Commercial semi-trailer closed-loop electronically controlled brake hysteresis compensation device

A technology of electronically controlled braking and compensation devices, which is applied in the direction of braking transmission devices, brakes, and braking safety systems, can solve the problems of uncontrollable trailer braking strength and trailer braking lag, and achieve good market prospects Improved hysteresis, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

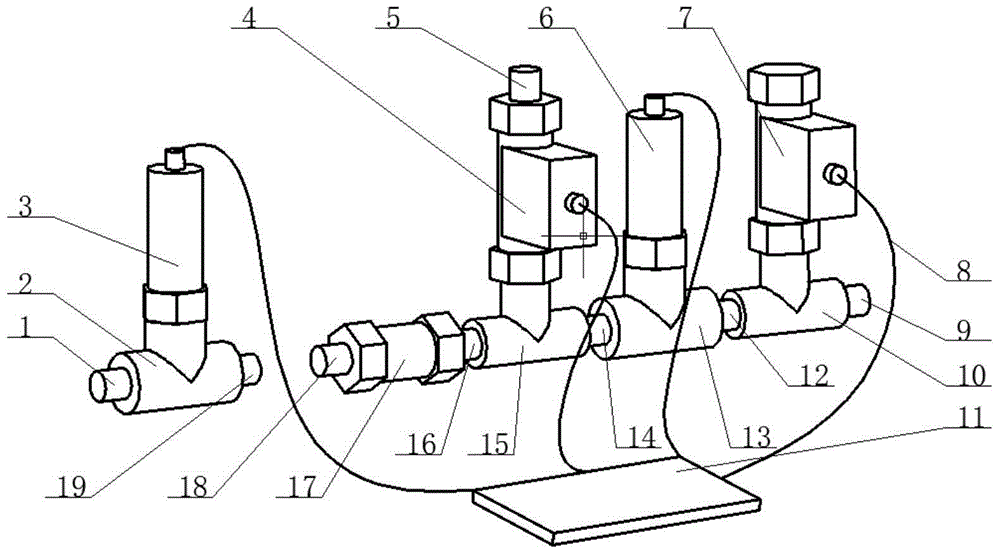

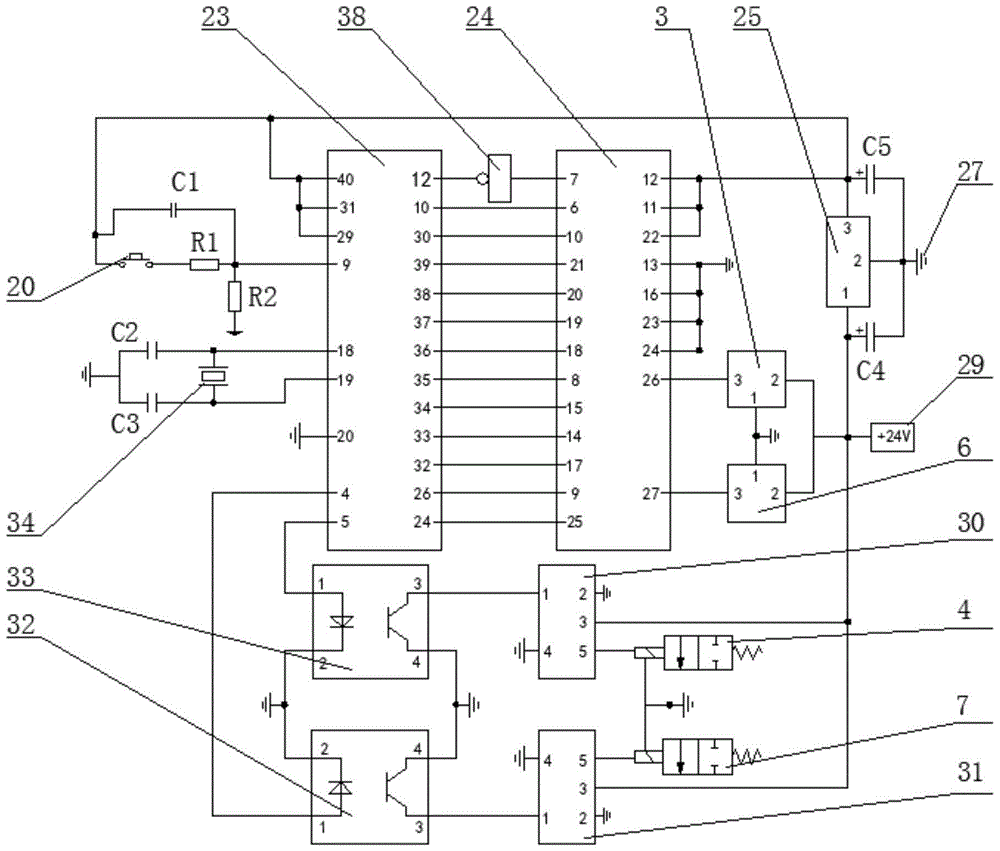

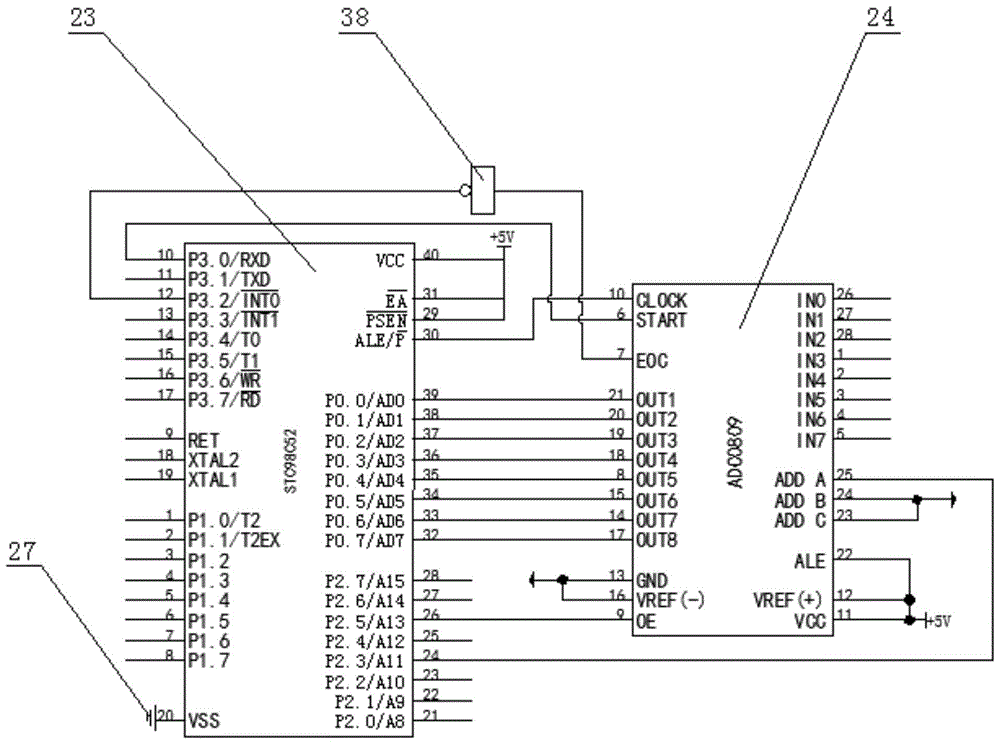

[0035] refer to figure 1 and figure 2 , the commercial semi-trailer closed-loop electric control braking hysteresis compensation device of the present invention is divided into a mechanical part and a controller 11, wherein the mechanical part is further divided into a tractor mechanical part and a trailer mechanical part.

[0036] The mechanical part of the tractor is composed of the first pressure sensor 3 model BST6600, the first tee 2, the first pneumatic pipeline 1 and the second pneumatic pipeline 19.

[0037] The mechanical part of the trailer is composed of the third pneumatic pipeline 18, the check valve 17, the fourth pneumatic pipeline 16, the second tee 15, the first electromagnetic valve 4 of the model KX52310-08, the fifth pneumatic pipeline 5. The sixth pneumatic pipeline 14, the third tee 13, the second pressure sensor 6 of model BST6600, the seventh pneumat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com