A mobile multifunctional sweat steaming shower room

A multi-functional and mobile technology, applied in heating methods, bathing devices, non-electric variable control, etc., can solve problems such as leakage, material deformation, and rot, and achieve improved leakage prevention performance, improved thermal conductivity, and improved use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

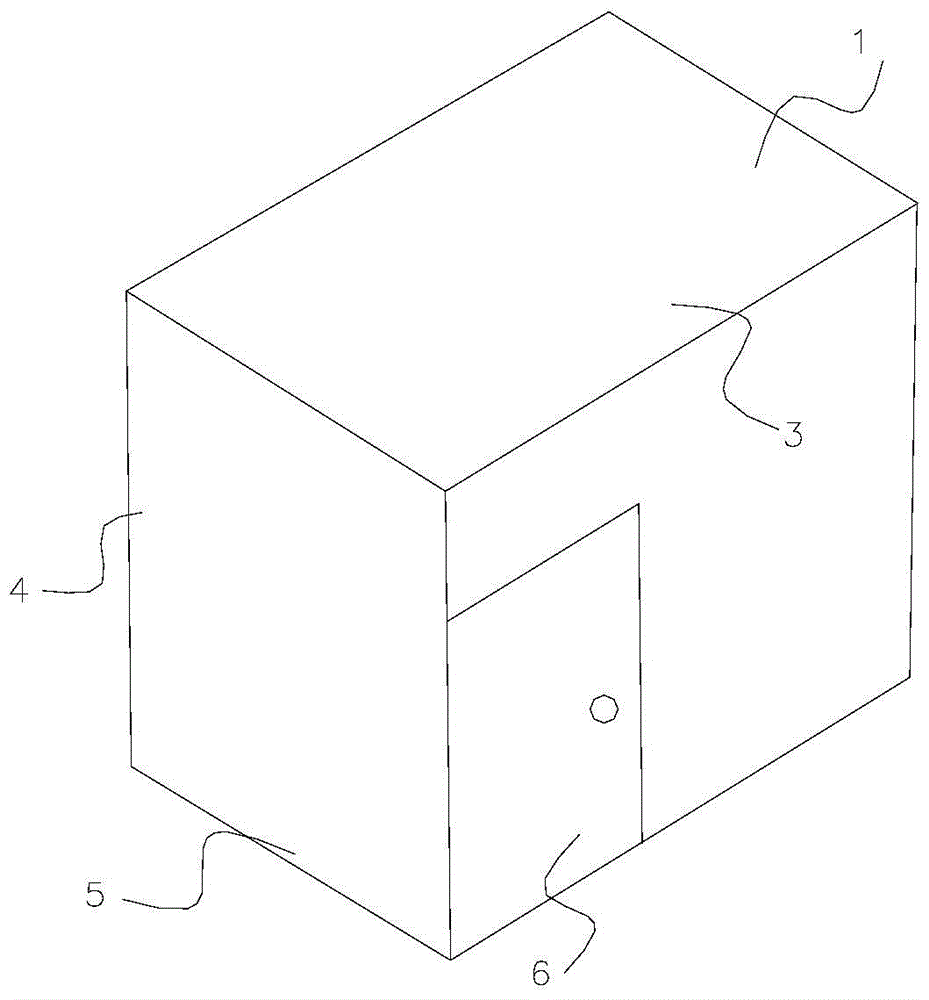

[0037] figure 1 It is a schematic structural diagram of a mobile multifunctional sweat-steaming shower room in an embodiment of the present invention. The mobile multifunctional sweat-steaming shower room includes a room body 1 and a shower nozzle 2 arranged inside the room body 1. The steaming room 1 is a closed space formed by a ceiling 3, a four-sided wall 4, and a floor 5. The wall 4 is provided with a door 6 and a control system 7.

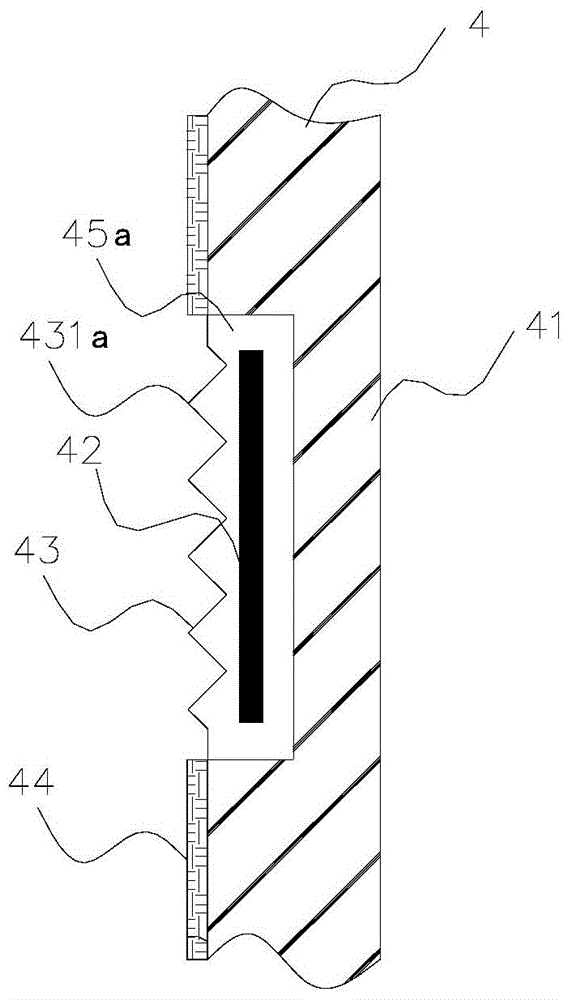

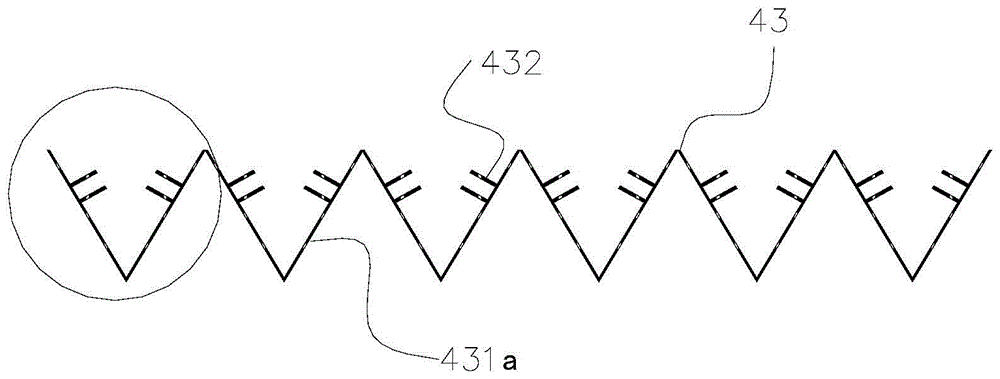

[0038] figure 2 It is a schematic diagram of the structure of the wall in the embodiment of the present invention. The wall 4 is divided into an insulation layer 41, a heating layer 42, a heat conduction layer 43 and a protective layer 44 from the outside to the inside. The insulation layer 41 is provided with a heat conduction groove 45a for accommodating the heating layer 42. The heat conduction groove 45a in this embodiment is It is square and is opened on the surface of the heat preservation layer 41, and the opening of the heat conduction...

Embodiment 2

[0056] Figure 7 It is a schematic diagram of the structure of the wall in Example 2 of the present invention. The wall 4 is divided into an insulation layer 41, a heating layer 42, a heat conduction layer 43, and a protective layer 44 from the outside to the inside. The insulation layer 41 is provided with a heat conduction groove 45b for accommodating the heating layer 42. The opening of the heat conduction groove 45b is used for heat conduction. Layer 43 performs encapsulation. Compared with Embodiment 1, the difference of this embodiment is that the heat conducting groove 45b is provided outside the insulation layer 41. The purpose of this design is to make the insulation layer 41 at the heating layer 42 have sufficient thickness, which can improve the insulation effect of the insulation layer 41 , So as to achieve the purpose of saving energy.

Embodiment 3

[0058] Figure 8 It is a schematic diagram of the structure of the thermal insulation layer in Example 3 of the present invention. Compared with the above-mentioned embodiment, the difference of this embodiment is that the thermal insulation layer 41 is designed as a detachable structure formed by inserting a plurality of sub thermal insulation layers 411. The sub-insulation layer 411 has a small area and can be produced by using scraps. The sub-insulation layer 411 that has problems can be easily replaced. The detachable structure also facilitates the transfer and movement of the steaming room.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com