Preparing method for anion intercalation modified hydrotalcite, product and application in PVC hard products

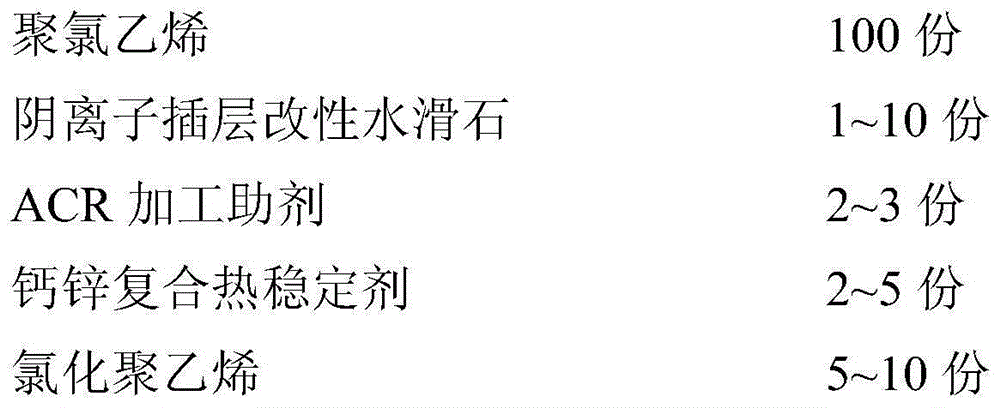

An anionic intercalation and modified water technology, which is applied to the application of anionic intercalation modified hydrotalcite in heat-resistant and smoke-suppressed rigid polyvinyl chloride products, and the field of anionic intercalation modified hydrotalcite and its preparation. Solve problems such as hazards and large quantities, and achieve the effects of reducing degradation, suppressing smoke, and having good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

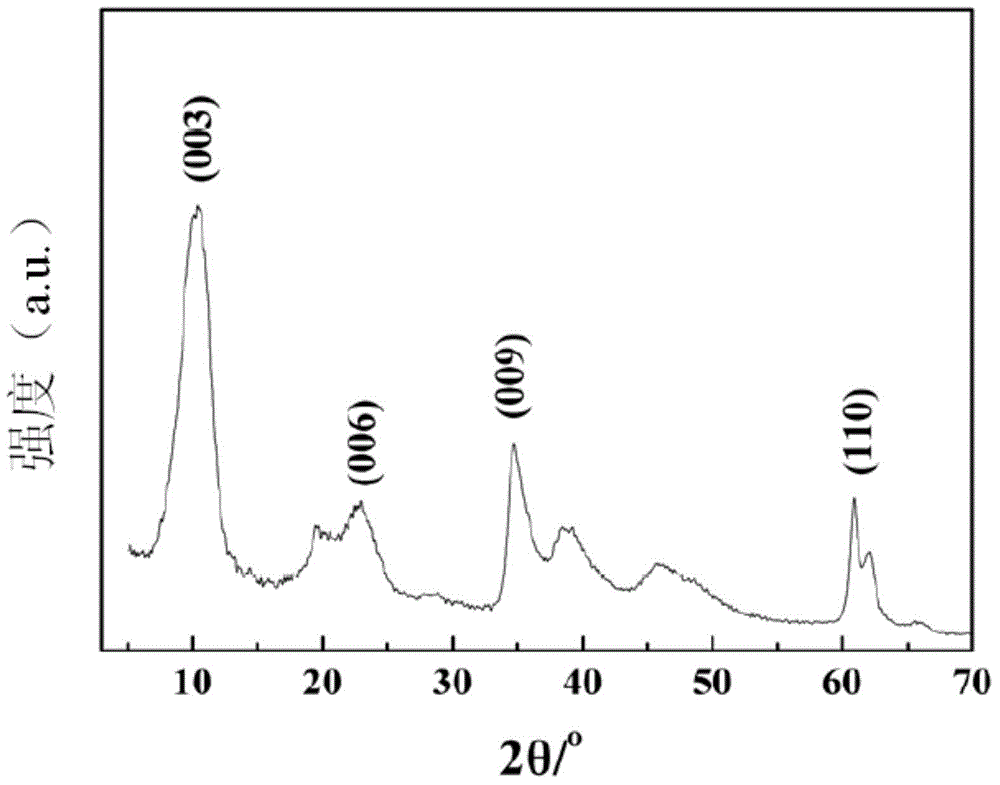

[0031] The preparation of embodiment 1 anion intercalation modified hydrotalcite

[0032] Dissolve 0.045mol of barbituric acid in 200mL of deionized water, and then add it into a 500mL three-necked flask as the bottom liquid, and connect two 100mL constant-pressure dropping funnels to the three-necked flask. Dissolve 0.03 mol of magnesium nitrate and 0.015 mol of aluminum nitrate in 100 mL of deionized water, then add them to the dropping funnel, and add 1 mol / L sodium hydroxide solution to another dropping funnel. Insert the pH meter into the three-necked flask, turn on the magnetic stirring, and the stirring rate is 120rpm. First slowly add sodium hydroxide solution dropwise to convert barbituric acid into barbiturate ions, adjust the pH value of the bottom liquid to 10, then add dropwise the mixed solution of magnesium nitrate and aluminum nitrate and sodium hydroxide solution at the same time, The pH value was controlled at 10±0.1. After the mixed solution of magnesium n...

Embodiment 2~8

[0034] The method of Example 1 was used to prepare barbituric acid intercalation modified hydrotalcite, the difference was that the type and amount of magnesium salt, aluminum salt and barbituric acid were changed, the amount of which is shown in Table 1.

[0035] Table 1

[0036]

[0037]

Embodiment 9~12

[0039] The method of Example 1 was used to prepare cyanuric acid intercalated modified hydrotalcite, except that barbituric acid was replaced by different amounts of cyanuric acid, as shown in Table 2.

[0040] Table 2

[0041]

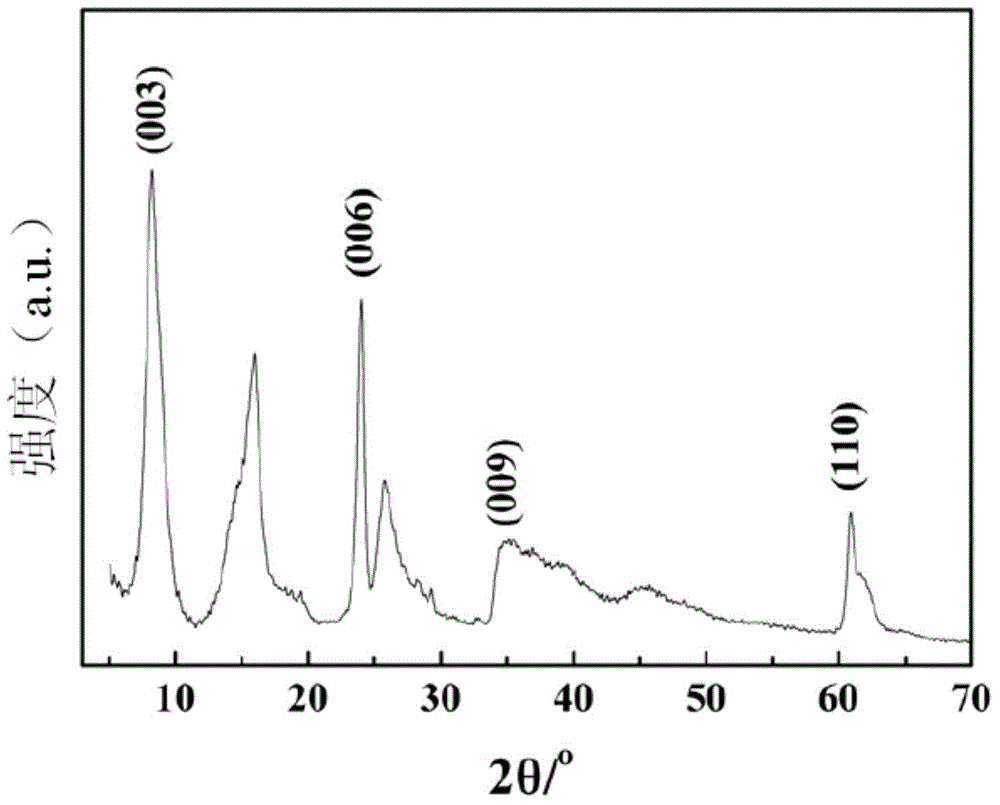

[0042] attached figure 2 The XRD pattern of the cyanuric acid intercalation modified hydrotalcite prepared in Example 11, wherein the diffraction peaks at 23.5 °, 34.5 ° and 61.0 ° are derived from magnesium aluminum hydrotalcite (006), (009) and (110 ) crystal plane diffraction, the diffraction peak at 8.4° comes from the crystal plane diffraction of (003), corresponding to an interlayer spacing of 1.067nm, while the interlayer spacing of nitrate intercalation modified hydrotalcite is 0.75nm, indicating that cyanuric acid Intercalation modified hydrotalcite interlaminar spacing increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point temperature | aaaaa | aaaaa |

| Vicat softening point temperature | aaaaa | aaaaa |

| Vicat softening point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com