Organic electroluminescent compound and organic electroluminescent device thereof

A compound, electroluminescence technology, applied in organic chemistry, electro-solid devices, electrical components, etc., can solve the problems of charge imbalance in the light-emitting layer, reduce device efficiency, difficult electron flow, etc., and achieve high luminous purity and good thermal stability. , the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

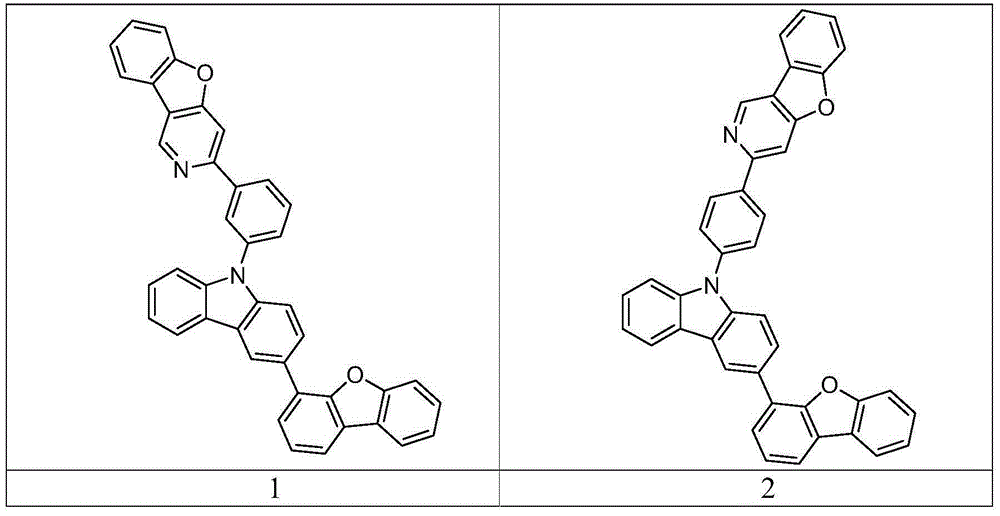

[0055] Synthesis of compound 1

[0056]

[0057] Synthesis of Intermediate 1-1

[0058] In a three-necked flask, add 3-bromocarbazole (24.5g, 0.1mol), 4-dibenzofuran boronic acid (21.2g, 0.1mol), potassium carbonate (27.2g, 0.2mol), 300ml tetrahydrofuran, 100ml water and Tetrakistriphenylphosphine palladium (0.5g) was heated to reflux under nitrogen protection for 12 hours, cooled, extracted with ethyl acetate, dried, concentrated, and the crude product was recrystallized with methanol to obtain 30.6g product with a yield of 92%.

[0059] Synthesis of intermediate 1-2

[0060] In a three-necked flask, add intermediate 1-1 (25g, 0.075mol), m-bromoiodobenzene (28.1g, 0.1mol), potassium hydroxide (5.6g, 0.1mol), cuprous iodide (1.9g), o-Phenanthroline (2.5g) and 300ml mesitylene, heated to reflux under nitrogen protection for 24 hours, cooled, removed the solvent under reduced pressure, added water and dichloromethane, separated, the organic phase was dried with anhydrous so...

Embodiment 2

[0066] Synthesis of compound 9

[0067]

[0068] In a three-necked flask, add intermediate 1-3 (2.5g, 5.5mmol), 3-chloro-benzothiophene [3,2-c] pyridine (1.3g, 6.0mmol), potassium carbonate (1.5g, 11mmol) , 30ml tetrahydrofuran, 10ml water and tetrakistriphenylphosphine palladium (50mg), heated to reflux under nitrogen protection for 12 hours, cooled, extracted with dichloromethane, dried, concentrated, and the crude product was separated by column chromatography to obtain 2.4g product, producing The rate is 73%.

Embodiment 3

[0070] Synthesis of Compound 19

[0071]

[0072] Synthesis of Intermediate 19-1

[0073] In a three-necked flask, add 3-bromocarbazole (24.5g, 0.1mol), 4-dibenzofuran boronic acid (22.8g, 0.1mol), potassium carbonate (27.2g, 0.2mol), 300ml tetrahydrofuran, 100ml water and Tetrakistriphenylphosphine palladium (0.5g) was heated to reflux under nitrogen protection for 12 hours, cooled, extracted with ethyl acetate, dried, concentrated, and the crude product was recrystallized with methanol to obtain 31g product with a yield of 89%.

[0074] Synthesis of Intermediate 19-2

[0075] In a three-necked flask, add intermediate 19-1 (25g, 0.072mol), m-bromoiodobenzene (28.1g, 0.1mol), potassium hydroxide (5.6g, 0.1mol), cuprous iodide (1.9g), o-Phenanthroline (2.5g) and 300ml mesitylene, heated to reflux under nitrogen protection for 24 hours, cooled, removed the solvent under reduced pressure, added water and dichloromethane, separated, the organic phase was dried with anhydrous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com