Device and method for comprehensive utilization of coal chemical gasification black water waste heat and pressure

A technology of coal chemical industry and black water, which is applied in the chemical industry, climate sustainability, heating water/sewage treatment, etc., can solve the problem of large amount of discharged sewage, achieve pressure and temperature reduction, good economic benefits and social environmental protection benefits , Solve the effect of scaling and sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

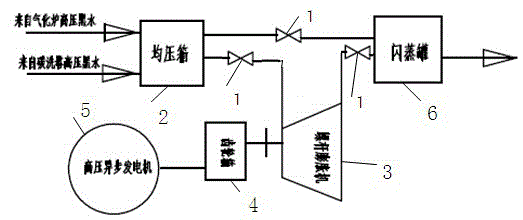

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] A device for comprehensive utilization of waste heat and pressure of coal chemical gasification black water, including a control system, including a pressure equalization box 2, a regulating valve 1, a screw expander 3, a gear box 4, a high-voltage asynchronous generator 5, and a flash tank 6; The pressure equalization box 2 is connected to the inlet of the screw expander 3 through the regulating valve 1, the bearing of the screw expander 3 is coupled to the gear box 4, and the gear box 4 is coupled to the high-voltage asynchronous generator 5; The outlet of the screw expander 3 is connected with the flash tank 6 through a pipeline.

[0021] The control system described is a manual control mode.

[0022] The control system is an automatic control mode, specifically a PLC controller.

[0023] The control system can realize manual and automatic switching without dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com