Method for preparing modified chitosan sponge structure material and appliance

A structural material, chitosan technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve toxic reagents, difficult material molding, low adsorption efficiency, harsh reaction conditions, etc. problems, to achieve the effect of increasing active adsorption sites, not easy to dissolve, and simple reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

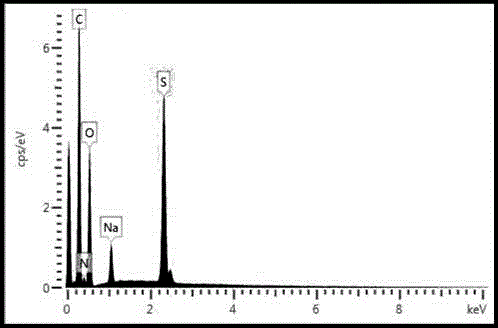

Image

Examples

specific Embodiment approach 1

[0029] Specific embodiment one: the preparation method of a kind of modified chitosan sponge structure material described in the present embodiment is completed according to the following steps:

[0030] 1. Add chitosan and ammonium thiocyanate to absolute ethanol, condense and reflux at a temperature of 80°C to 100°C and stir for 10h to 12h to obtain a light yellow suspension;

[0031] The mass ratio of described chitosan and ammonium thiocyanate is 1:(0.5~1.0); The volume ratio of the quality of described chitosan and dehydrated alcohol is 1g:(5~10)mL;

[0032] 2. Centrifuge and filter the light yellow suspension to obtain solids, wash the solids with absolute ethanol, and dry them in an oven at a temperature of 40°C to 80°C to obtain light yellow powdered thiourea chitosan ;

[0033] 3. Add light yellow powdered thiourea chitosan to NaOH solution with a mass fraction of 10% to 20% to obtain a reaction solution, and then add CS to the reaction solution 2 , and at a tempera...

specific Embodiment approach 2

[0040] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass ratio of chitosan and ammonium thiocyanate described in step one is 1:0.944. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the quality of chitosan described in step one and the volume ratio of dehydrated alcohol are 1g:9.32mL. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com