Compact cylindrical ion exchange membrane fuel cell and preparation method thereof

An ion exchange membrane and fuel cell technology, which is applied in the field of compact cylindrical ion exchange membrane fuel cells, can solve the problems of high production cost and large volume of bipolar plates, and achieves compact structure, small overall structure and volume, and damage resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

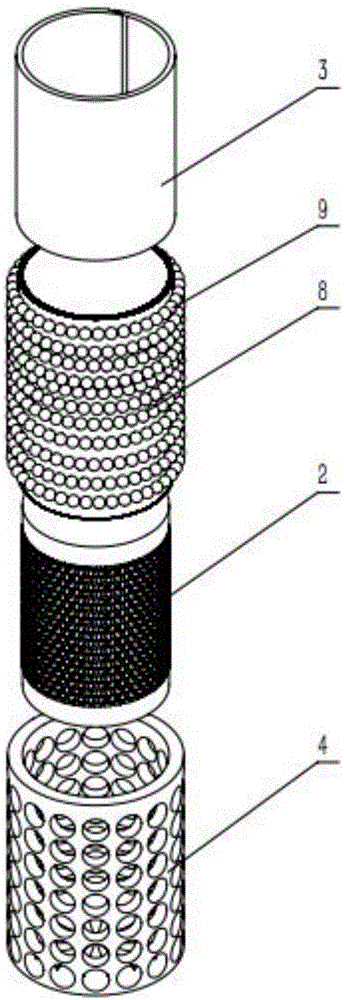

[0051] Such as figure 1 As shown, a compact cylindrical ion-exchange membrane fuel cell 1 sequentially includes a compact pole-membrane integrated fuel chamber 2 , a cathode hydrophobic diffusion layer 3 and a cylindrical sealed collector cover 4 .

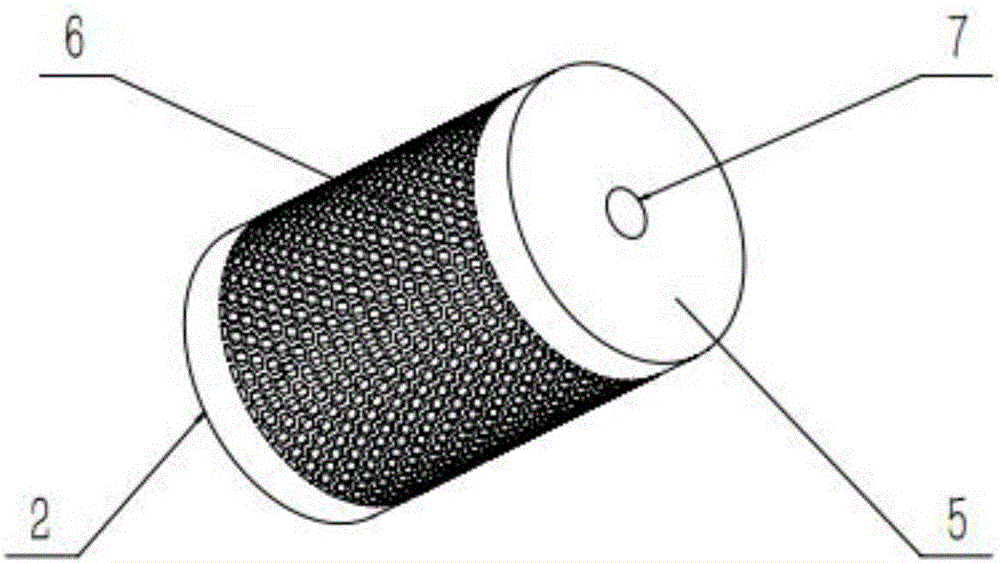

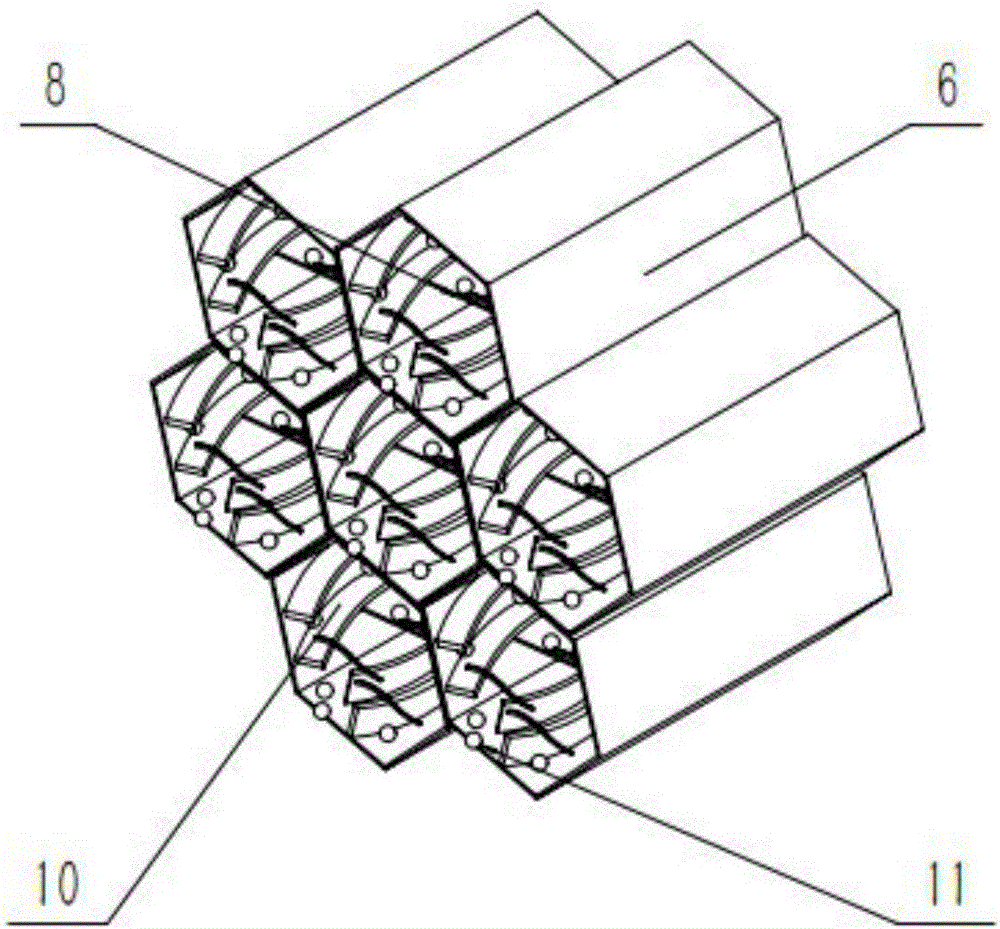

[0052] Such as figure 2 As shown, the compact pole-membrane integrated fuel cavity 2 includes a cylindrical fuel cavity 5, a honeycomb porous structure 6, and a fuel filling hole 7 at the top. Among them such as image 3 As shown, the honeycomb porous structure 6 further includes secondary channels 10 , an anode catalyst layer 11 and an ion exchange membrane 8 attached to the honeycomb porous structure 6 . The fuel filling hole 7 at the top is used for instant filling of liquid fuel to ensure quick start. The honeycomb porous structure 6 has a plurality of secondary channels 10 in the honeycomb holes. The more compact the honeycomb porous structure, the larger the catalytic active surface area, the smaller the mass transfer re...

Embodiment 2

[0058] In embodiment 2, the difference from embodiment 1 is that the cylindrical sealing header 4 is a complete cylindrical cylindrical structure made of memory alloy material, and there are enough circular air holes 12 to make the The air can fully contact the cathode. When assembling, first expand the radius of the memory alloy cylinder sealing collector 4 at low temperature, so that its diameter is slightly larger than the compact polar membrane integrated fuel chamber wrapped with the cathode hydrophobic diffusion layer 3 2. Then put the cylindrical sealed collecting cover 4 on the compact polar membrane integrated fuel chamber 2 wrapped with the cathode hydrophobic diffusion layer 3 at room temperature, and wait for its radius to return to the original radius to achieve interference Cooperate, provide enough external force to make the cathode hydrophobic diffusion layer 3 close to the compact polar membrane integrated fuel cavity 2, such as Figure 7 As shown, the fabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com