Automatic Portable Cable Delivery Robot

A cable transmission, portable technology, applied in cable laying equipment, manipulators, electrical program control and other directions, can solve the problems of small space, a lot of manpower, and cable conveyors cannot be used, so as to reduce the use of labor, improve efficiency, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

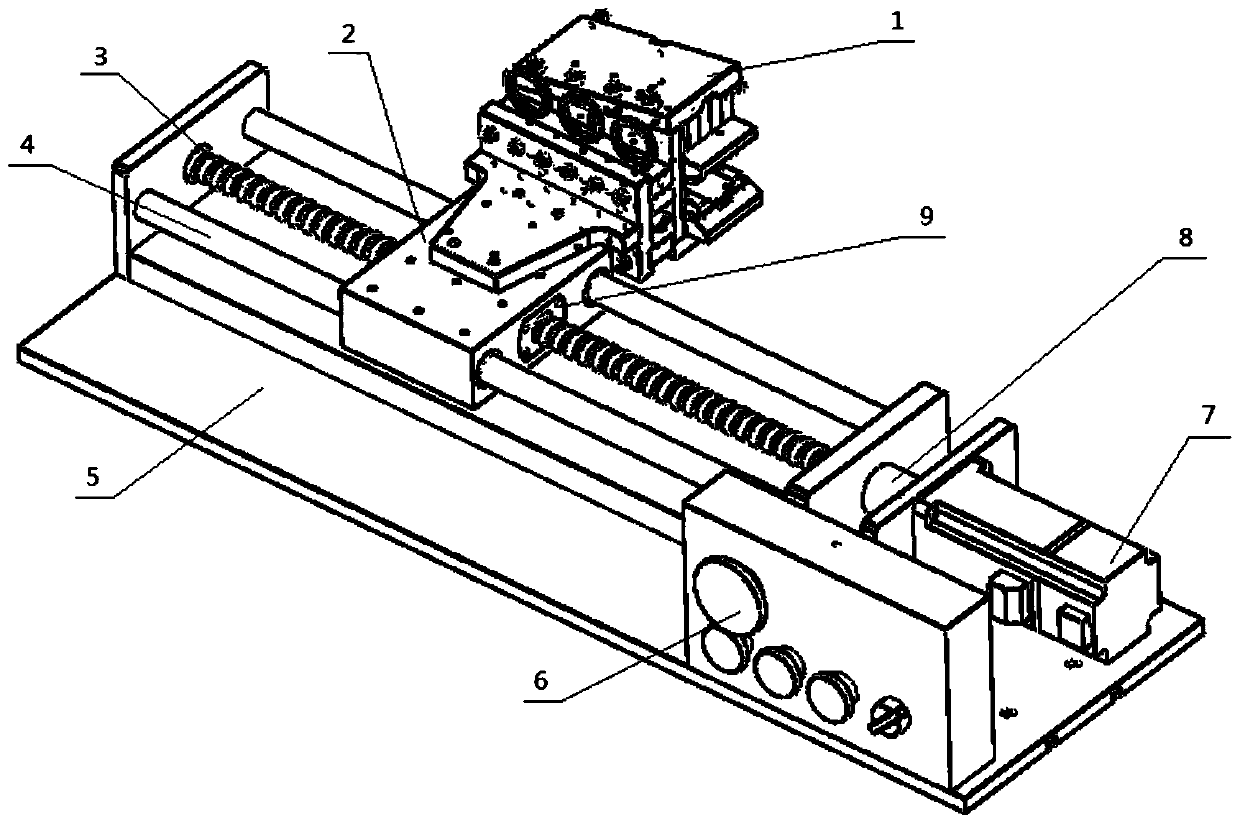

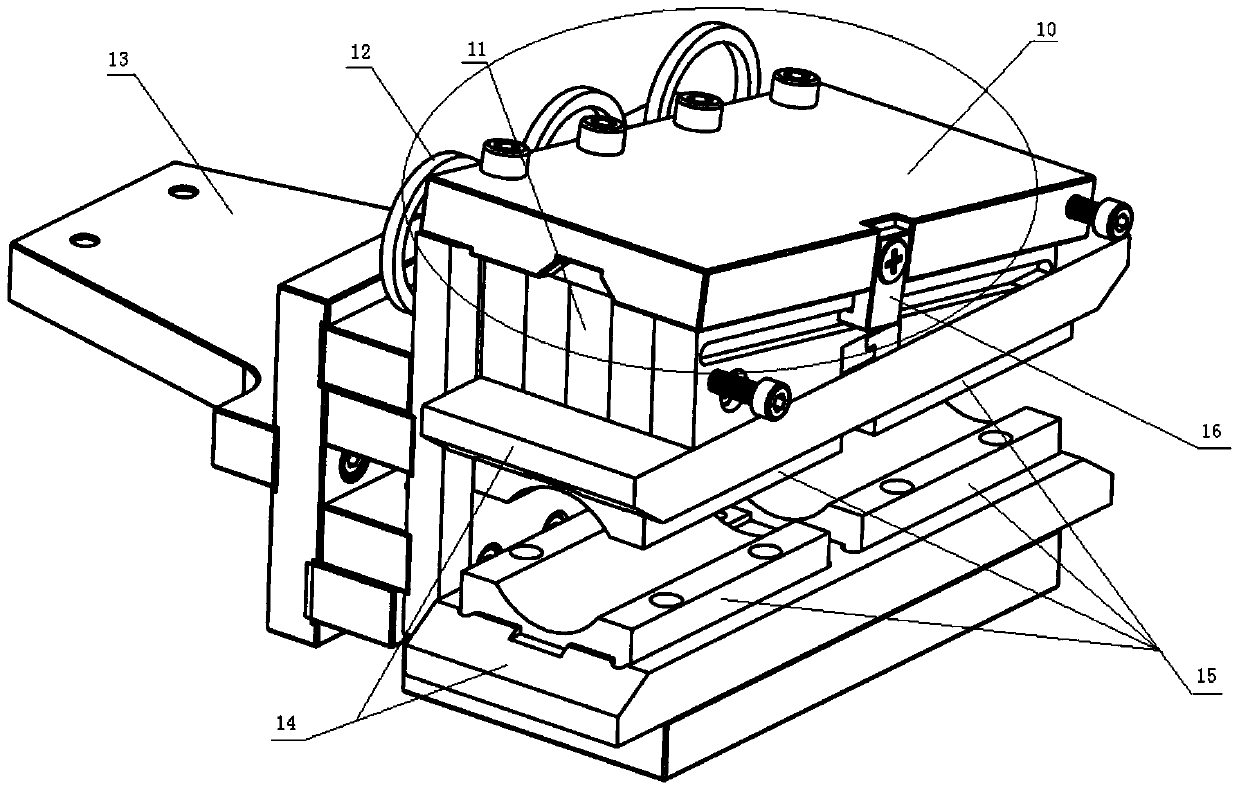

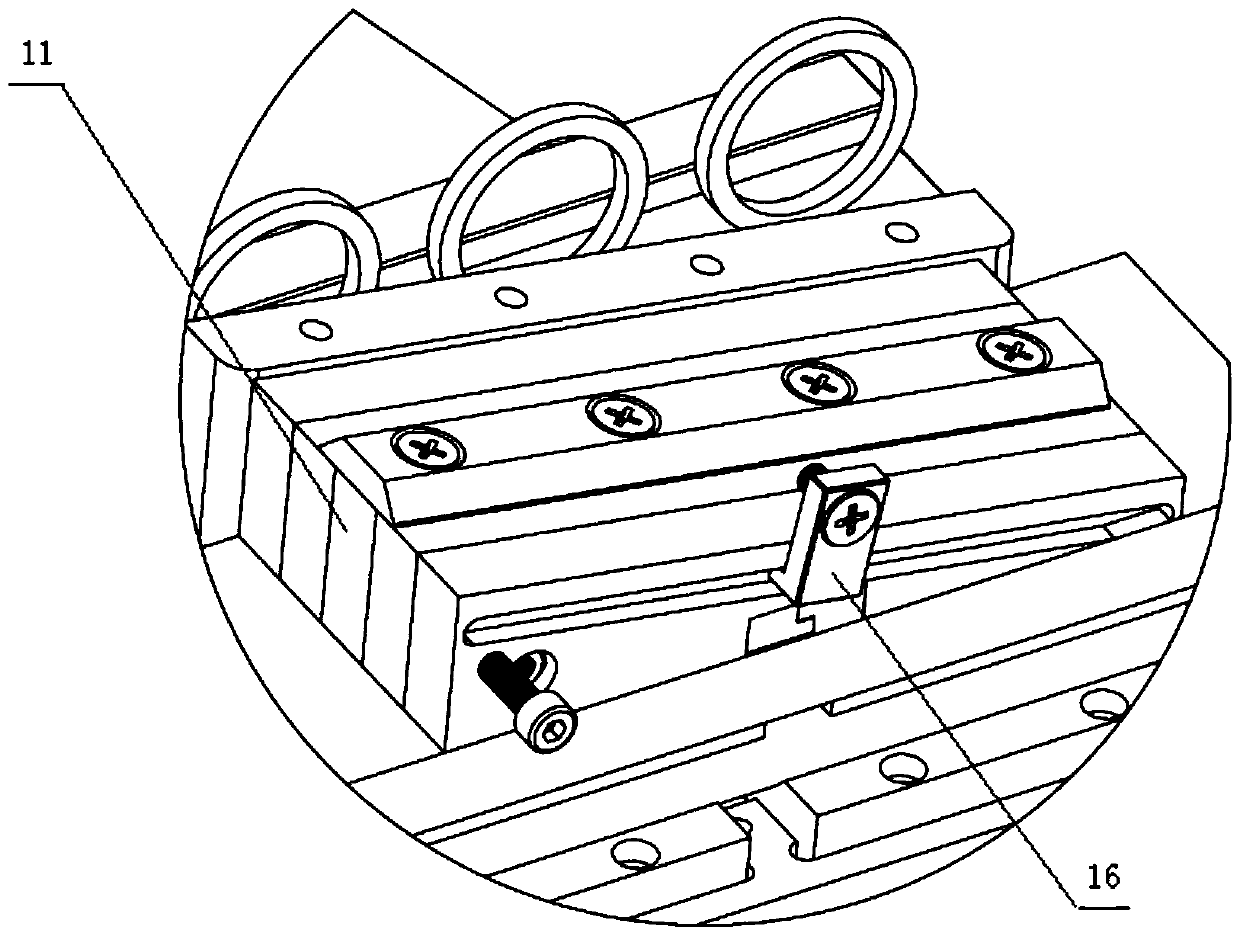

[0020] Such as Figure 1-Figure 3 As shown, the automatic portable cable transmission robot includes a mechanical arm 1, a slide table 2, a ball screw 3, a light rod 4, a base 5, a control panel and a button 6, and a servo motor 7, and a control panel and a button 6 are installed on the base 5 , the servo motor 7, the servo motor 7 is connected to one end of the ball screw 3 through a coupling 8, the other end of the ball screw 3 is installed on the base 5, the ball screw 3 is covered with a screw nut 9, the screw nut 9 Fixedly installed in the sliding table 2, the light rod 4 located on both sides of the ball screw 3 passes through the sliding table 2 and both ends are installed on the base 5, the mechanical arm 1 is installed on the sliding table 2, through the control panel and the button 6 , the movement of the servo motor 7 can be manually controlled to realize functions such as mode selection, switch, jog forward, jog backward, emergency stop, etc. The servo motor 7 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com