125 DEG C irradiation cross-linking low-smoke halogen-free flame-retardant polyolefin cable material

A polyolefin cable material and irradiation technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of difficulty in pelletizing production, increase in screw torque, difficulty in insulation extrusion, etc. The effect of excellent heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A 125°C irradiation cross-linked low-smoke halogen-free flame-retardant polyolefin cable material, comprising the following formula by weight: 60 parts of EVA, 40 parts of HDPE, 45 parts of aluminum hydroxide, 45 parts of magnesium hydroxide, and 5 parts of calcium-zinc composite stabilizer , 10 parts of softening agent, 5 parts of flame retardant, 10 parts of compatibilizer, 11 parts of antioxidant OSP, 0.5 parts of lubricant, 4 parts of crosslinking agent, and the compatibilizer is maleic anhydride grafted PE.

Embodiment 2

[0018] A 125°C irradiation cross-linked low-smoke halogen-free flame-retardant polyolefin cable material, including the following weight ratio formula: 65 parts of EVA, 45 parts of HDPE, 50 parts of aluminum hydroxide, 50 parts of magnesium hydroxide, and 8 parts of calcium-zinc composite stabilizer , 12 parts of softening agent, 8 parts of flame retardant, 15 parts of compatibilizer, 11.2 parts of antioxidant OSP, 0.8 parts of lubricant, 5 parts of crosslinking agent, and the compatibilizer is maleic anhydride grafted PE.

Embodiment 3

[0020] A 125°C irradiation cross-linked low-smoke halogen-free flame-retardant polyolefin cable material, comprising the following formula by weight: 90 parts of EVA, 60 parts of HDPE, 60 parts of aluminum hydroxide, 60 parts of magnesium hydroxide, and 10 parts of calcium-zinc composite stabilizer , 15 parts of softening agent, 10 parts of flame retardant, 18 parts of compatibilizer, 11.5 parts of antioxidant OSP, 1 part of lubricant, 6 parts of crosslinking agent, and the compatibilizer is maleic anhydride grafted PE.

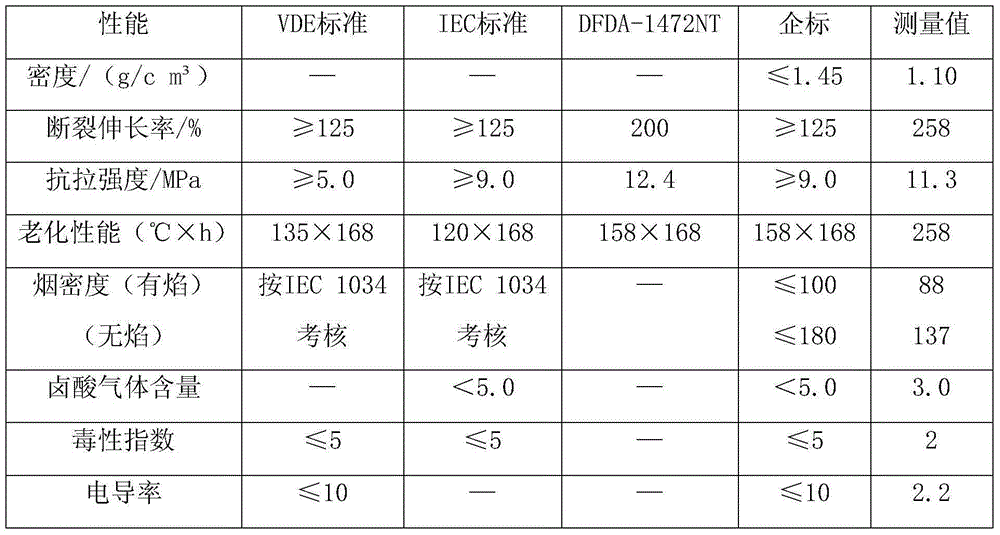

[0021] After testing, all the performances of the product meet the standards. The test results are compared with VDE standard, IEC standard and United Carbide product DFDA21472NT, as shown in Table 1.

[0022] Table 1:

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com