Lignocellulosic biomass direct pressurized liquefaction and ethyl levulinate directional preparation method

A technology of levulinic acid ester and pressurized liquefaction, which is applied in the field of biomass resource utilization, can solve the problems of large amount of solvent, low product purity, complicated process and the like, achieves easy recovery and reuse, simple method operation, and improved The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

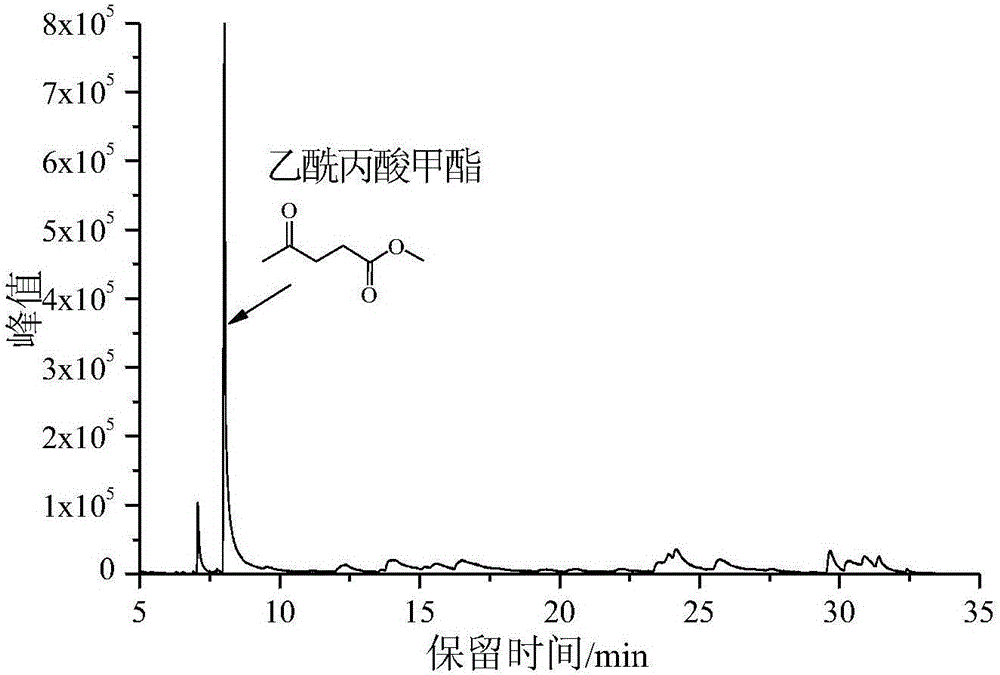

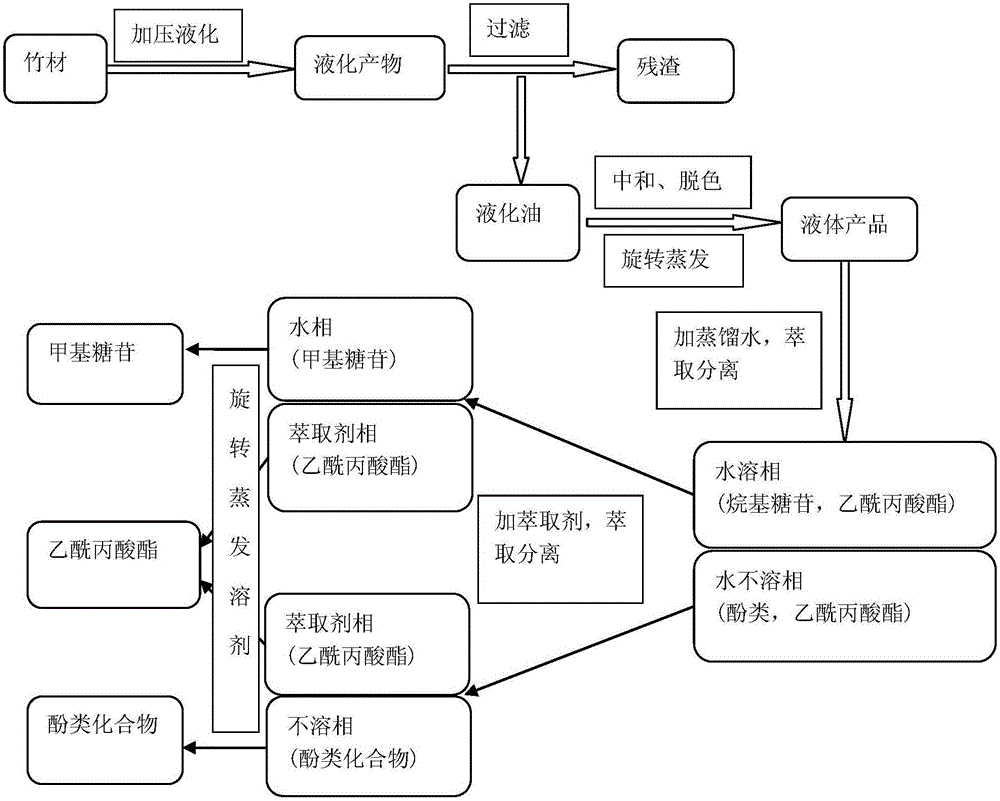

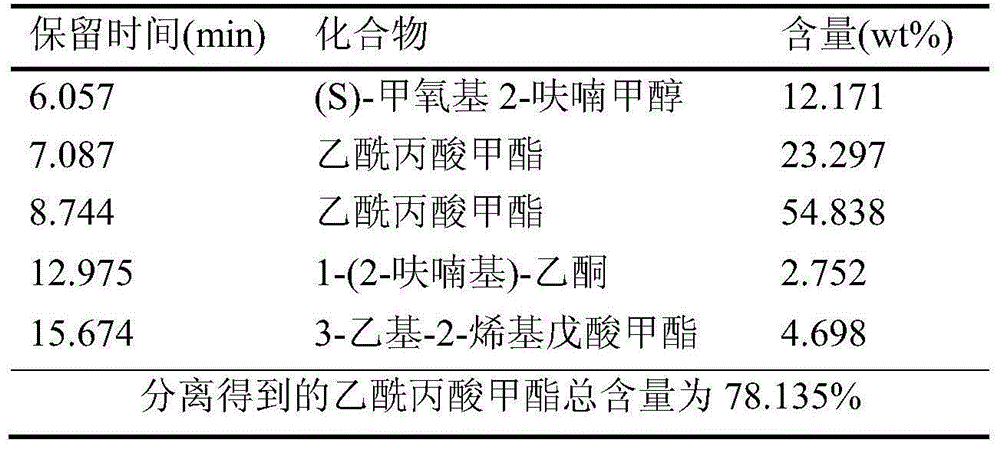

[0025] Weigh 40g of absolute dry weight bamboo, the particle size is 40-60 mesh, add 240g of methanol and 1.0g of sulfuric acid into an autoclave with a volume of 1L, and evacuate the air in the autoclave with nitrogen; at a heating rate of 3°C / min With a stirring speed of 500r / min, the temperature was raised to 200°C, and the pressure of the autoclave was 5MPa. After the reaction was kept for 60 minutes, the heating was turned off, and the cooling water was quickly passed through to cool down to room temperature within 1 to 5 minutes. After the liquefied product was neutralized and filtered, methanol was recovered by rotary evaporation under reduced pressure at 45° C. under a pressure of -0.09 MPa, and 80 g of distilled water was added, resulting in phase separation. 40 g of ethyl acetate was added to the aqueous phase, and after phase separation, the ethyl acetate extract was evaporated to dryness to obtain a part of levulinic acid ester compounds, and the remaining water ph...

Embodiment 2

[0027] Weigh 40g of absolute dry weight bamboo, the particle size is 40-60 mesh, add 400g of methanol and 1.0g of sulfuric acid into an autoclave with a volume of 1L, and empty the air in the autoclave with nitrogen; at a heating rate of 3°C / min With a stirring speed of 500r / min, the temperature was raised to 200°C, and the autoclave pressure was 7MPa. After the reaction was kept for 60 minutes, the heating was turned off, and the cooling water was quickly passed through to cool down to room temperature within 1 to 5 minutes. After the liquefied product was neutralized and filtered, methanol was recovered by rotary evaporation under reduced pressure at 45° C. under a pressure of -0.09 MPa, and 80 g of distilled water was added, resulting in phase separation. 40 g of ethyl acetate was added to the aqueous phase, and after phase separation, the ethyl acetate extract was evaporated to dryness to obtain a part of levulinic acid ester compounds, and the remaining water phase was ev...

Embodiment 3

[0029] Weigh 40g of absolute dry weight bamboo, the particle size is 40-60 mesh, add 240g of methanol and 0.4g of sulfuric acid into an autoclave with a volume of 1L, and empty the air in the autoclave with nitrogen; at a heating rate of 3°C / min With a stirring speed of 500r / min, the temperature was raised to 200°C, and the autoclave pressure was 5MPa. After the reaction was kept for 60 minutes, the heating was turned off, and the cooling water was quickly passed through to cool down to room temperature within 1 to 5 minutes. After the liquefied product was neutralized and filtered, methanol was recovered by rotary evaporation under reduced pressure at 45° C. under a pressure of -0.09 MPa, and 80 g of distilled water was added, resulting in phase separation. 40 g of ethyl acetate was added to the aqueous phase, and after phase separation, the ethyl acetate extract was evaporated to dryness to obtain a part of levulinic acid ester compounds, and the remaining water phase was ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com