com