Machining process and machining die of shaft tube hollow tube

A technology for processing molds and hollow tubes, which is applied in the field of shaft tube hollow tube processing molds and shaft tube hollow tube processing technology, can solve the problems of high cost, difficulty in machining the inner hole of shaft tube hollow tubes, and low efficiency, so as to avoid processing difficulties Larger, shortened processing time, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

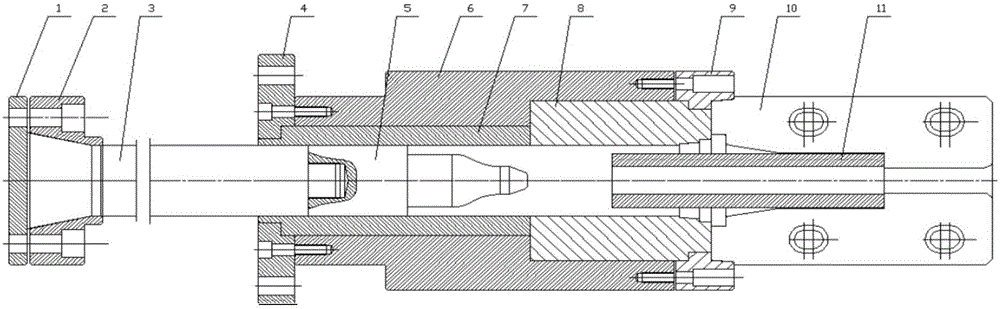

[0054] In the first specific embodiment, the shaft tube hollow tube processing technology provided by the present invention includes the following steps:

[0055] Blanking, preparing a tubular blank with an inner diameter of 32-34mm;

[0056] Therefore, the blank is a pipe fitting with an inner hole, which is conducive to reducing the machining allowance and shortening the processing time in the subsequent processing. Specifically, the height of the blank can be set to 330mm, the outer diameter is generally 65mm, and the inner diameter can be set to 33mm. Of course, other settings can also be made according to specific needs.

[0057] heating the billet;

[0058] It is heated to facilitate the smooth progress of the subsequent extrusion process.

[0059] Clean the scale of the heated billet;

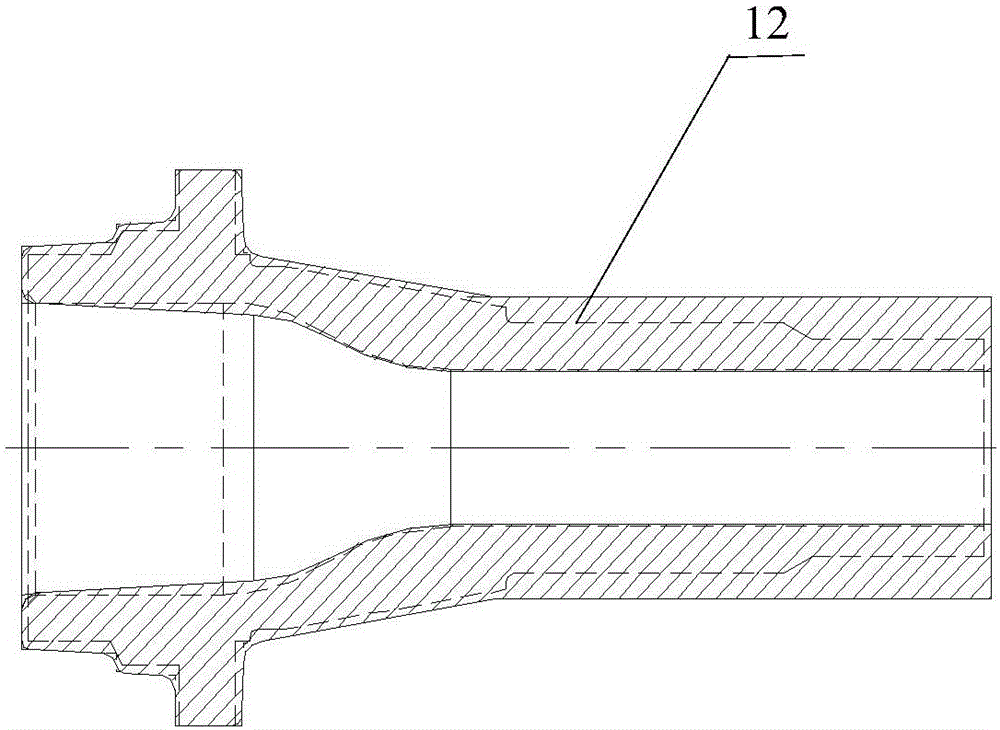

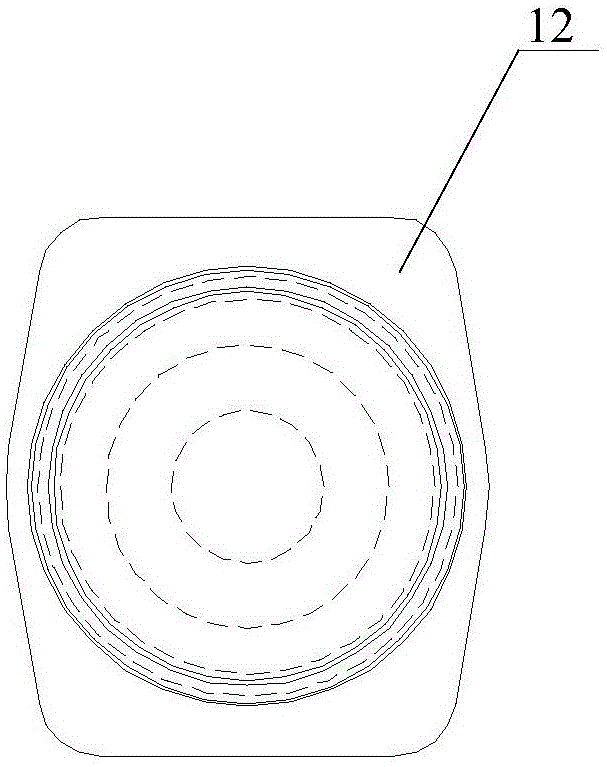

[0060] The blank is passed through the shaft tube hollow tube processing die provided in the above embodiments to forge the inner hole and extrude the shape.

[0061] The blank is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com