Construction method of steel-concrete composite pile in water for cast-in-place support of concrete ballasted box girder of cable-stayed bridge

A technology of concrete ballast and box girder cast-in-place, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of high safety risk of flood crossing, high construction cost, and difficult dismantling, so as to improve the safety of supports, Simple set-up and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

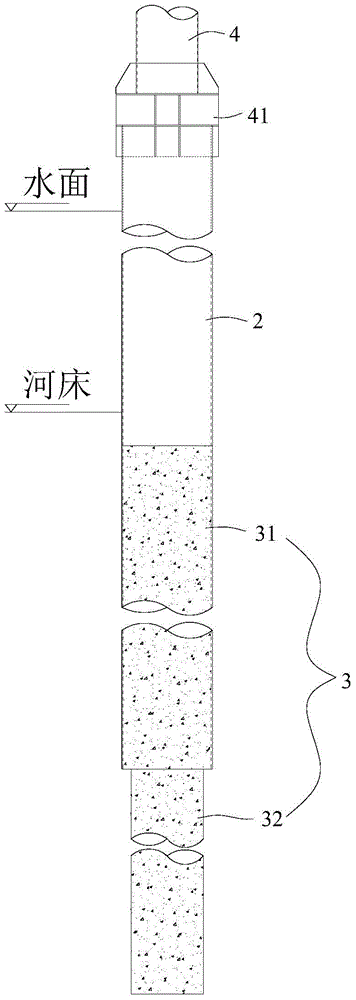

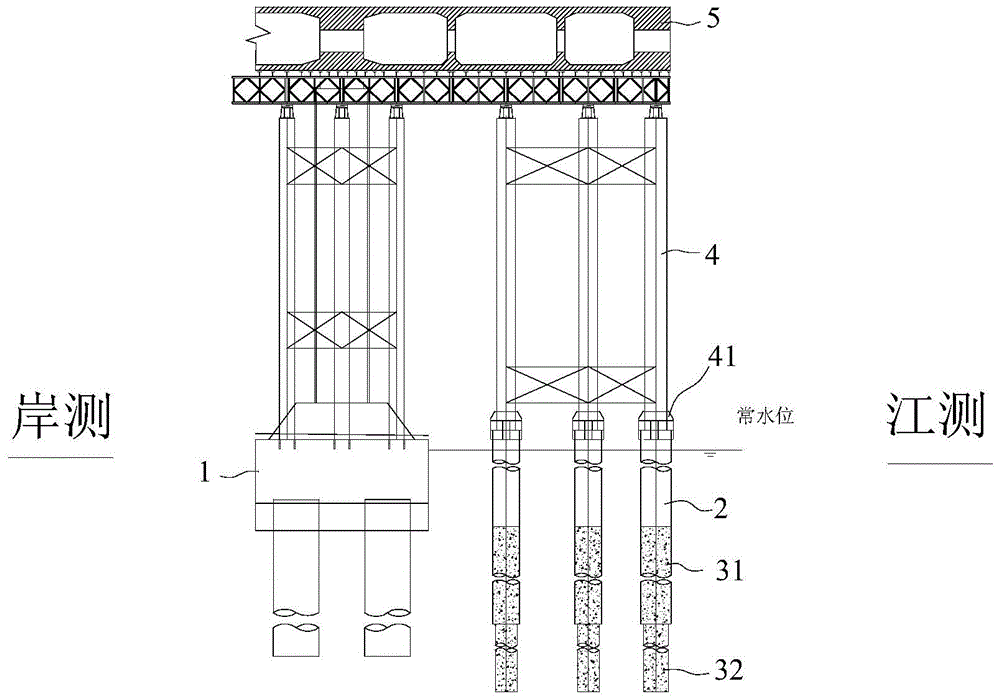

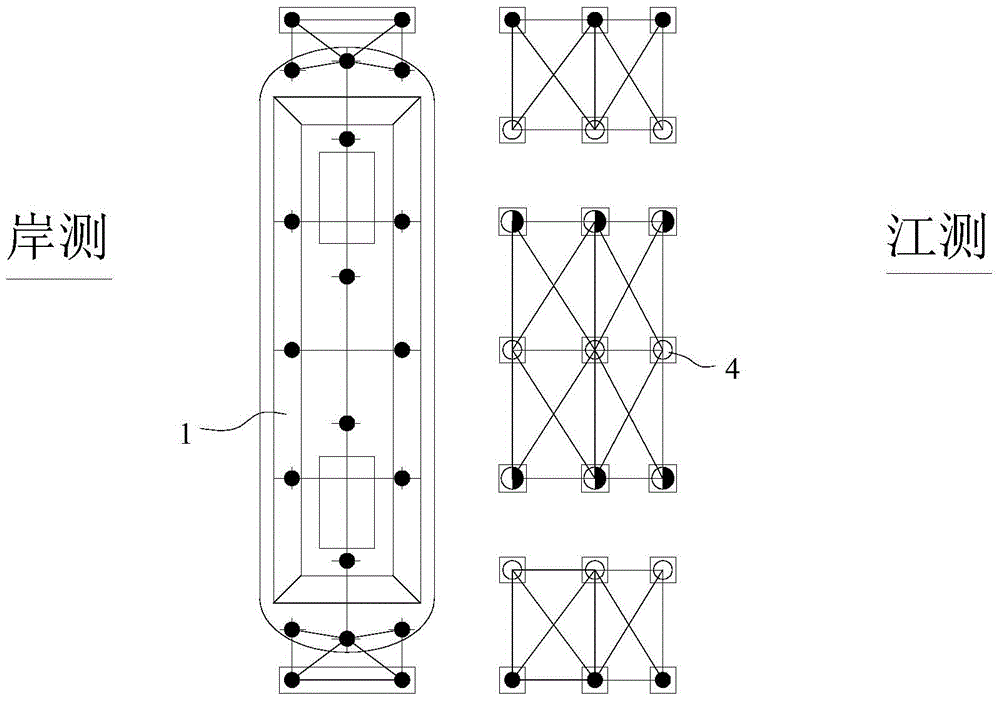

[0032] refer to Figure 1 to Figure 3 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 2 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0033] The invention provides a construction method of steel-concrete composite piles in water for cast-in-place supports of concrete ballasted box girders of cable-stayed bridges, comprising the following steps:

[0034] S10. Insert a number of steel casings on the side of the auxiliary pier of the cable-stayed bridge away from the shore. When inserting, a small crawler crane stands on the top surface of the auxiliary pier cap 1 and hangs a small vibrating hammer in the direction of the mid-span to insert s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com