Magnetic shielding tube-type electromagnetic induction heating device

A technology of electromagnetic induction heating and magnetic shielding, applied in the direction of induction heating, induction heating control, etc., can solve the problems that the temperature control accuracy of electromagnetic induction heating is difficult to meet the requirements, the temperature control accuracy cannot meet the process requirements, and the ambient temperature rises. Good power saving effect, improved heat preservation effect, moderate and comfortable temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

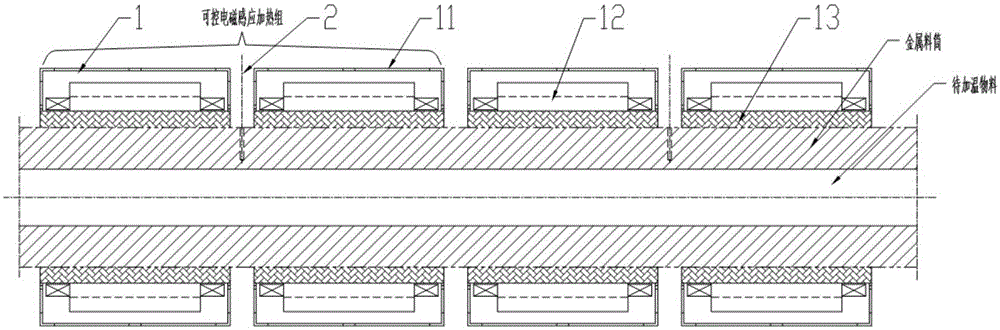

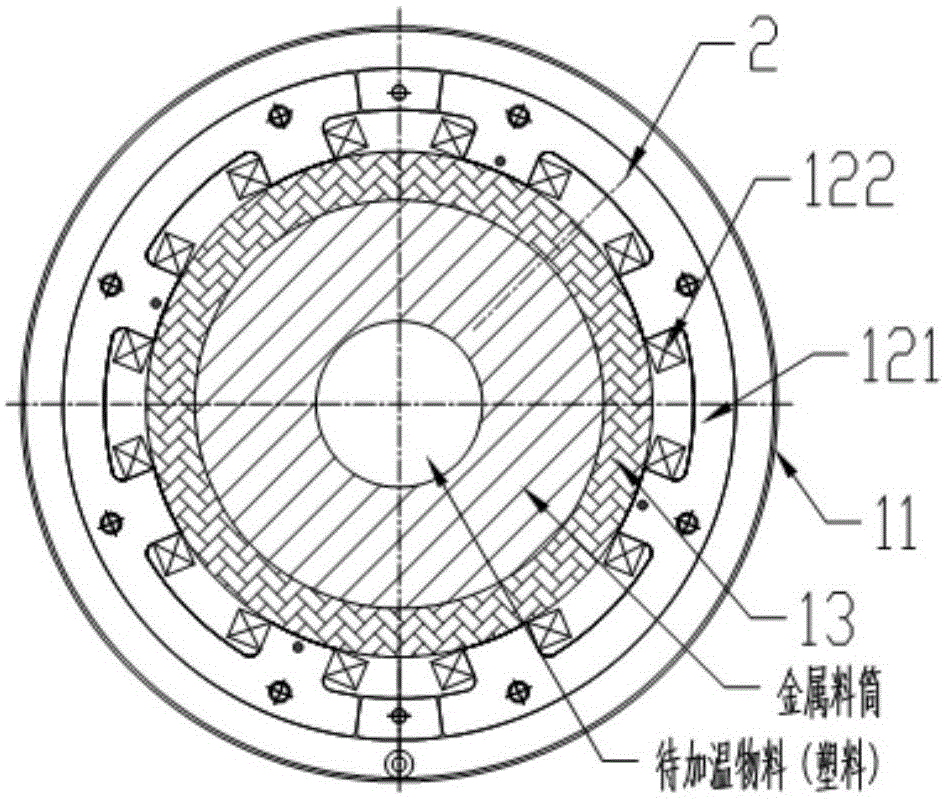

[0021] by figure 1 , figure 2 It can be seen that the magnetic shield tube type electromagnetic induction heating device of the present invention is mainly composed of an electromagnetic induction heating package 1 and a temperature sensor 2. The electromagnetic induction heating package 1 is mainly composed of a protective shell 11, a high-frequency electromagnetic induction body 12 and a thermal insulation layer 13. The electromagnetic induction heating package 1 is ring-wrapped on the outer surface of the barrel, and the barrel is made of conductive material. The electromagnetic induction heating package 1 is provided with a medium-frequency or high-frequency alternating current, and the medium-frequency or high-frequency eddy current is generated in the barrel to perform electromagnetic induction heating on the barrel to heat the material in the barrel.

[0022] by image 3 , Figure 4 It can be seen that the high-frequency electromagnetic induction body 12 of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com