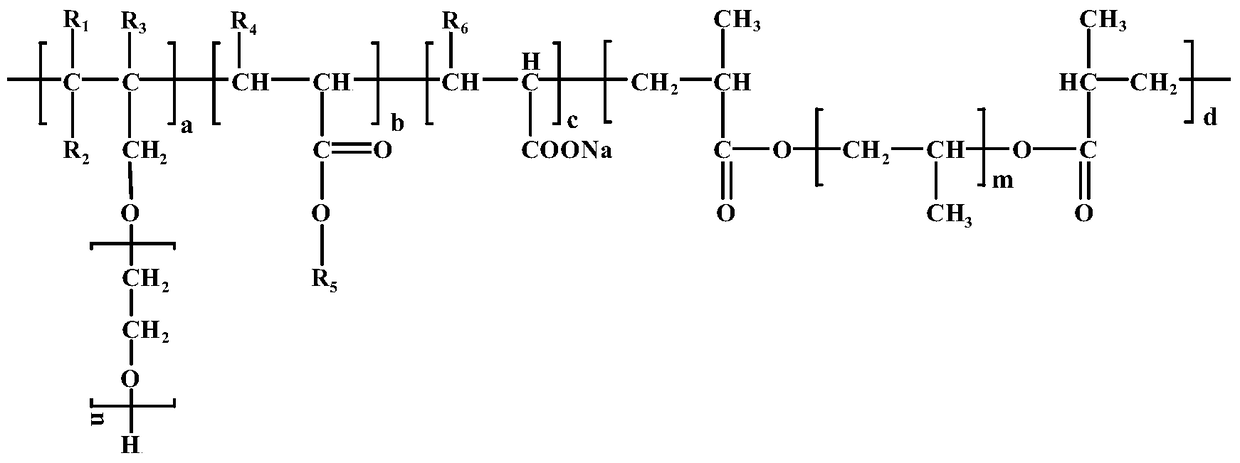

A kind of cross-linked polycarboxylate slump retaining agent and preparation method thereof

A technology of polycarboxylic acid and slump-retaining agent, applied in the field of cross-linked polycarboxylic acid slump-retaining agent and its preparation, can solve the problems of difficult temperature control, narrow range, increase system steric hindrance, etc., and achieve a wide application range , temperature insensitive, the effect of a wide range of synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

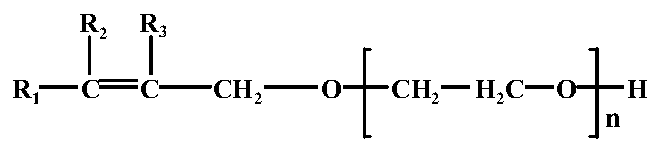

[0050] Get 85 parts of macromonomer isopentenol polyoxyethylene ether (TPEG) (molecular weight 2400) and 85 parts of water into the reaction container, stir until the macromonomer is completely dissolved, drop A, B, C, D four kinds of solutions, the dropping time of A, B, D solution is 3h, the dropping time of C solution is 3.5h, the reaction temperature is controlled at 10 ~ 50 ℃, keep warm for 1.5h after dropping, add NaOH solution to adjust the pH value to 4.5, replenishing water makes the solid content of the reaction solution drop to 40%, to obtain the cross-linked polycarboxylate slump retaining agent;

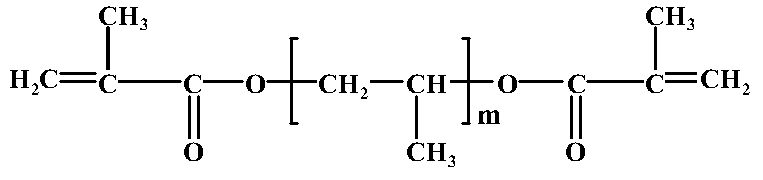

[0051] Among them, A solution is: take 4 parts of unsaturated acid acrylic acid (AA), 8.5 parts of unsaturated ester hydroxyethyl acrylate and 1.2 parts of polypropylene glycol dimethacrylate (m=6), and dissolve them in 10 parts of water to obtain A solution;

[0052] Solution B is: take 0.6 parts of oxidant hydrogen peroxide and dissolve it in 10 parts of water to obta...

Embodiment 2

[0058]Take 88 parts of macromonomer methallyl polyoxyethylene ether (HPEG) (molecular weight 3200) and 88 parts of water into the reaction container, stir until the macromonomer is completely dissolved, and drop A, B, C into it at the same time , D four kinds of solutions, the dropping time is 2h, the reaction temperature is controlled at 10 ~ 50 ℃, after the dropping is completed, keep warm for 2h, add NaOH solution to adjust the pH value to 6, replenish water to make the solid content of the reaction solution drop to 40%, The obtained cross-linked polycarboxylate slump retaining agent;

[0059] Among them, A solution is: take 4 parts of unsaturated acid acrylic acid, 2 parts of unsaturated ester hydroxyethyl methacrylate, 2 parts of hydroxymethyl acrylate and 2.1 parts of polypropylene glycol dimethacrylate (m=10), dissolve in 10 parts of water to obtain A solution;

[0060] Solution B is: take 0.8 parts of oxidant sodium persulfate and dissolve it in 10 parts of water to o...

Embodiment 3

[0066] Take 75 parts of macromonomer isopentenol polyoxyethylene ether (TPEG) (molecular weight 1600) and 75 parts of water into the reaction container, stir until the macromonomer is completely dissolved, and drop A, B1, B2, For C1, C2, and D solutions, the dropping time is 3 hours, the reaction temperature is controlled at 10-50 ° C, and the temperature is kept for 2 hours after the dropping is completed. Add NaOH solution to adjust the pH value to 5.5, and add water to reduce the solid content of the reaction solution to 40%. , to obtain the cross-linked polycarboxylate slump retaining agent;

[0067] Among them, A solution is: take 5 parts of unsaturated acid acrylic acid, 6 parts of unsaturated ester hydroxyethyl acrylate, 7.5 parts of methyl acrylate and 4.5 parts of polypropylene glycol dimethacrylate (m=15), dissolve in 10 parts of water , to obtain A solution;

[0068] B1 solution is: take 0.5 parts of oxidant sodium persulfate and dissolve in 5 parts of water to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com