Thermo-stable oriented silicon steel making method

A technology of oriented silicon steel and manufacturing method, which is applied in the field of thermally stable oriented silicon steel manufacturing, can solve problems such as low processing efficiency, limited reduction range, and slow scanning speed, and achieve the effects of improving production efficiency, reducing iron loss effect, and increasing processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

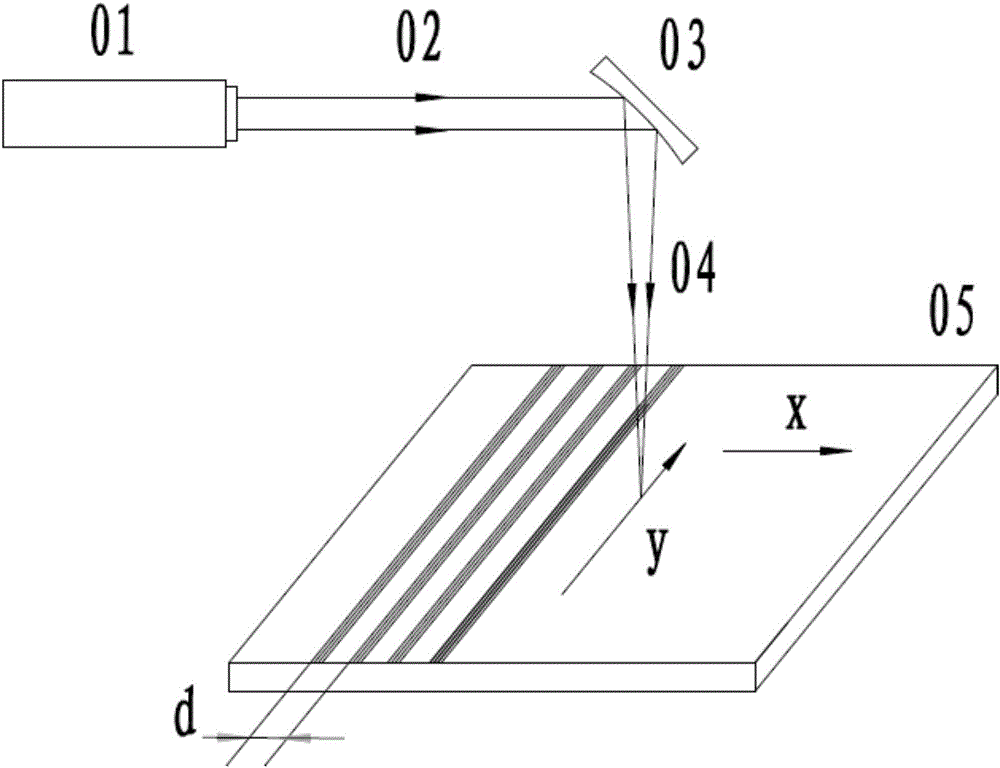

[0046] like figure 1 Shown, the manufacturing method of heat-stable grain-oriented silicon steel of the present invention comprises the steps:

[0047] Step 1: Pretreatment, take domestically produced oriented silicon steel sheets, scrub them with absolute alcohol to remove grease and other stains, and dry them in a dryer at 130°C for 10 minutes;

[0048] Step 2: clamping and fixing, place the oriented silicon steel sheet processed in step 1 on the processing platform, and turn on the negative pressure to fix and clamp;

[0049] Step 3: Scanning, the scanning diagram is as follows figure 2 . Femtosecond laser 1 is used to output parallel laser beam 2 with a wavelength of 343nm. After passing through concave mirror 3, it converges into focused laser beam 4 and scans on oriented silicon steel 5. The scanning direction y of the laser beam is perpendicular to the rolling direction x of oriented silicon steel 5. .

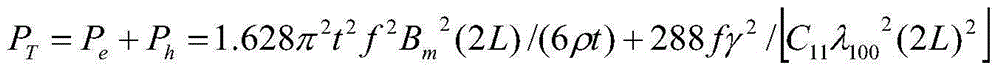

[0050] Scan with a laser scanning speed of 100mm / s, and the lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com