Manufacturing method for steel wire inhaul cable with polyurea protective coating

A technology of protective coating and manufacturing method, which is applied in the field of manufacturing steel wire cables with polyurea protective coating, and can solve the problems of reducing the strength level of steel wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

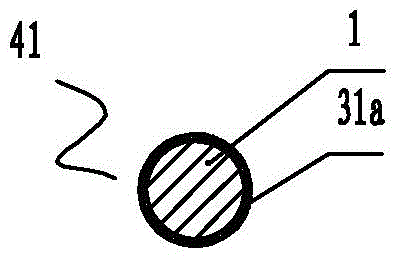

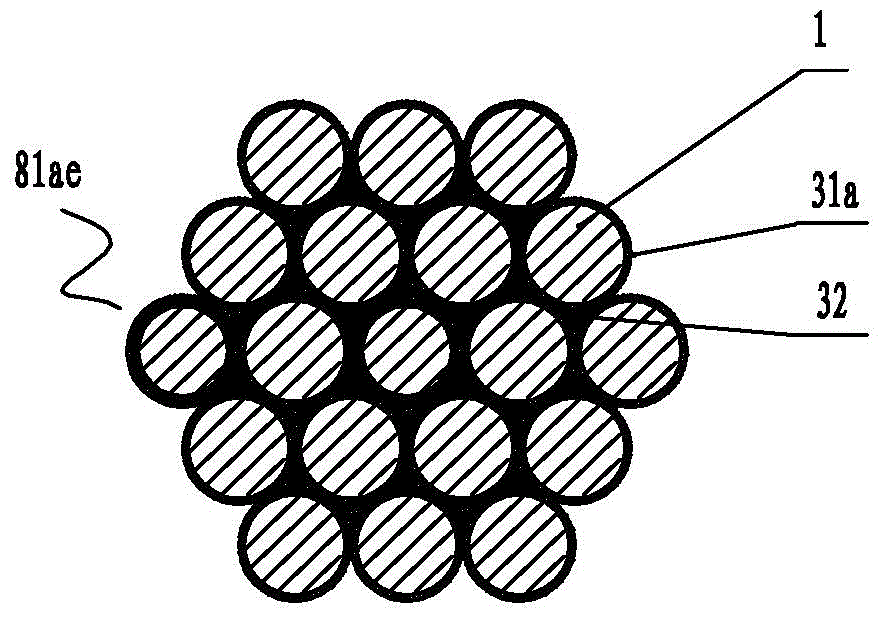

Embodiment 1

[0171] A method for manufacturing a steel wire cable with a polyurea protective coating, which is to firstly produce a steel wire with a polyurea protective coating, and then pass the steel wire with a polyurea protective coating through a polyurea material filling process through wire separation, and then fill the steel wire with a polyurea protective coating. Each steel wire with polyurea protective coating is filled with polyurea material 32, and then undergoes agglomeration step to form a steel wire assembly composed of n steel wires with polyurea protective coating, forming a steel wire with polyurea protective coating Steel wire cables Iae and IIae with polyurea protective coating composed of and filled with polyurea material 32 between the steel wires with polyurea protective coating;

[0172] Its specific steps include: A, making steel wire with polyurea protective coating; B, splitting C, polyurea material filling process: filling polyurea material 32 between the steel...

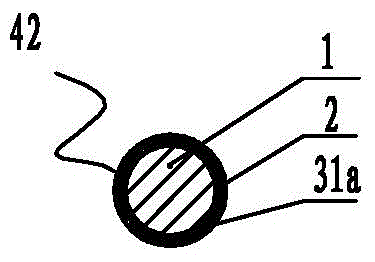

Embodiment 2

[0203] Steel wires with polyurea protective coating are filled with polyurea materials between the steel wires with polyurea protective coating inside the steel wire assembly. There is a polyurea protective coating II on the periphery of the steel wire assembly with polyurea protective coating. The production method of steel wire cable with protective coating:

[0204] A steel wire assembly made of n steel wires with a polyurea protective coating made in Example 1, and a steel wire assembly with a polyurea protective coating filled with polyurea material between each steel wire with a polyurea protective coating Steel cables Iae and IIae go through E: polyurea material coating process II, that is, through one of the following methods:

[0205] ① Extrusion coating: polyurea material hot-extruded by steel wire cable Ⅰae or Ⅱae through extrusion equipment;

[0206] ② Spraying: heat and pressurize the equipment, the raw materials are mixed at the nozzle, and then the polyurea mat...

Embodiment 3

[0225]The steel wire assembly of the steel wire cable with a polyurea protective coating has a wrapping tape outside the body, and the outer layer of the wrapping tape is coated with a polyurea protective coating. The production of a steel wire cable with a polyurea protective coating method:

[0226] The steel wire cables Iae and IIae with a polyurea protective coating produced in Example 1 and the steel wire cables Ibe and IIbe with a polyurea protective coating produced in Example 2 were subjected to F: wrapping forming step, wrapped The upper wrapping tape 5 constitutes a steel wire cable Iaeo, IIaeo, Ibeo or IIbeo with a polyurea protective coating (see Figure 4-1 to Figure 4-4 ).

[0227] Then wrap the steel wire assembly with a polyurea protective coating steel wire cable Ⅰaeo, Ⅱaeo, Ⅰbeo or Ⅱbeo with a wrapping tape, and then go through G: polyurea material coating process III, that is, through one of the following methods:

[0228] ①Extrusion coating: the polyurea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com