Resource utilization system for pellet sintering waste gas and method

A technology for sintering flue gas and recycling it. It is applied in chemical instruments and methods, separation methods, and dispersed particle separation. It can solve the problems of substandard flue gas, no denitration efficiency, and easy wear and tear. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

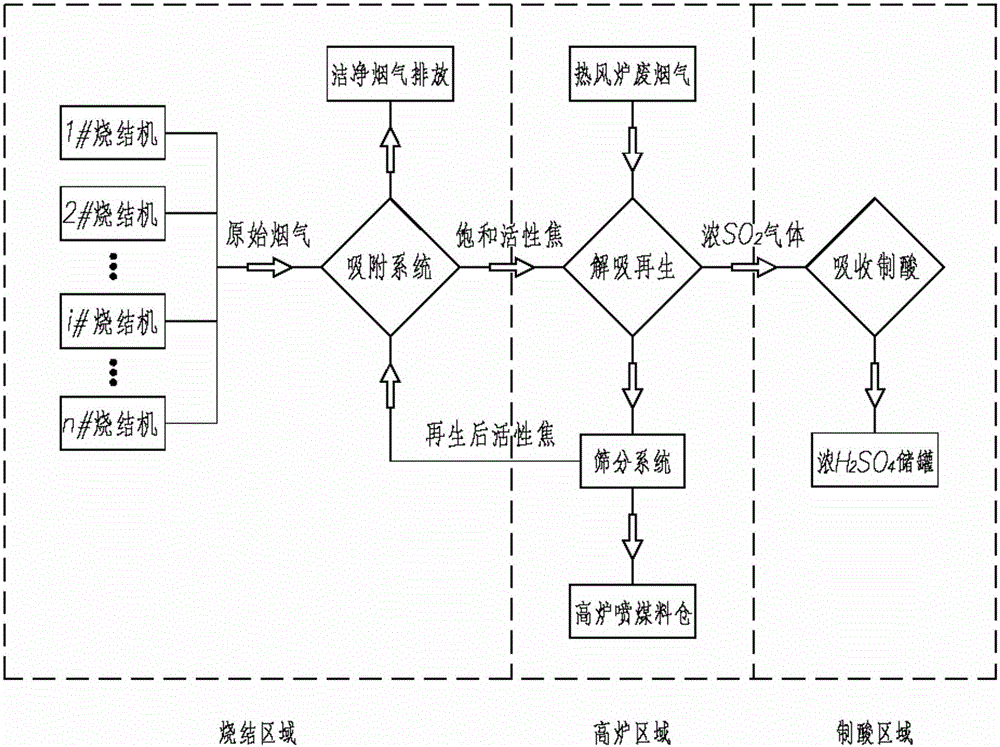

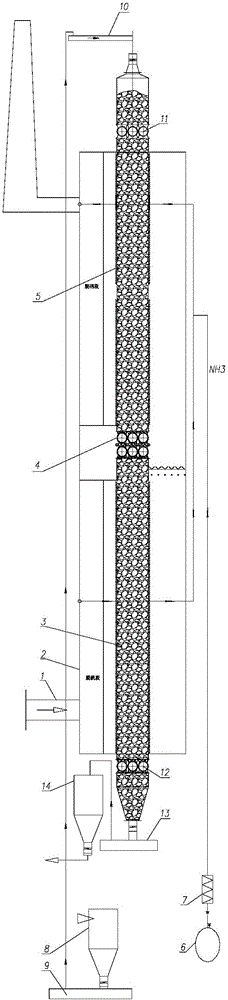

[0052] Such as Figures 1 to 3 As shown, the sintering pellet flue gas recycling system in this embodiment at least includes a sintering flue gas adsorption system, an active coke analysis and regeneration system, and an active coke transportation device, wherein

[0053] The sintering flue gas adsorption system includes an adsorption tower and an ammonia water storage tank. The adsorption tower is connected to the flue gas outlet of the sintering machine through a sintering flue gas pipeline. Two-stage adsorption tower, the first-stage adsorption tower and the second-stage adsorption tower are equipped with active coke adsorbents, and the ammonia water in the ammonia storage tank is evaporated by a heater to enter the second adsorption tower for ammonia gas, The sintering flue gas passes through the first adsorption tower and the second adsorption tower in turn for flue gas purification, and is discharged through the sintering chimney. The saturated activated coke in the adso...

Embodiment 2

[0064] The sintering pellet flue gas recycling system in this embodiment differs from the sintering pellet flue gas recycling system described in Example 1 only in the structure of the desorption tower, but the working principle and process are the same.

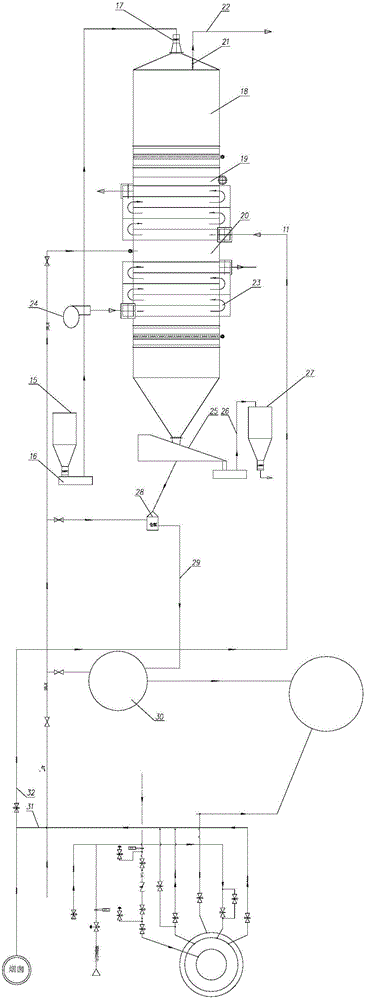

[0065] Such as Figures 6 to 7 As shown, in this embodiment, the desorption tower includes a feeding temporary storage bin 41, an active coke regeneration bin, and an unloading temporary storage bin 422 that are sequentially arranged from top to bottom, wherein the active coke regeneration bin is sequentially arranged from top to bottom It is divided into a feeding straight pipe section 43 , a heating pipe section 411 , a nitrogen-filled excessively feeding pipe section 412 , a cooling pipe section 419 and a discharging straight pipe section 420 .

[0066] Wherein the feeding straight pipe section is provided with an air collecting box 44 outside, and the feeding straight pipe section is provided with a ventilating orifice p...

Embodiment 3

[0076] The process method of sintering pellet flue gas resource utilization in this embodiment, the method at least includes

[0077] Purification of sintering flue gas: the sintering flue gas output from the sintering machine is input into an adsorption tower for purification, wherein the adsorption tower includes a first-stage adsorption tower and a second-stage adsorption tower, and the first-stage adsorption tower, the second-stage adsorption tower Activated coke is respectively arranged in the adsorption tower, and the flue gas passes through the first section of the adsorption tower and the second section of the adsorption tower in turn, and the activated coke in the first section of the adsorption tower will sinter the SO in the flue gas. 2 Adsorption and conversion to generate H 2 SO 4 , stored in the pores of activated coke, ammonia gas is poured into the second adsorption tower, and the activated coke in the second adsorption tower acts as a denitrification low-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com