Method for preparing layered tin coatings in electrolytic deposition manner

A tin coating and electrodeposition technology, which is applied in the field of layered tin coating preparation by electrodeposition, achieves the effects of simple plating solution composition, improved cycle performance, and less deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific Embodiment 1: In this embodiment, a method for preparing a layered tin coating by electrodeposition is as follows: alkaline degreasing, water washing, pickling, and water washing of the plated parts, and drying to obtain the electroplated cathode, using elemental tin as the electroplated cathode Anode; the current density of electroplating is 2~5A / dm 2 , the electroplating temperature is 10-35°C, the electroplating time is 3-9min, and the layered tin coating is obtained; the plating solution contains stannous sulfate, concentrated sulfuric acid, gelatin, additives and ascorbic acid, and the final concentration of stannous sulfate in the plating solution is 35-45g / L, the final concentration of concentrated sulfuric acid is 180-182g / L, the final concentration of gelatin is 0.2-1.0g / L, the final concentration of additives is 0.2-1.6mL / L, and the final concentration of ascorbic acid is 0.3-0.5 g / L.

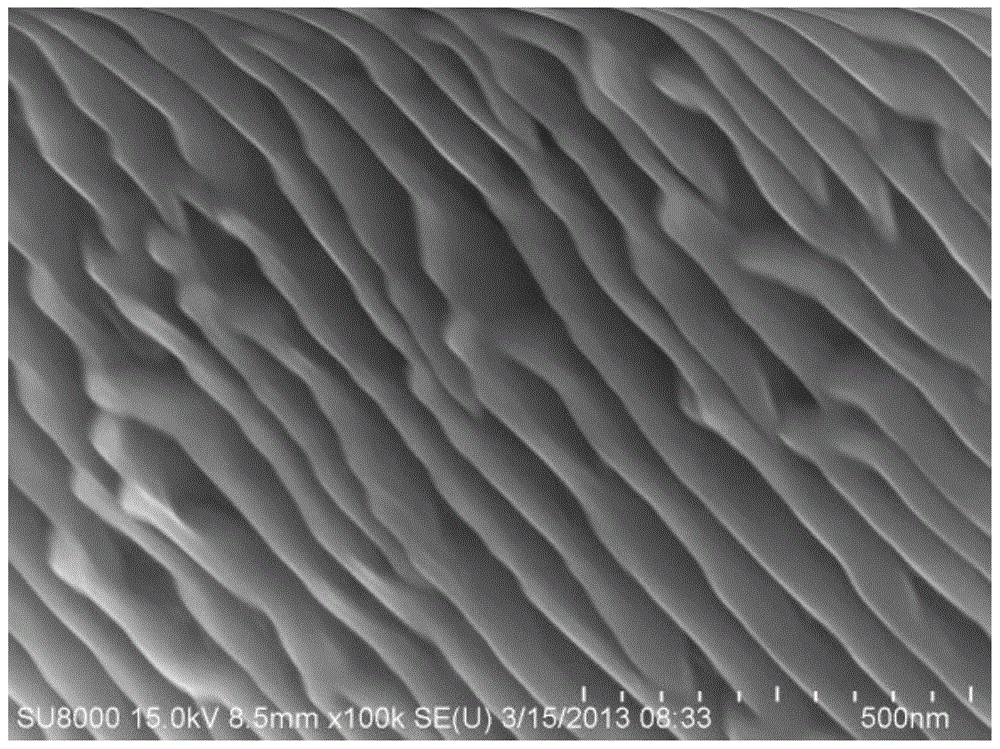

[0010] In this embodiment, the tin coating with a layered struct...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that an aqueous solution with a mass concentration of 20% HCl is used for pickling. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the final concentration of stannous sulfate in the plating solution is 40 g / L. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com