Energy-saving, heat-insulating and environment-friendly coating material for glass and production method thereof

A coating material and production method technology, applied in the field of energy-saving thermal insulation coating film, can solve the problems of poor thermal insulation and stability, excessive volatile organic solvent content, narrow thermal insulation band, etc., and achieve excellent mechanical and chemical resistance properties. , Overcome the effect of narrow heat insulation band and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

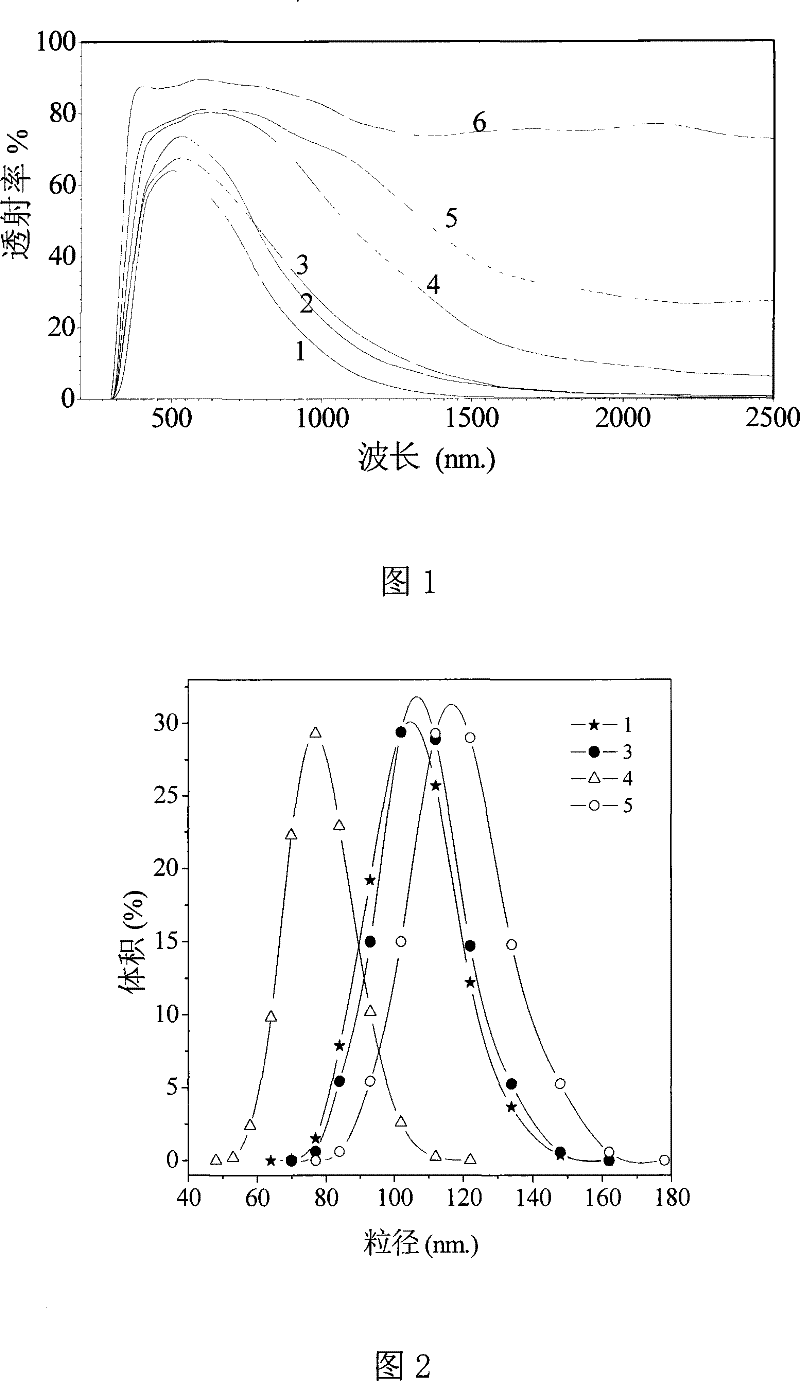

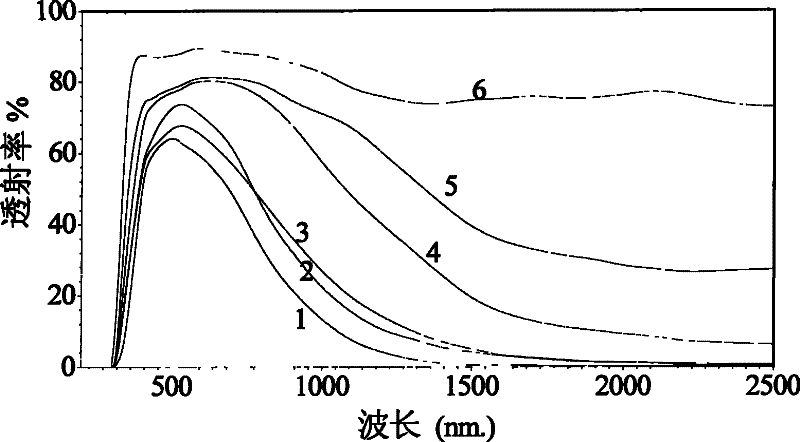

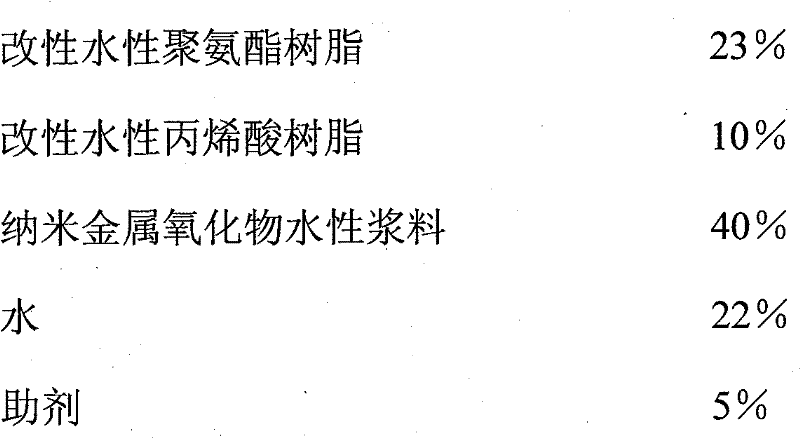

[0027] The formulations of energy-saving, heat-insulating and environment-friendly coating materials for glass in Examples 1-5 are shown in Table 1. Among them, the nano-metal oxide aqueous slurry is combined into a nano-water dispersion by stirring and dispersing the nano-coating film material in the patent "ZL00129358.3" and water at a temperature of 100-400°C and a pressure of 0.1-40MPa In order to have a better dispersion effect, the nano-coating material in the present invention can also be prepared without adding coupling agent and surface coating agent when making (that is, in the final process of the original patent "ZL00129358.3" preparation method), brackets The inner value is the solid content of the nano metal oxide aqueous slurry, and the particle size is 40-200nm. The described modified water-based polyurethane resin, modified water-based acrylic resin, and auxiliary agents (such as leveling agent, wetting agent, defoamer, etc.) can directly adopt commercially av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com