A mobile multi-angle fast loading vehicle for blasting

A loading vehicle, multi-angle technology, applied in blasting and other directions, can solve problems such as long time, large blockage, rough roads, etc., to increase life and stability, increase discharge speed, and increase charging volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

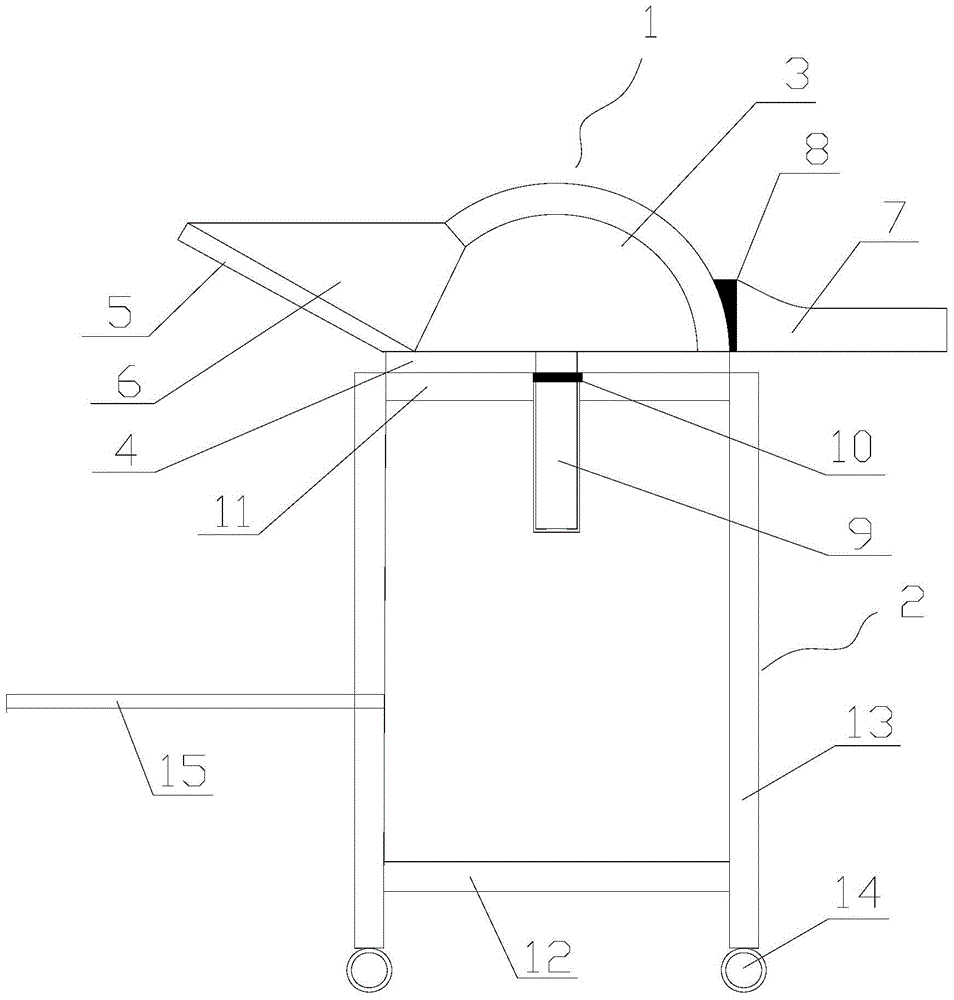

[0028] A kind of movable multi-angle fast loading vehicle for blasting in this embodiment, such as figure 1 Described, comprise hopper 1 and support 2, hopper is located on the support, is provided with feed inlet and discharge port on hopper; Hopper includes semicircular loam cake 3 and flat plate 4 that are connected, and semicircular loam cake covers on On the flat plate, the flat plate is set on the support, the discharge port includes an upper port and a bottom port, the feeding port and the upper port are respectively arranged on both sides of the semi-circular upper cover, and the bottom port is arranged on the flat plate.

[0029] In the hopper, one side of the upper cover of the semi-circular ring is provided with a rectangular mouth, one side of the rectangular mouth is provided with a rectangular baffle 5 placed obliquely, and the two sides of the rectangular baffle are respectively provided with protective plates 6, and the rectangular baffle and the protective plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com