A vertical roller mill bypass classification drying raw meal preparation system and process

A roller mill bypass and grading drying technology is applied in the field of building material manufacturing, which can solve the problems of low drying and grading efficiency of materials, difficult control of process parameters, and large system resistance, so as to increase waste heat power generation and material conveying efficiency. The effect of increasing and reducing the air volume of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

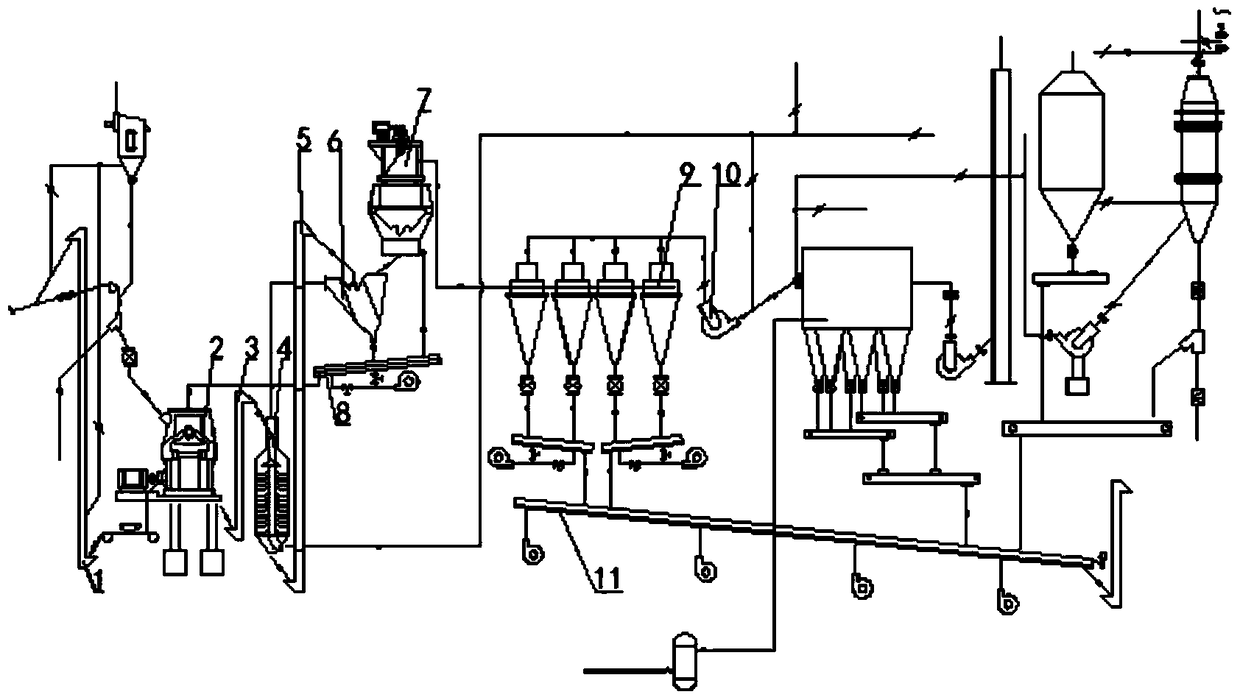

[0025] Such as figure 1 As shown, a vertical roller mill bypass graded drying raw meal preparation system includes a vertical roller mill 2, a raw material elevator 1, a grinding tail elevator 3, a drying equipment 4, a dry material elevator 5, Circulating centrifugal fan 10, cyclone collector 9 and coarse powder air delivery chute 8, the outlet of the raw material elevator 1 is connected to the inlet of the vertical roller mill 2, and the outlet of the vertical roller mill 2 is The feed port is connected to the feed port of the grinding tail lifter 3, the discharge port of the grinding tail lifter 3 is connected to the feed port of the drying equipment 4, and the discharge port of the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com