A method for preparing 3,5-dimethylphenol

A technology of dimethylphenol and catalyst, applied in the field of preparation of 3,5-dimethylphenol, which achieves the effects of less pollution, reduced filling frequency, and reduced material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

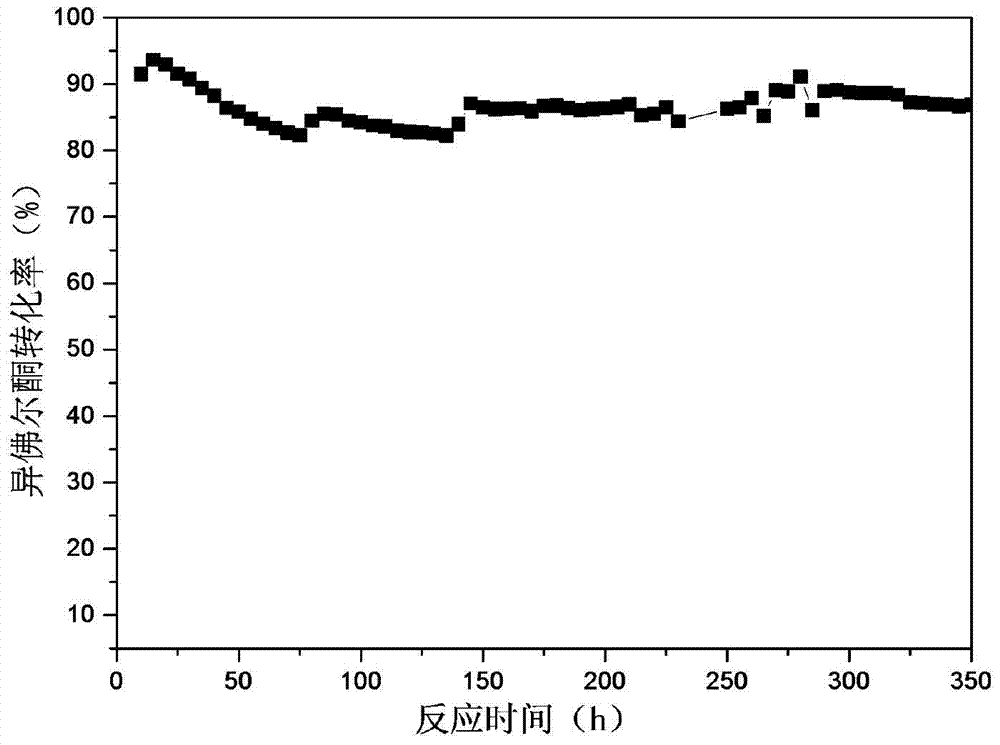

Image

Examples

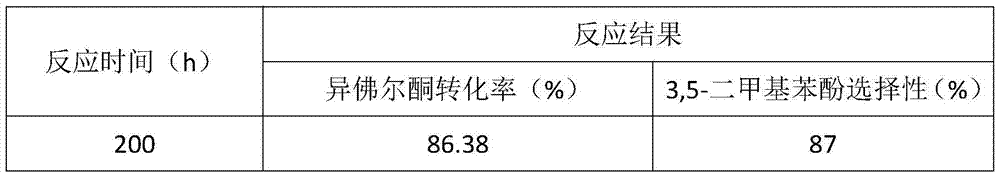

Embodiment 1

[0027] 1. Put the 20-40 mesh iron-nickel-chromium mixed oxide catalyst into the constant temperature zone of the stainless steel reaction tube of the fixed-bed microreactor.

[0028] 2. Use a metering pump to continuously inject the raw material isophorone into the catalyst bed of the fixed-bed microreactor, and carry out aromatization reaction with the iron-nickel-chromium mixed oxide catalyst. The reaction temperature is 450°C, the pressure is 1.5MPa, and the mass is empty. The speed is 0.5h -1 , the nitrogen flow rate is 20ml / min, and the reaction time is 5h, that is, the aromatization of isophorone catalyzed by iron-nickel-chromium mixed oxide is completed to prepare 3,5-dimethylphenol;

[0029] The iron-nickel-chromium mixed oxide catalyst described in this example is synthesized by a co-precipitation hydrothermal method, and the specific synthesis method is as follows: ferric nitrate nonahydrate, nickel nitrate hexahydrate, and chromium nitrate nonahydrate are mixed acco...

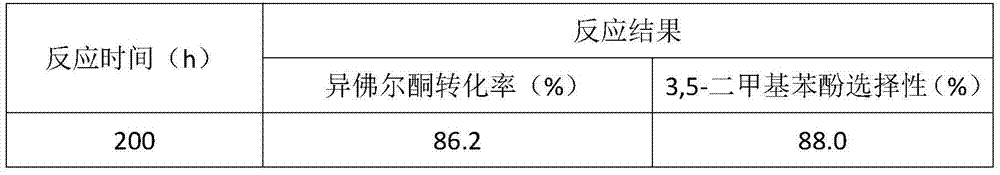

Embodiment 2

[0034] 1. Put the 20-40 mesh iron-nickel-chromium mixed oxide catalyst into the constant temperature zone of the stainless steel reaction tube of the fixed-bed microreactor.

[0035] 2. Use a metering pump to continuously inject the raw material isophorone into the catalyst bed of the fixed-bed micro-reactor, and carry out aromatization reaction with the iron-nickel-chromium mixed oxide catalyst. The reaction temperature is 600°C, the pressure is 5MPa, and the mass space velocity for 2h -1, the nitrogen flow rate is 60ml / min, and the reaction time is 5h, that is, the preparation of 3,5-dimethylphenol by the catalyzed isophorone aromatization of iron-nickel-chromium mixed oxide is completed;

[0036] The iron-nickel-chromium mixed oxide catalyst described in this example is synthesized by co-precipitation hydrothermal method, and the specific synthesis method is as follows: iron nitrate nonahydrate, nickel nitrate hexahydrate, and chromium nitrate nonahydrate are divided into i...

Embodiment 3

[0041] 1. Load the 20-40 mesh iron-nickel-chromium mixed oxide catalyst into the constant temperature zone of the stainless steel reaction tube of the fixed bed microreactor.

[0042] 2. Using a metering pump, the raw material isophorone is continuously injected into the catalyst bed of the fixed-bed microreactor, and the aromatization reaction is carried out with the iron-nickel-chromium mixed oxide catalyst. The reaction temperature is 570 ° C, the pressure is 2.5 MPa, and the mass is empty. Speed is 1h -1 , the nitrogen flow rate is 40ml / min, and the reaction time is 5h, that is, the iron-nickel-chromium mixed oxide catalyzed isophorone aromatization is completed to prepare 3,5-dimethylphenol;

[0043] The iron-nickel-chromium mixed oxide catalyst described in this example is synthesized by co-precipitation hydrothermal method, and the specific synthesis method is as follows: iron nitrate nonahydrate, nickel nitrate hexahydrate, and chromium nitrate nonahydrate are divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com