Water quenching automation equipment

An automatic equipment and water-cooling technology, applied in the field of machinery, can solve the problems of slow cooling speed, affecting the process requirements of the workpiece, and the inability to cool the workpiece, so as to achieve uniform cooling and improve the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

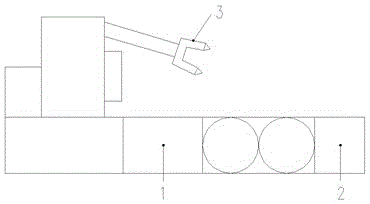

[0023] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0024] Such as figure 1 As shown, the present invention provides a water-cooled quenching automation equipment, which includes a quenching device, a cooling device, and a clamping device 3; the quenching device performs a quenching procedure on a workpiece, and the clamping device 3 The workpiece is clamped into the cooling device;

[0025] The quenching device includes a quenching machine tool and a control power supply, and the control power supply is used to control the quenching machine tool to perform quenching treatment on the workpiece;

[0026] The gripping device 3 includes a mechanical arm and a controller, and the controller controls the mechanical arm so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com