Coating assembly line automatic control system

A technology of automatic control system and assembly line controller, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as waste of energy, reduce labor intensity, protect physical health, and work smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

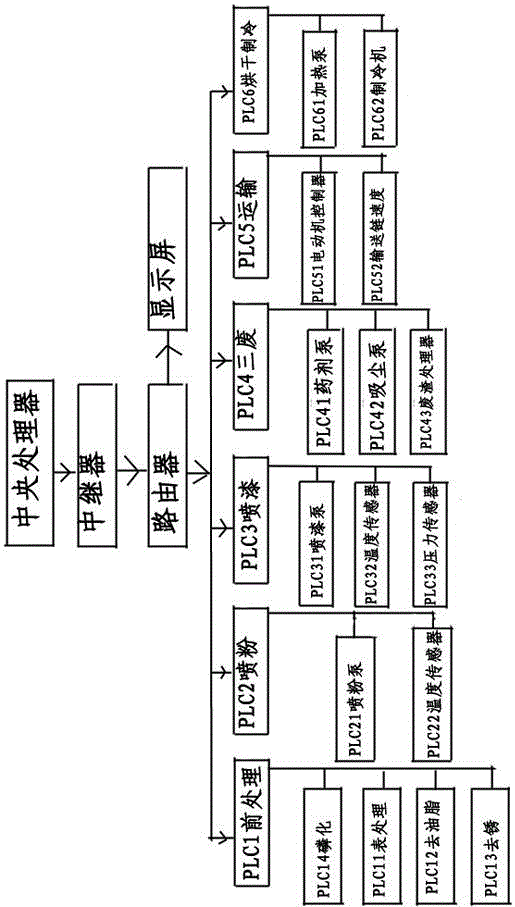

[0017] see figure 1 , the embodiment of the present invention includes:

[0018] The described automatic control system of a painting assembly line includes a central processing unit, the central processing unit adopts an industrial computer, the central processing unit is connected to a repeater through a data bus, and the repeater is connected to a router through a data line. The above-mentioned router is connected with a display screen and six PLC first-level controllers through data lines. The six PLC first-level controllers are: PLC1 pre-processing controller, PLC2 powder spraying controller, PLC3 painting controller, PLC4 three-waste contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com