Steel wire stayed cable filled or coated with polyurea protection materials

A protective material and steel wire technology, which is applied in the field of cables, can solve the problems of hydrogen embrittlement, reduce the strength level of steel wires, etc., and achieve the effect of improving anti-corrosion and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] A steel wire cable filled with polyurea material in the middle of n steel wires or coated with polyurea protective material:

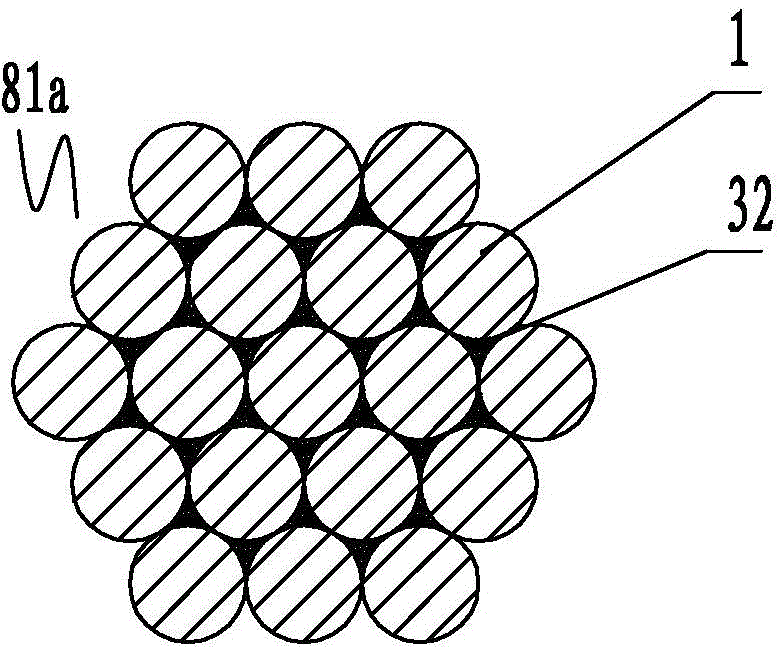

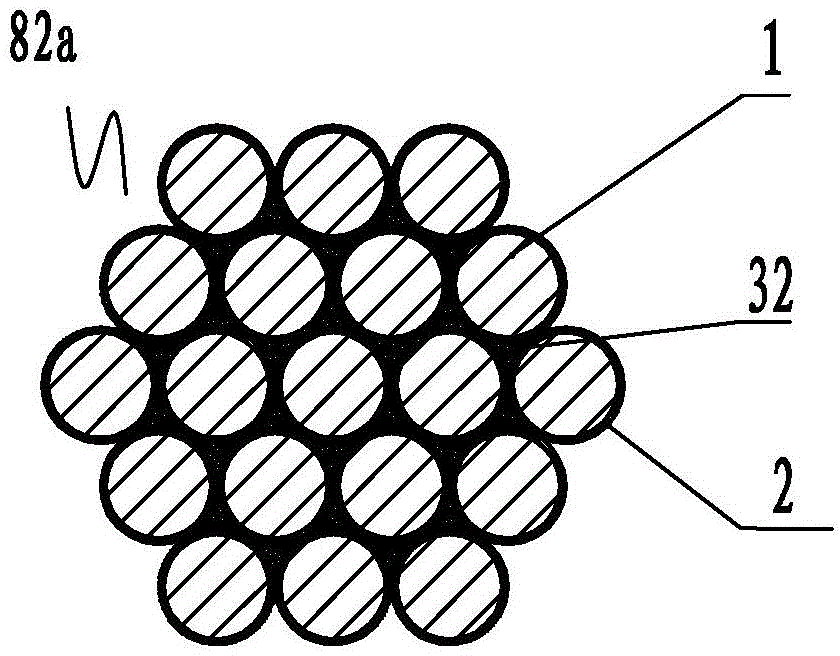

[0119] Such as Figure 1-1~Figure 1-2 , the steel wire cable filled with polyurea material in the middle or coated with polyurea protective material includes a steel wire assembly composed of 19 steel wires, and the steel wires are either smooth steel wires or steel wires on the outer periphery of the smooth steel wire 1 Anti-corrosion steel wire with epoxy coating, galvanized coating, plastic coating, anti-corrosion grease coating, oily wax or metal coating, surface-attached coating or coating 2, between each smooth steel wire in the middle of 19 steel wires Gap filled with polyurea material 32 constitutes the steel wire cable Ia of filling or being coated with polyurea protective material of the present invention (referring to Picture 1-1 ); or the gap between each anti-corrosion steel wire in the middle part of 19 steel wires is filled with...

Embodiment 2

[0124] A steel wire cable filled or coated with a polyurea protective material composed of a polyurea protective coating I coated on the outermost layer of the steel wire assembly:

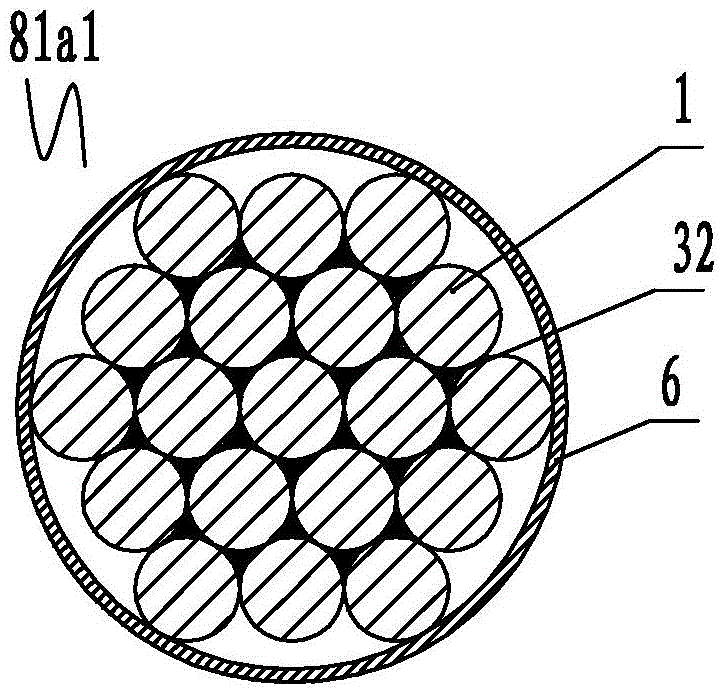

[0125] Such as diagram 2-1 , Figure 2-2 As shown, the outer circumference of the steel wire assembly of steel wire cables Ia and IIa filled with polyurea material or coated with polyurea protective material in the middle of the first embodiment is coated with a layer of polyurea protective coating respectively. Layer I31a, thereby constituting the steel wire cable Ib filled or coated with polyurea protective material (see diagram 2-1 ) and steel wire cables IIb filled or coated with polyurea protective material (see Figure 2-2 );

[0126] As a change in the embodiment of the present invention, the steel wire cables Ib and IIb filled or coated with polyurea protective material have a single-layer HDPE sleeve 6 or have an inner HDPE sleeve 6 and an outer layer The double-layer HDPE sleeve co...

Embodiment 3

[0129] The outer layer of the wrapping tape is coated with a layer of polyurea protective coating Ⅱb, and the steel wire cable is filled or coated with polyurea protective material:

[0130] Such as Figure 3-1 , Figure 3-2As shown, a wrapping tape 5 is also wrapped around the outer circumference of the steel wire assembly of a steel wire cable Ia, IIa filled with polyurea material or coated with polyurea protective material in the middle part described in Embodiment 1, forming Steel wire cables Ⅰa0 and Ⅱa0 filled or coated with polyurea protective material; then the outer layer of wrapping tape 5 of steel wire cable Ⅰa0 and Ⅱa0 filled or coated with polyurea protective material is coated with a layer of polyurea protective coating Layer II31b, constituting steel wire cables Ia0c, IIa0c filled or coated with polyurea protective material (see Figure 3-5 , Figure 3-6 );

[0131] Such as Figure 3-3 , Figure 3-4 As shown, the outermost layer of the steel wire assembly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com