A preparation method of hydrophobic/super-hydrophobic protein coatings

A superhydrophobic, protein technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of low production efficiency, poor mechanical properties of hydrophobic/superhydrophobic protein coatings, and high equipment requirements, and achieves improved preparation speed, bioavailable. Strong degradability and biocompatibility, good mechanical flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Whether in fundamental research or in industry, superhydrophobic surfaces (SHS) have attracted increasing attention due to their potential applications as self-cleaning surfaces, such as solar cells, automobile windshields, and traffic lights. The SHS surface is also capable of anti-fouling, anti-biofouling, anti-stick and water-repellent properties. Despite numerous successful biomimetic studies to achieve superhydrophobic surfaces, only a few have addressed their potential biomaterial applications. In view of this, the embodiment of the present invention provides a method for preparing a hydrophobic / superhydrophobic protein coating, comprising the following steps:

[0023] S01. Weighing zein and dissolving it in an alcohol-water solution to form a zein solution and then performing mixing treatment, the solubility of the zein solution is 50-400 mg / ml;

[0024] S02. The zein solution is placed in a syringe of an electrospinning device to prepare a hydrophobic / superhydr...

Embodiment 1

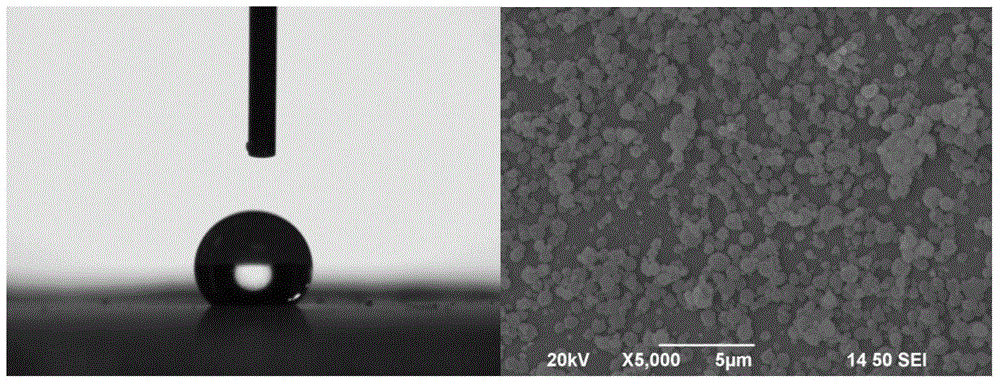

[0035] Under normal temperature and pressure (15-35°C, 1 standard atmospheric pressure), weigh 0.5g of zein, dissolve it in 10ml of 80% (v / v) ethanol-water, make a 50mg / ml solution, and ultrasonicate for 10min. until the solution is homogeneous and transparent. The configured solution was injected into the syringe of the electrospinning equipment, the spinning voltage was set to 18kV, the propulsion speed of the spinning solution was 0.2ml / h, and the distance from the spinning needle to the receiving plate was 25cm. Films were prepared by electrospinning equipment. The prepared zein hydrophobic coating has a water contact angle of 138.2°, and its water contact angle and SEM electron micrograph are as attached figure 1 shown.

Embodiment 2

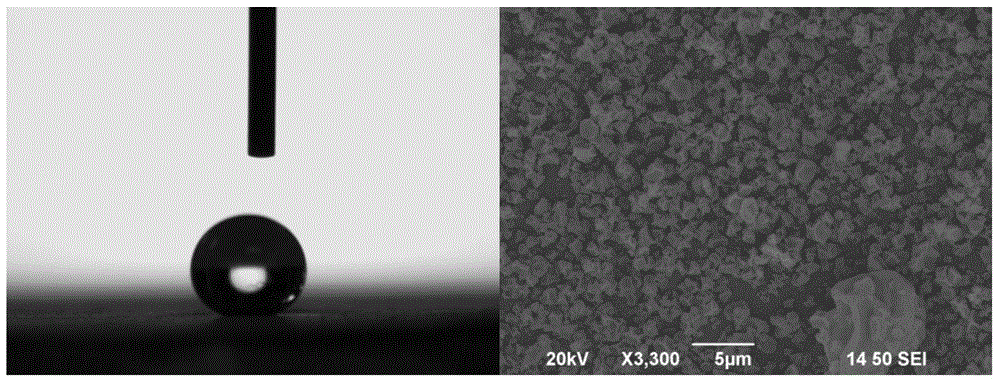

[0037] Under normal temperature and pressure (15-35°C, 1 standard atmospheric pressure), weigh 1.0 g of zein, dissolve it in 10 ml of 80% (v / v) ethanol-water, and prepare a 100 mg / ml solution, and ultrasonicate for 10 min. until the solution is homogeneous and transparent. The configured solution was injected into the syringe of the electrospinning equipment, the spinning voltage was set to 18kV, the propulsion speed of the spinning solution was 0.2ml / h, and the distance from the spinning needle to the receiving plate was 25cm. Films were prepared by electrospinning equipment. The prepared zein superhydrophobic coating has a water contact angle of 153.6°, and its water contact angle and SEM electron microscope pictures are shown in the attached figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com