Polyurethane glue for environment-friendly sports field and preparation method of glue

A technology of polyurethane glue and plastic, applied in the field of sports, can solve problems such as adverse environmental effects and human body damage, and achieve the effects of optimizing curing time, reducing moisture, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

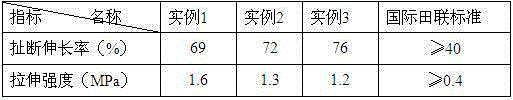

Examples

example 1

[0025] A preparation method of polyurethane glue for environment-friendly sports venues, comprising the following steps: Step 1, according to the weight ratio of 1:3:3, weigh nano-microcapsule powder, nano-silica and absolute ethanol, mix them at 45KHz Ultrasonic dispersion at high frequency for 23 minutes, and then carry out suction filtration under the vacuum condition of 0.098MPa, stop the suction filtration when there are no more ethanol droplets dripping, take out the filtrate, put it in an oven, and carry out 30°C× After drying for 6 hours and preheating at 50°C×20min, take out the preheated material, put it in a press, pre-press it at 2MPa for 5min, and then press at 5MPa and 145°C for 30min, naturally After being cooled to room temperature, white carbon black nanocapsule powder was prepared, which was set aside;

[0026] Step 2. Weigh sodium borate and molecular sieve according to the weight ratio of 2:100, dissolve all the sodium borate in deionized water, then add th...

example 2

[0031] A preparation method of polyurethane glue for environment-friendly sports venues, comprising the following steps: Step 1, according to the weight ratio of 1:3:3, take nano-microcapsule powder, nano-silica and absolute ethanol, mix them in 50KHz Ultrasonic dispersion at high frequency for 20 minutes, then suction filtration under vacuum condition of 0.098MPa, stop suction filtration when there are no more ethanol droplets dripping, take out the filtrate, put it in an oven, and carry out 30℃× After drying for 6 hours and preheating at 50°C×20min, take out the preheated material, put it in a press and pre-press it at 2MPa for 5min, and then heat press it at 5MPa and 150°C for 28min, naturally After being cooled to room temperature, white carbon black nanocapsule powder was prepared, which was set aside;

[0032]Step 2. Weigh sodium borate and molecular sieve according to the weight ratio of 2:100, dissolve all the sodium borate in deionized water, then add the weighed mole...

example 3

[0037] A preparation method of polyurethane glue for environment-friendly sports venues, comprising the following steps: Step 1, according to the weight ratio of 1:3:3, take nano-microcapsule powder, nano-white carbon black and absolute ethanol, mix them in 40KHz Ultrasonic dispersion at high frequency for 25 minutes, and then carry out suction filtration under a vacuum condition of 0.098MPa, stop the suction filtration when there are no more ethanol droplets dripping, take out the filtrate, put it in an oven, and carry out 30°C× After drying for 6 hours and preheating at 50°C×20min, take out the preheated material, put it in a press and pre-press it at 2MPa for 5min, and then heat press at 5MPa and 155°C for 28min, naturally After being cooled to room temperature, white carbon black nanocapsule powder was prepared, which was set aside;

[0038] Step 2. Weigh sodium borate and molecular sieve according to the weight ratio of 2:100, dissolve all the sodium borate in deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com