Digital label paper and its production method

A label paper and digital technology, applied in the field of digital label paper and its production, can solve the problems of poor washability and wear resistance, poor printing clarity, water resistance and temperature difference, etc., to achieve non-slip, good softness, and solve softness poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

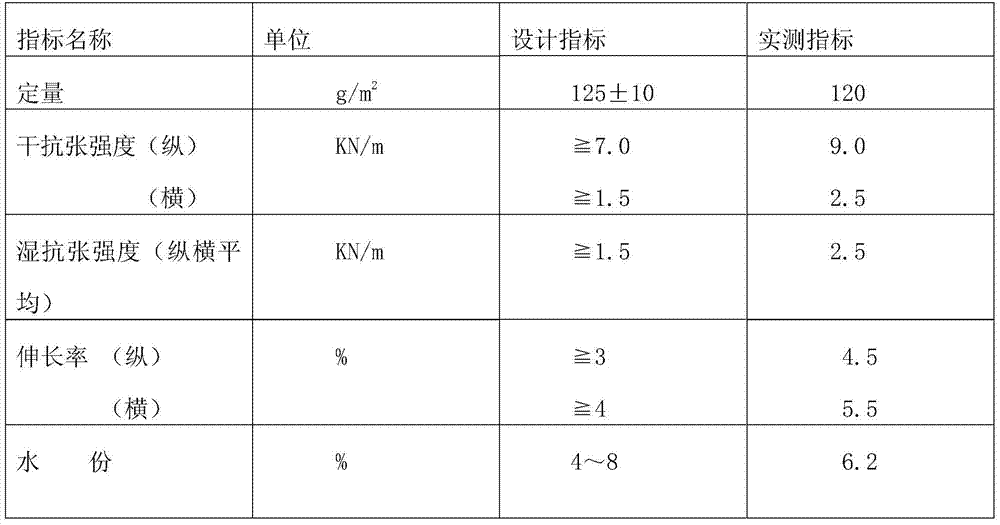

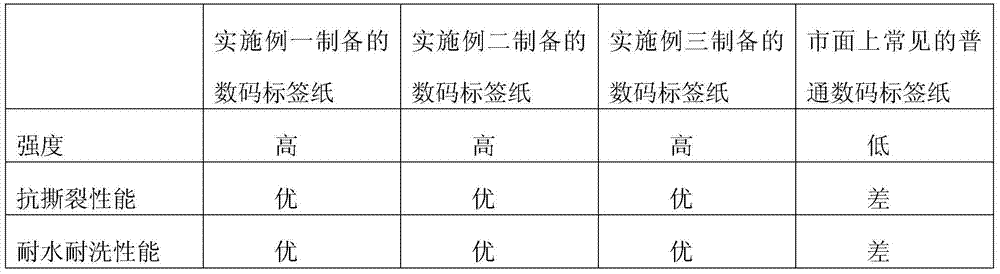

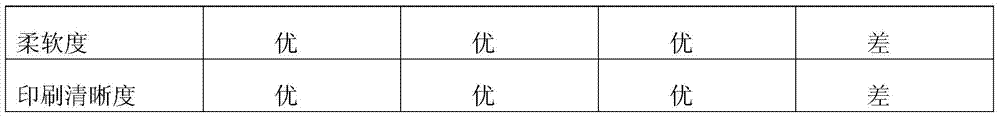

Embodiment 1

[0028] This digital label paper is made of the following raw material proportions by weight: 40 parts of long fiber wood pulp, 5 parts of sisal pulp, 30 parts of chemical fiber, 0.5 part of wet strength agent, 30 parts of coated latex, disperse 5 doses.

[0029] Further, the long-fiber wood pulp is softwood wood pulp.

[0030] Further, the chemical fiber is polyester.

[0031] Further, the wet strength agent is polyester.

[0032] Further, the coating latex is propionate.

[0033] Further, the dispersant is polyacrylamide.

[0034] The production method of above-mentioned digital label paper, comprises the steps:

[0035] The first step is beating treatment. After fully mixing long-fiber wood pulp, sisal pulp and chemical fiber, put it into a hydraulic pulper and add water for mixing and crushing treatment. After crushing, it is output to the half pulp tank, and then pumped Slight beating is carried out in the pulping car, the beating concentration is 3.0%, the beating de...

Embodiment 2

[0043] This digital label paper is made of the following raw material proportions by weight: 50 parts of long-fiber wood pulp, 10 parts of sisal, 40 parts of chemical fiber, 2 parts of wet strength agent, 35 parts of coating latex, dispersant 6 servings.

[0044] Further, the long-fiber wood pulp is softwood wood pulp.

[0045] Further, the chemical fiber is polyester.

[0046] Further, the wet strength agent is polyester.

[0047] Further, the coating latex is propionate.

[0048] Further, the dispersant is polyacrylamide.

[0049] The production method of above-mentioned digital label paper, comprises the steps:

[0050] The first step is beating treatment. After fully mixing long-fiber wood pulp, sisal pulp and chemical fiber, put it into a hydraulic pulper and add water for mixing and crushing treatment. After crushing, it is output to the half pulp tank, and then pumped Slight beating is carried out in the pulping car, the beating concentration is 3.2%, the beating d...

Embodiment 3

[0058] This digital label paper is made of the following raw material proportions by weight: 60 parts of long-fiber wood pulp, 15 parts of sisal pulp, 50 parts of chemical fiber, 3 parts of wet strength agent, 40 parts of coated latex, disperse 8 doses.

[0059] Further, the long-fiber wood pulp is softwood wood pulp.

[0060] Further, the chemical fiber is polyester.

[0061] Further, the wet strength agent is polyester.

[0062] Further, the coating latex is propionate.

[0063] Further, the dispersant is polyacrylamide.

[0064] The production method of above-mentioned digital label paper, comprises the steps:

[0065] The first step is beating treatment. After fully mixing long-fiber wood pulp, sisal pulp and chemical fiber, put it into a hydraulic pulper and add water for mixing and crushing treatment. After crushing, it is output to the half pulp tank, and then pumped Slight beating is carried out in the pulping car, the beating concentration is 3.5%, the beating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com