Cable production system

A production system and cable technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of low cable production efficiency, increase anti-interference ability and mechanical endurance, uniform wire diameter, and clear process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

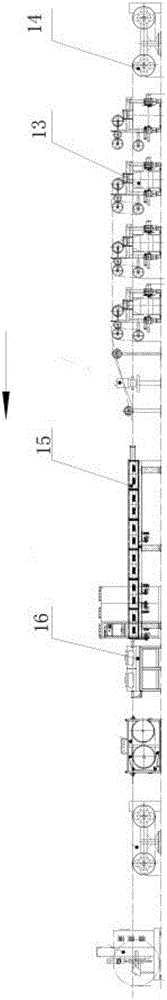

[0022] The invention proposes a cable production system, including a coloring machine, a plastic coating system, a cable forming system, and a jacket system,

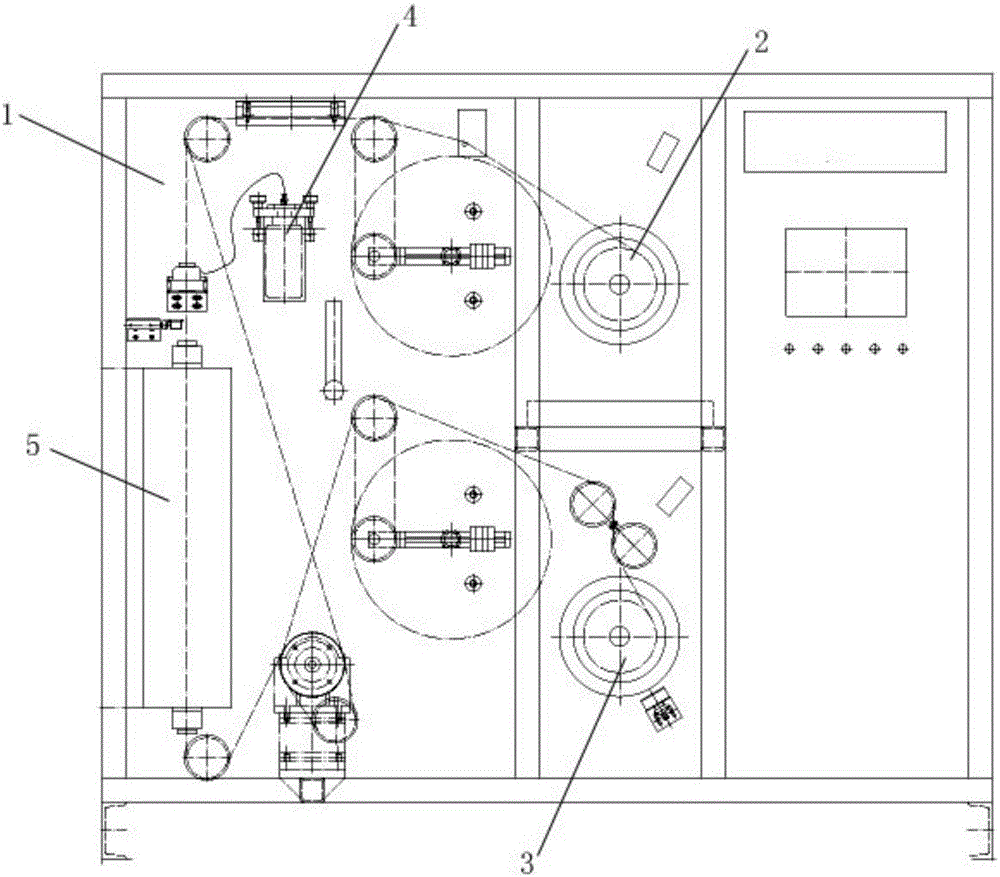

[0023] Described coloring machine comprises fuselage 1, and described fuselage 1 is provided with outlet roller 2, take-up roller 3, inkjet tank 4, curing machine 5, and described outlet roller 2 is positioned at described take-up roller 3 top, so The outlet roller 2 is covered with an optical fiber, and the optical fiber passes through the inkjet tank 4, the curing machine 5 to the take-up roller 3 successively for take-up and take-up;

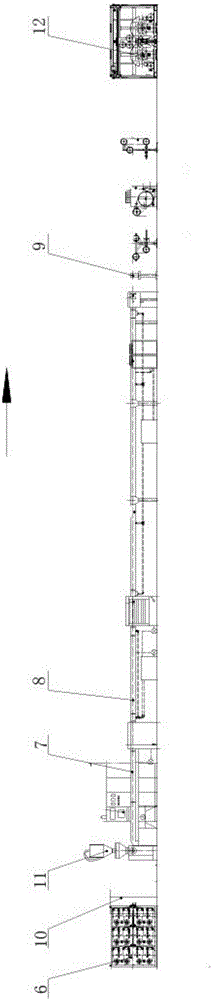

[0024] The plastic covering system includes a pay-off roller group 6, a first water tank 7, a second water tank 8, and a wire diameter detector 9. After the pay-off roller group 6, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com