Method for controlling no soft strip at end part of roller body of large forged steel support roller after quenching

A backup roller and control roller technology, which is applied in the direction of heat treatment process control, manufacturing tools, furnace types, etc., can solve the problems of large wear, reduced service life of backup rollers, and large load, and achieve the effect of good hardness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

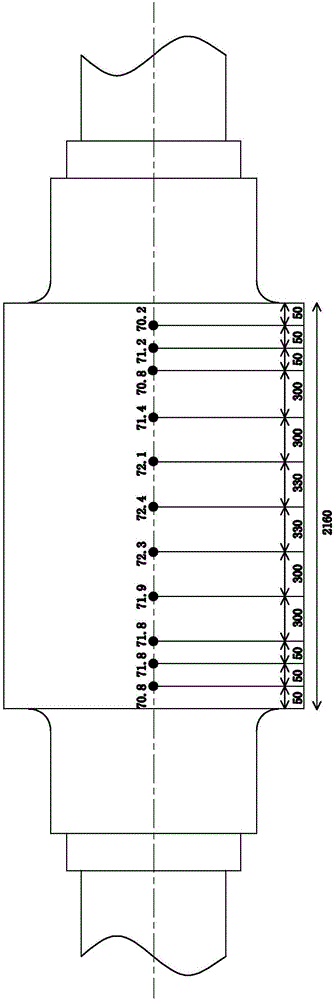

[0014] Taking a large forged steel backup roll with a specification of Φ1630mm×2050mm×5385mm as an example, the method of controlling the large forged steel backup roll without a soft band at the end of the roll body after quenching in this embodiment includes:

[0015] ① During the semi-finishing process, the length of the roll body of the large forged steel support roll is designed to be 2160mm, that is, both sides of the roll body are lengthened by 55mm, so that even if there is a soft band in a small area at the end of the roll body after quenching, This soft band can be removed by turning.

[0016] ②During the heating process, control the temperature uniformity of the surface of the roll body within ±10°C to ensure the uniformity of the final hardness.

[0017] ③After heating and before spray cooling, pre-cool for 10 minutes, and control the temperature difference between the two ends of the roll body and the middle of the roll body to be ≤20°C.

[0018] ④Use the water m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com