Current collectors, electrode structures, non-aqueous electrolyte batteries, and electrical storage components

A technology of electrode structures and current collectors, which is applied in the field of electrode structures, non-hydrolytic batteries or power storage components, and current collectors. It can solve the problems of slow lithium deintercalation reaction and low electronic conductivity, and achieve durability. Good, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088]

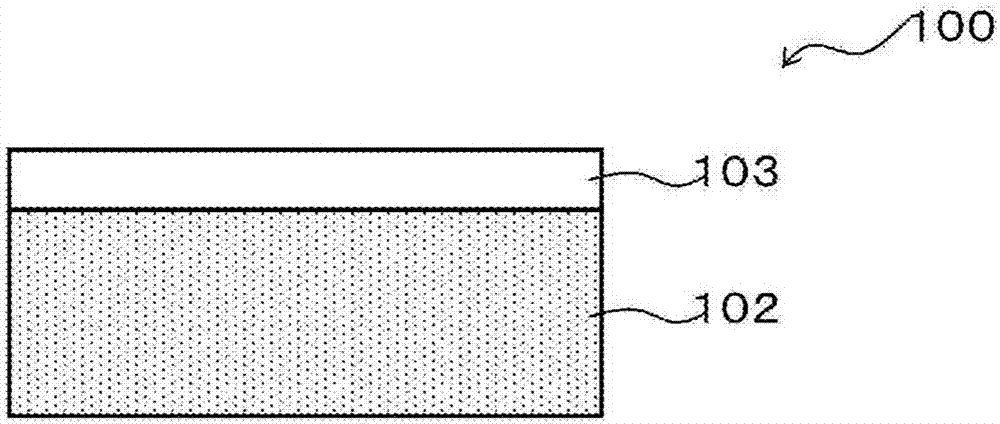

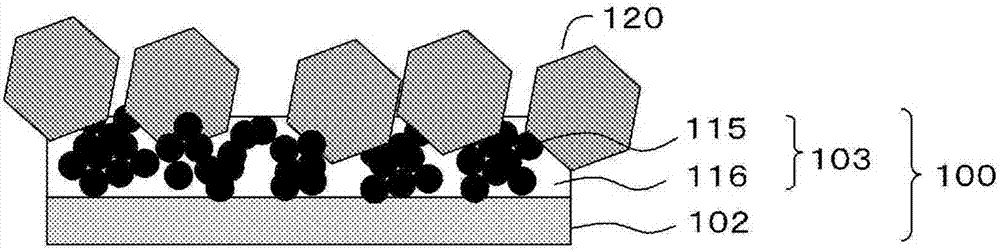

[0089] An aluminum alloy foil with a foil thickness of 15 μm and a tensile strength of 265 MPa was prepared. Next, prepare a nitrocellulose-based resin solution as a resin and acetylene black (AB) as a conductive material (conductive particles), adjust the mass ratio of the solid content so that the resin for the conductive resin layer: conductive material = 60:40, use A dispersing and kneading device (manufactured by PRIMIX, equipment name: T.K. Combimix) was used to obtain a conductive resin solution with adjusted particle size. On one side of the aluminum foil, the conductive resin solution was coated and dried with hot air to form a conductive resin layer to produce a current collector.

[0090]

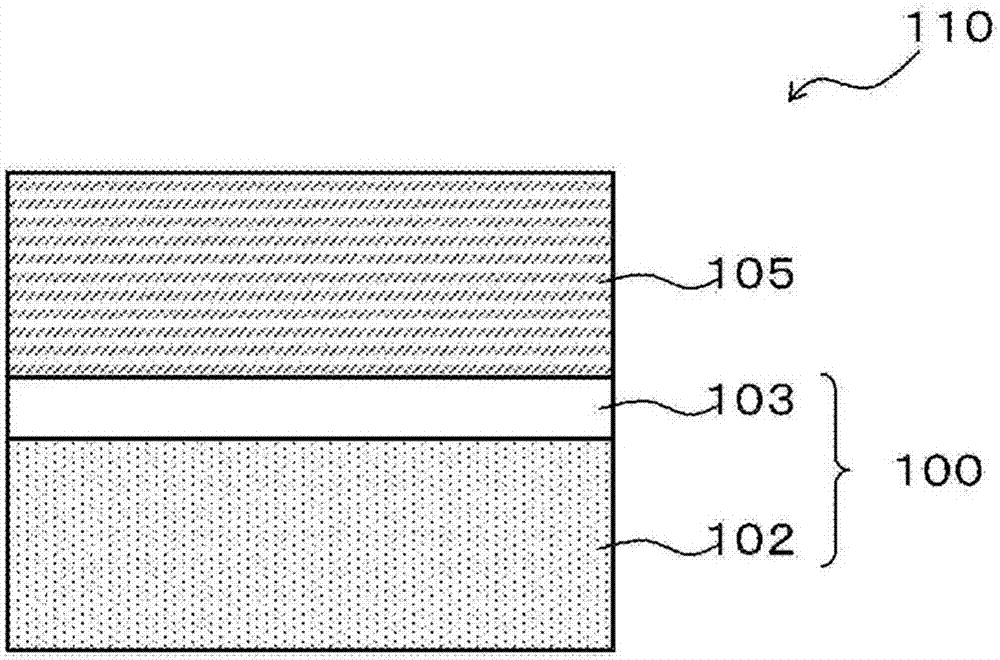

[0091] Prepare lithium iron phosphate with a median diameter (D50) of 2.8 μm as the positive active material, dissolve PVDF (polyvinylidene fluoride) in NMP (N-methylpyrrolidone) to obtain a PVDF solution, and conduction aid Carbon was mixed at a mass ratio of solid...

Embodiment 2

[0096]

[0097] An aluminum alloy foil with a foil thickness of 15 μm and a tensile strength of 265 MPa was prepared. Next, prepare the PVDF resin solution and the conductive material acetylene black as the resin, adjust the mass ratio of the solid content, resin for the conductive resin layer: conductive material=70:30, use a dispersion and kneading device (manufactured by PRIMIX company, the equipment name is : T.K.Combi mix) to obtain the conductive resin solution after adjusting the particle size. On one side of the aluminum foil, the conductive resin solution was coated and dried with hot air to form a conductive resin layer to produce a current collector. Using the current collector, an electrode structure and a single-layer laminated battery were produced in the same manner as in Example 1 for other steps.

Embodiment approach 3

[0099]

[0100] An aluminum alloy foil having a foil thickness of 15 μm and a tensile strength of 195 MPa was prepared. Next, prepare chitosan-based resin solution and conductive acetylene black as resin, adjust the mass ratio of solid content to be resin for conductive resin layer: conductive material=67:33, and use a dispersion and kneading device (manufactured by PRIMIX company, equipment Name: T.K.Combi mix) to obtain the conductive resin solution after adjusting the particle size. On one side of the aluminum foil, the conductive resin solution was coated and dried with hot air to form a conductive resin layer to produce a current collector. Using the current collector, an electrode structure and a single-layer laminated battery were produced in the same manner as in Example 1 for other steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com