Improved blast circular cooling machine

A cooling machine and blast ring technology, which is applied in the direction of furnace cooling, processing discharged materials, furnace types, etc., can solve problems such as blockage, and achieve the effects of ensuring normal operation, reducing ash, and uniform wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

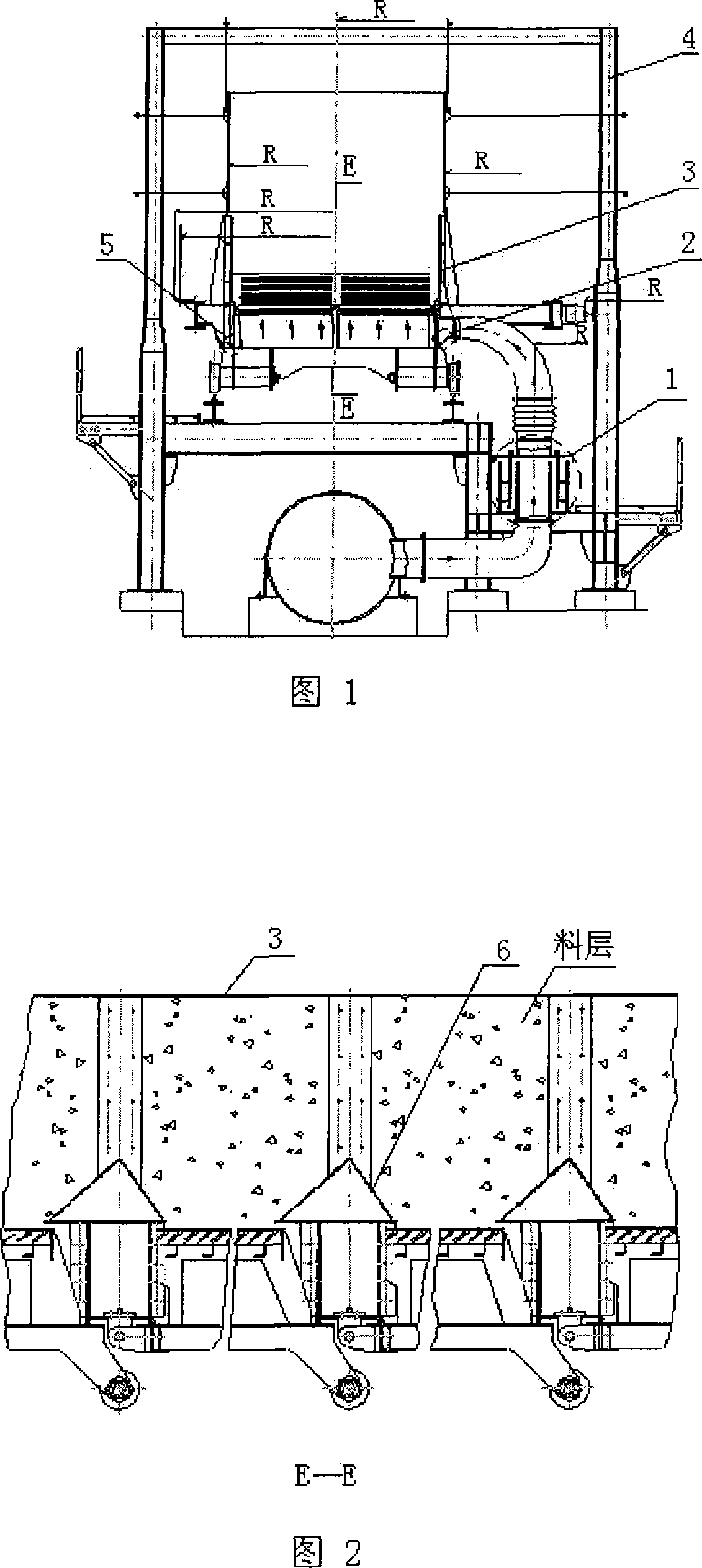

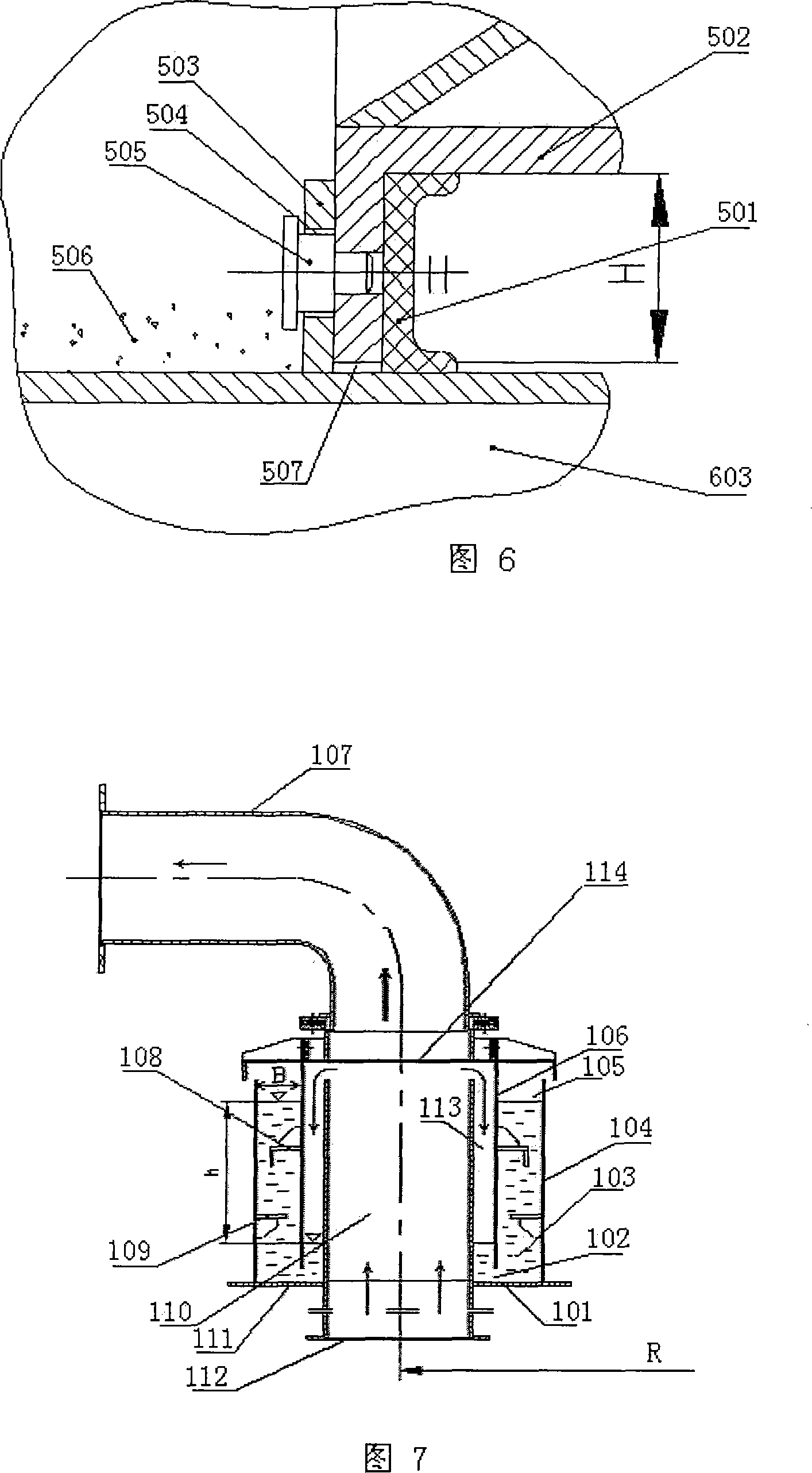

[0039] See Fig. 1, Fig. 2, the present invention has a skeleton 4, double-deck trolley 3, air duct device 1, air supply system etc. are arranged in the skeleton 4, each double-deck trolley 3 is supported by support beam structure 6, double-deck trolley 3. Connect with the air supply system, the air supply system includes a circular air duct 1, and each single double-deck trolley is used as a unit sealing area for sealing to form a contact unit static sealing device. in:

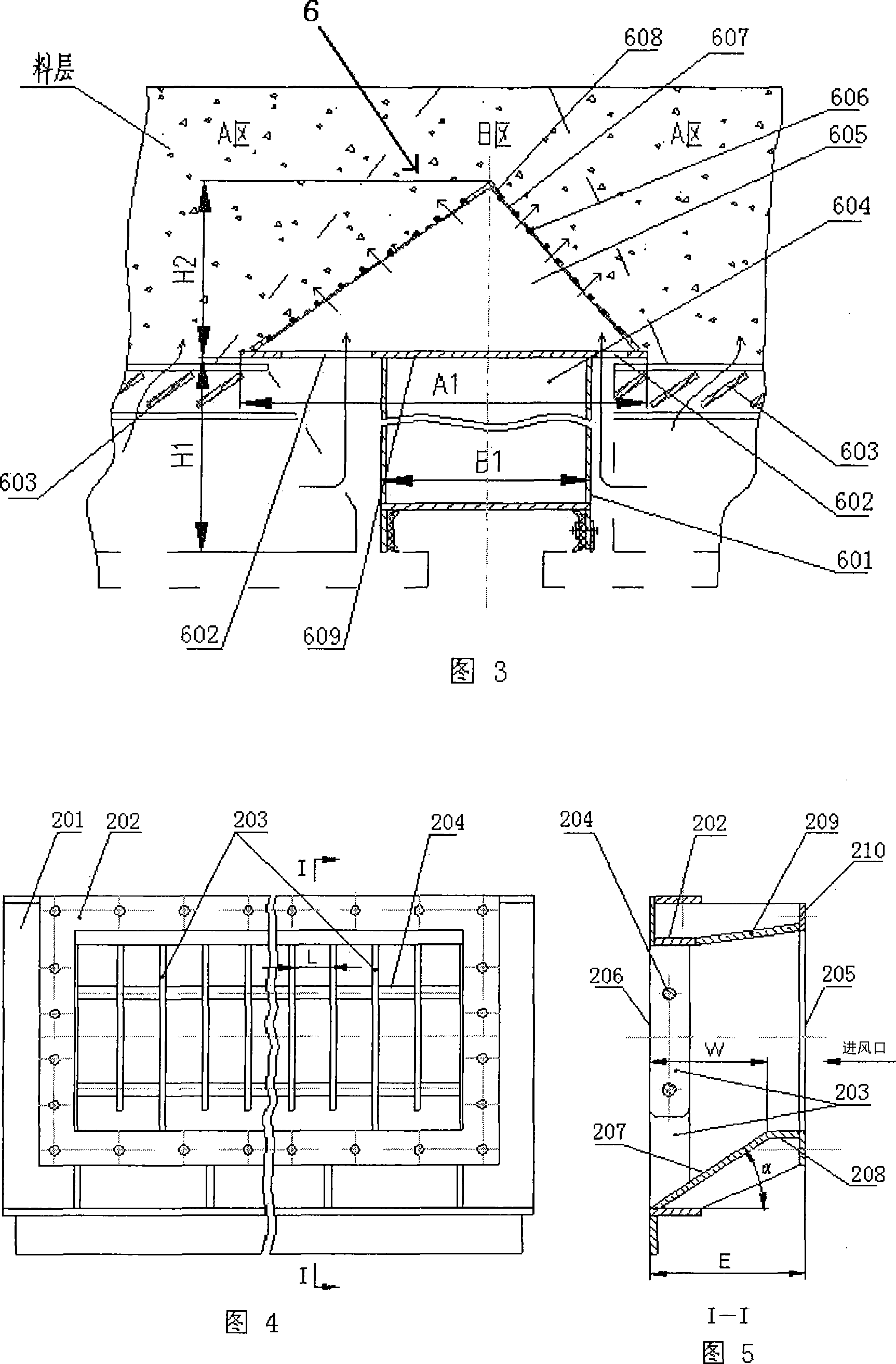

[0040] 1. See Fig. 2 and Fig. 3, the supporting beam structure 6 of the double-deck trolley 3 is based on the rectangular beam 604, and a triangular beam 605 is constructed on the top of the rectangular beam 604, and the upper wing plate 609 of the rectangular beam 604 is extended to both sides Widen, use it as the bottom edge of the triangular beam as the upper cross section, open some rectangular holes 607 on the hypotenuse steel plates 608 at the two waists of the triangular beam 605, and use round steel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com